ZTRFM ISO CE certificate Europe Used Steel Decking TR220 Floor deck making machine roll forming machine

ZTRFM ISO CE certificate Europe Used Steel Decking TR220 Floor deck making machine roll forming machine

Description of TR220 profile deck machines

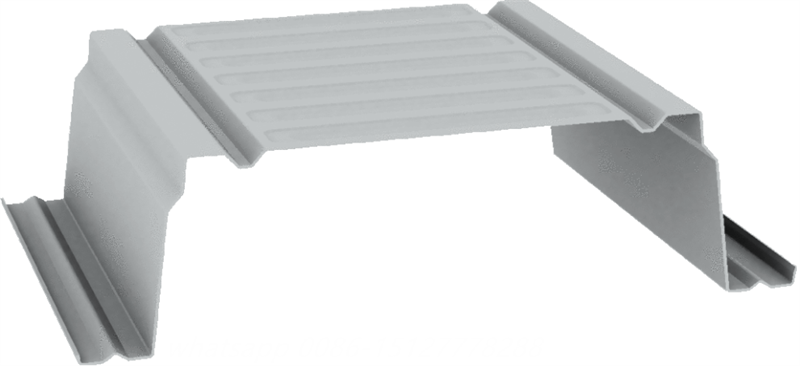

The TR220 composite floor system merges the robust qualities of a 220mm deep steel deck profile with the efficiency of a ribbed reinforced concrete slab, delivering an effective long-span floor solution. By installing the TR220 on the bottom flanges, a slimmer floor construction is achieved, minimizing the structural depth and eliminating the need for intermediate supports.

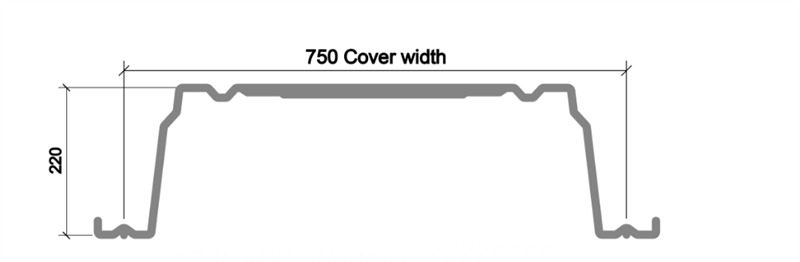

TR220 Profile drawing:

TR220 Roof Decking Description

- Deck Type: TR220 deck

- Benefits:

- Un-propped spans can reach up to 6 meters.

- It is lightweight in comparison to alternative long-span flooring options.

- This solution decreases the structural floor zone by utilizing the slab depth within the beam web.

- Gauges:1.13mm,1.25mm

- Specification:750mm cover width,220mm deep

Metal Decking continues to provide the best fast-track, flexible, and financially-effective solution for suspended floor slabs in steelwork construction.

ZHONGTUO Deck Machine Services providing a solution for all suspended floor slab requirements, including concreting on metal decking and roof decking machine.

ZHONGTUO Machinery provides metal deck machines, ZHONGTUO Machinery is also capable of manufacturing other types of metal deck roll forming machines, such as the floor deck TR60+, TR 80 and among others.If you have any interest in these machines, please don’t hesitate to contact ZHONGTUO Machinery for more information.

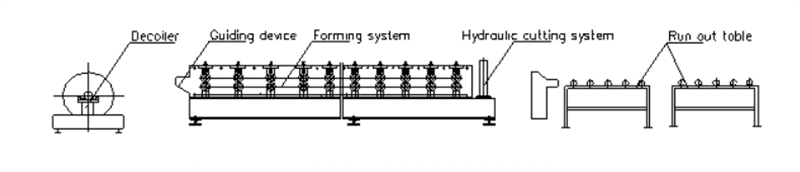

Work Flow of the Decking Machine:

Decoiler→Feeding Device→Embossing→Roll Forming System→Hydraulic Cutting System→Exit Rack

Floor Deck TR220 Roll Forming Machine |

||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):0.8-1.5mm |

| B) S450 | ||

| C) S450 | ||

| Yield strength : | 350 – 450 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | according to your requirement (Optional) |

| Forming station : | 34 stands | |

| Decoiler : | Manual decoiler | Hydraulic decoiler (Optional) |

| Punching system | No | Hydraulic punching or Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | Siemens |

| Driving system : | Chain drive | Gearbox drive (Optional) |

| Machine structure: | Wall panel station | Forged Iron station or torri stand structure (Optional) |

| Rollers’ material : | GCr15 | |

| Cutting system : | Post-cutting | Pre-cutting (optional) |

| Power supply : | 380V 50Hz | according to your requirement |

| Machine color : | Industrial blue | according to your requirement |

More pictures of the machine: