High Quality Weight 8000 lbs., size 21′ x 4′ x 3′ and 12″ Ridge Cap with/Open hems roll former

Ridge cap Roll Former

- Loaded on your truck.

- 220V 3 phase

- Weight 8000 lbs., size 21′ x 4′ x 3′

- Ridge Cap Roll Former – Hems both sides of Cap

- Computer Batch Control

- Hydraulic Shear

- Includes 5,000 lb. manual un-coiler

Ridge cap roll forming machine | cap ridge roll forming machine | capping roll forming machine | roof ridge cap roll forming machine | hat cap roll forming machine | top hat cap machine

Ridge cap roll forming machine popular sell in many countries, we make cap ridge machine as customer’ drawing. Material common is PPGI material, material thickness common between 0.3-0.8mm.

Details Of Roof Ridge Cap Roll Forming Machine

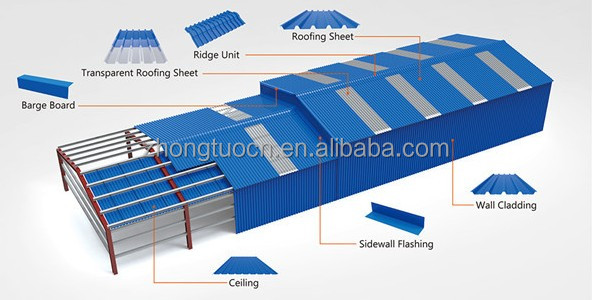

Ridge cap forming machines are tailored to manufacture ridge caps that are compatible with steel roofing sheets. Certain models produce standard ridge caps featuring flat edges, which necessitate trimming to align with trapezoidal roofing sheets at the time of installation. In contrast, specialized ridge caps come pre-cut to perfectly match trapezoidal sheets, thus removing the need for on-site adjustments. This innovative design not only enhances installation efficiency but also guarantees a flawless waterproof seal with the roofing panels.

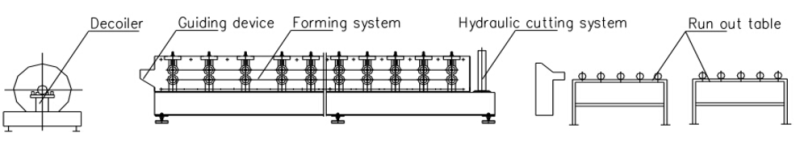

Among the widely used ridge cap roll forming machines are the “stop-and-cut” models, known for their operational speed of around 12 to 15 meters per minute, and the hydraulic fly-cutting variants capable of achieving speeds up to about 20 meters per minute. A typical setup of a ZTRFM ridge cap forming machine comprises a 5-ton manual uncoiler, a forming section equipped with post-cut functionality, a PLC control system, a hydraulic power pack, and a delivery table. Advanced control systems from brands like Mitsubishi or Siemens improve user experience by allowing operators to easily input length and quantity requirements, after which the machine handles the rest automatically.

Moreover, these forming machines are designed for minimal maintenance, needing only regular lubrication of the cutting mechanism to maintain optimal performance day-to-day.

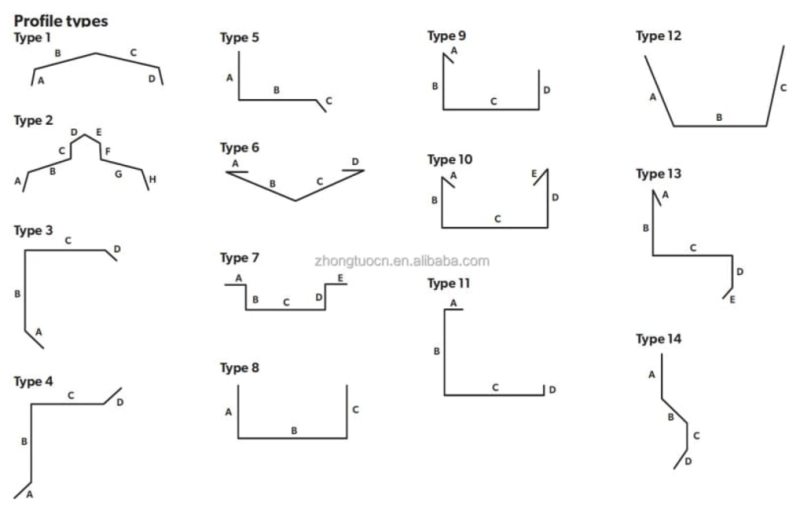

Profile drawing:

Working flow:

The Application of The Ridge Cap:

The Technical Specifications Of The Ridge Cap Machine Machine:

| NO | Name | Specifications |

| 1 | Raw material | Galvanized steel |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5 ton manual decoiler |

| 4 | Roller station | 22 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 70 mm |

| 7 | Work speed | 0-15 m/min |

| 8 | Transmission | by double chains transmission |

| 9 | Motor power | 5.5 kw motor |

| 10 | Machine frame | 350# H steel welded |

| 11 | Cutting type | Hydraulic fly cutting |

| 12 | Cutting blade material | Cr12 with quenched treatment |

| 13 | Hydraulic motor power | 3KW |

| 14 | Control system | PLC |

| 15 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

More Pictures of the Machine:

、、

、、