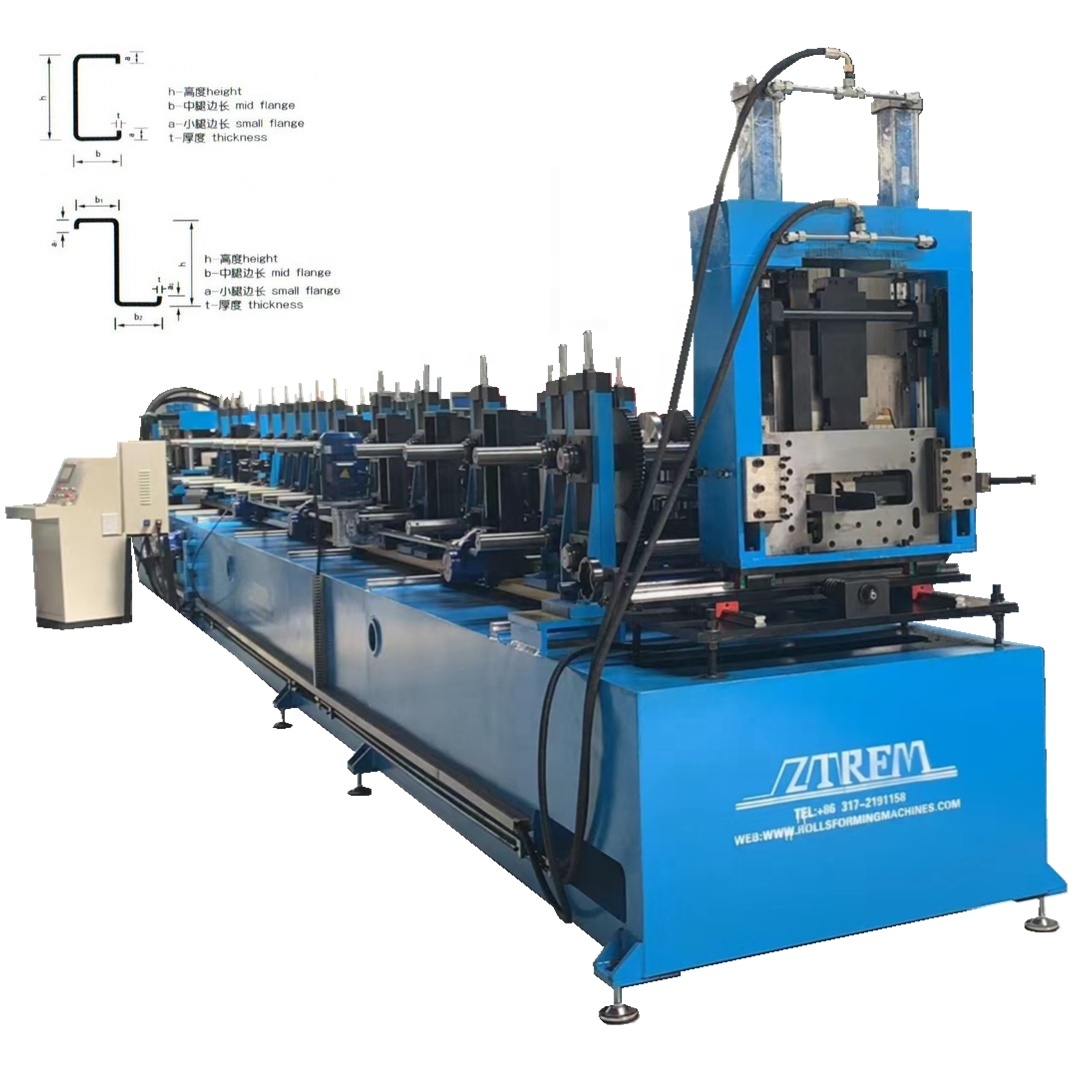

How to test C Z purlin roll forming machine quality ?

We made a full automatic machine for Brazil customer, the machine completed this month, and we tested the machine and here let me share the test report with you:

Customer personal requirement:

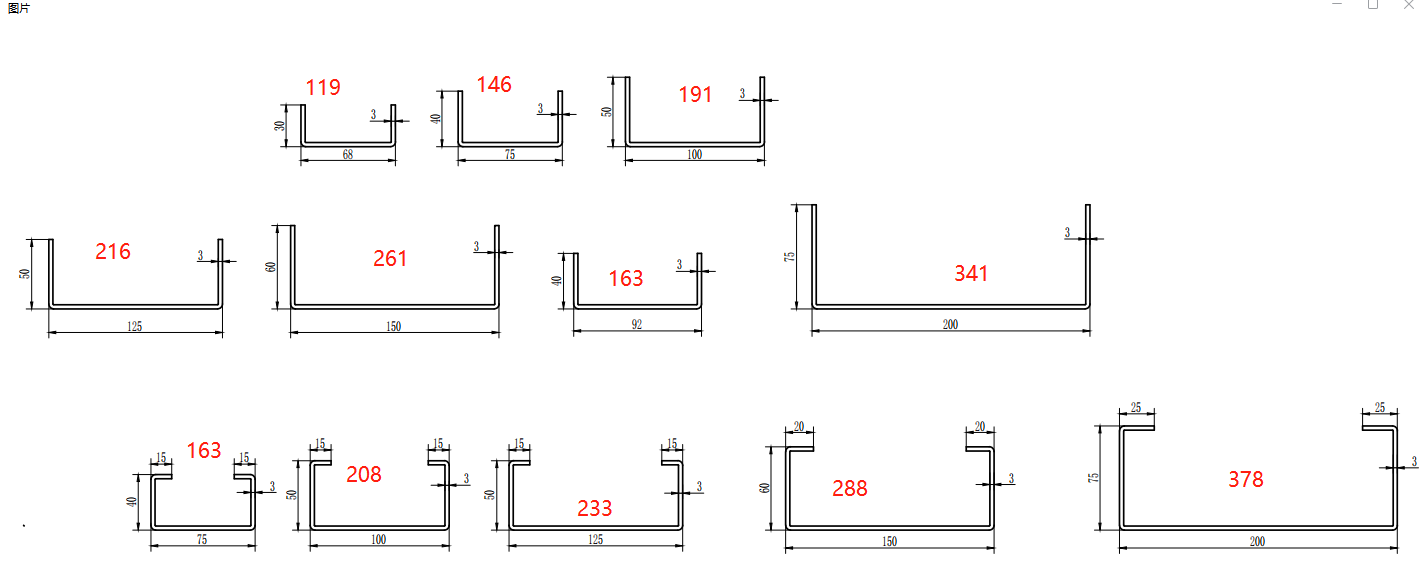

This machine can make products as below:

C purlin bottom width 75-200mm

U purlin bottom width 65-200mm

C purlin lip size 15-25mm

CU purlin height 30-80mm

Above red number is the input material width for 3mm thickness.

Our machine have function to make the rib on the bottom of the purlin, you can choose to use this rib forming function or do not use this rib function:

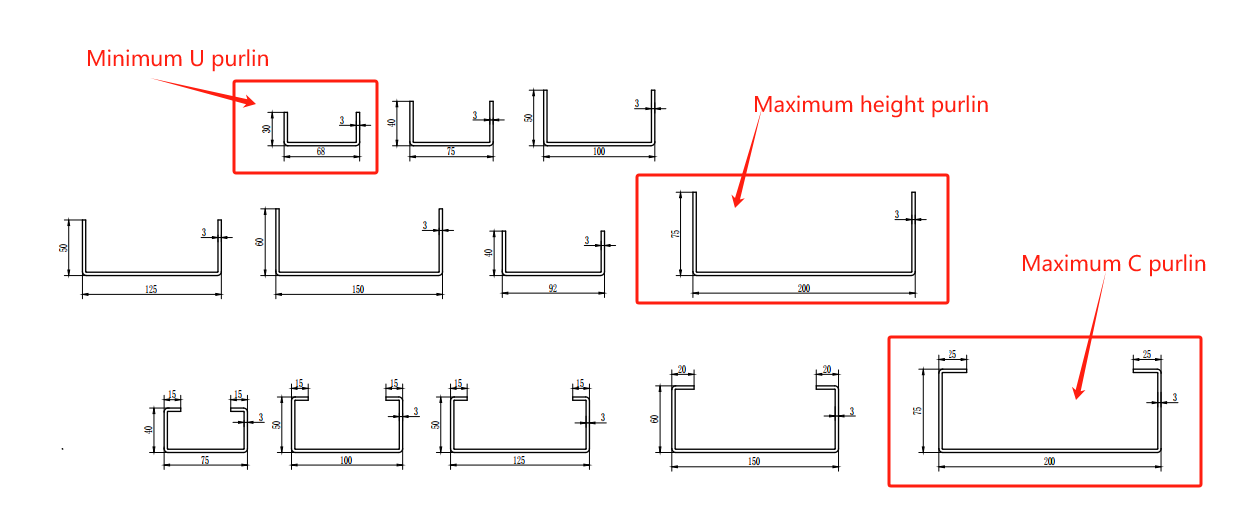

We tested 3 profiles to guarantee the machine is performance well:

As our experience if the below 3 profiles can make well then other profiles is no problem to make on the machine.

Results of the 3 profile testing:

68x30x3.0mm U purlin:

190x75x3.0mm U purlin:

200x75x25x3.0mm C purlin:

Our c purlin machine roll forming machine advantages:

- Servo motor drive, more accurate start and stop, faster speed.

- Intelligent control system, can realize remote monitoring and operation and maintenance.

- The operation interface uses a notebook instead of an electric control cabinet.

- With fast input software, USB import can be realized.

- Dual automatic type change (two modes: button and PLC screen).

- Unlimited shearing blade and do not need to change the blade frequently.

7.Profile sizes change is quick, normally change time within 5 minutes.

Here share some of our machine photos with you: