Australia Trimdek Sheet Roll Forming Machine Sheet Roll Forming Machine For Making TRIMDEK Roof Sheets and Walling,Designed to withstand Australia’s tough climate

Description Of Australia Trimdek Sheet Roll Forming Machine

The Trimdek sheet roll forming machines comply with Australian safety standards and are manufactured in China. The Trimdek roofing profile features a long-span design that allows for wide support spacing, making it a versatile, lightweight, yet robust option for cladding.

With a sheet coverage of 760mm, Trimdek is both economical and quick to install. Its 28mm rib height, combined with a specially designed capillary groove, ensures effective watertightness, even on roofs with a pitch as low as two degrees.

Sheet Coverage Details:

– Cover width: 762mm

– Actual sheet width: 820mm

– The standard thickness for Steel sheets ranges from 0.42 to 0.48 BMT

Additionally, popular Australian profiles include corrugated roofing, Kliplok 700, and Spandek. Australia typically uses harder materials with a yield strength of 500 MPa to enhance the durability of roofing products. However, these harder materials can be more brittle, making them prone to breakage during the forming process.

ZTRFM Machinery Factory has extensive experience in designing and manufacturing roll forming machines, including those for gutters, fascia, and C purlins, specifically tailored for the Australian market.

ZTRFM Machinery Factory specializes in designing roofing machines tailored to your specific roofing profile or design. The advantages of pre-engineered metal buildings include:

- Exceptional durability

- Ability to withstand severe conditions

- Cost-effectiveness

- Low initial investment and minimal maintenance costs

- Environmentally friendly design

- Complete recyclability of materials

- Flexible design options

- Easy relocation capabilities

- Significantly reduced installation time

These buildings are easy to operate and feature automated functionality controlled by a PLC system.

Profile Drawing:

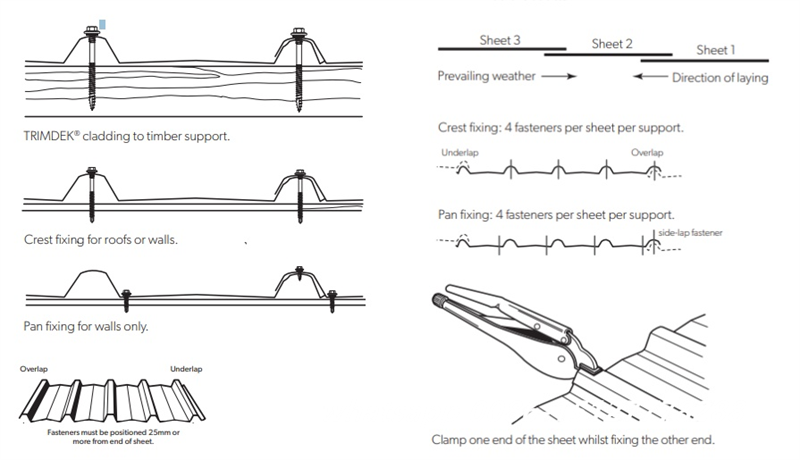

INSTALLATION:

FASTENING SHEETS TO SUPPORTS

The TRIMDEK profile is designed to be pierce-fixed to either timber or steel supports, meaning that the fastener screws penetrate through the sheeting. For optimal watertightness, it is recommended to position roof screws through the crests of the profile. When installing wall cladding, screws can be placed in either the crests or the pans.

Ensure that screws are driven perpendicular to the sheeting and centered within the corrugation or rib. Avoid placing fasteners within 25mm of the sheet ends.

Side Laps

The edge of the TRIMDEK cladding featuring the anti-capillary groove serves as the underlap. While it is typically good practice to use fasteners along side laps, they are often unnecessary for strength when the cladding is supported as per the maximum support spacing guidelines.

Laying Procedure

Before lifting the sheets onto the roof, assess which end of the building is the most suitable to begin installation. Verify that the sheets are oriented correctly, with the overlapping edge facing the installation starting point. It is safer and more efficient to orient sheets on the ground rather than on the roof. Position bundles of sheets over or near stable supports rather than at the mid-span of roof members.

Industry standards suggest commencing the laying of sheets from the end of the building that aligns with the prevailing weather conditions whenever possible. For more comprehensive information, please refer to the LYSAGHT Roofing & Walling Installation Manual.

Typical Applications:

TRIMDEK Roof Sheets and Walling – Durable and Energy-Efficient

TRIMDEK ZTRFM steel roofing and cladding is a secure, durable, and energy-efficient choice for both residential and commercial projects. Designed to withstand Australia’s tough climate, TRIMDEK offers long-lasting performance and modern style.

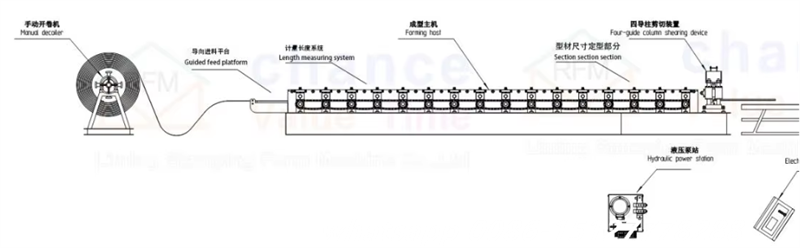

Working Flow chart:

Steel coil uncoiling → steel plate feeding → shape forming → size setting → hydraulic cutting-finished product splicing

The Technical Specifications Of the Australia Trimdek Sheet Roll Forming Machine :

|

Australia Trimdek Sheet Roll Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 0.3-0.7mm | ||

| Decoiler | Roller station | 20-22 station | The standard one to match the production line |

| According to customer’s requirement | |||

| Loading capacity | 7.5 Tons | ||

| Coil inner diameter | 450-600 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 75 mm | ||

| Roller material | GCr12MoV | ||

| Rolling station | 18 stations | ||

| Work speed | 15-20 m/min (without punching holes) 0-20m/min (with holes) | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Chinese famous brand Harbin | Famous brand of Harbin | |

| Work power | 7.5 kw+3kw | ||

| Transmission | Gear box transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

|

| Decoiler, we can change to hydraulic one if you need. | |||

More pictures of the machine: