High Load Bearing Capacity Warehouse rack P beam Roll Forming Machine for the Manufacture of Shelf Storage P Beam

Producing Shelf Storage P-Beam Roll Forming Machine

Shelf P shaped beam forming machine is a beam equipment used to produce shelf series components.

P beams are mostly used in warehouses, supermarkets, and large and small shopping malls for cargo display, display, and product display.

Zhongtuo P beam roll forming machine can produce products of various specifications with one piece of equipment. There are 26 sets of rollers in the forming part.

You only need to replace 6 sets of them, and by adjusting the outer cable mother and other sets of rollers, you can make various types of changes.

A double-group argon arc welding unit is installed for spot welding operations, and a high-speed burr-free cutting saw is used for the shearing part.

In order to ensure the production capacity of the equipment, argon arc welding, cutting saws and discharge racks are all connected by servo tracking.

Shelf Storage P-Beam

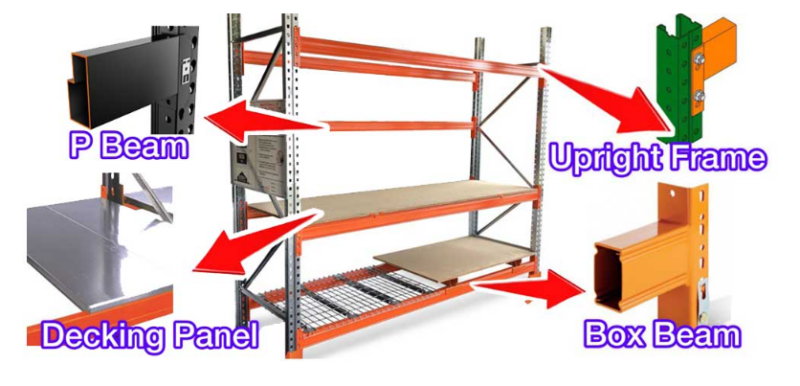

The P-beam is a crucial element of any shelf storage system, serving as the primary support structure in the storage racking industry. It consists of two main parts: the central beam and the hanging bracket, which are typically joined through welding. Depending on the cross-sectional design, beams can be categorized into rectangular, P-shaped, J-shaped, or double C-welded profiles, with the latter offering enhanced rigidity and torsional resistance. Connection methods vary, with options for open or integrated styles. The wall thickness of these beams generally ranges from 1.5 to 2.5 millimeters, and welding techniques include centered, flat-top, fully flat-top, flat-bottom, and fully flat-bottom welds. The length of the beam can be customized based on the specific storage requirements and load-bearing needs of the application. Beam dimensions are determined by calculating the maximum load that the beam must support.

These beams,characterized by their distinctive “P”cross section,provide strong structural support and are widely used for their high load bearing capacity and ease of installation.

Pallet Racking Systems:Manufacturing of P beams used in the construction of pallet racking systems.

Industrial Shelving:Production of beams for heavy-duty shelving units.

Construction:Structural components for buildings,including support

beams and frameworks.

Storage Solutions:Beams for warehouse and distribution center storage

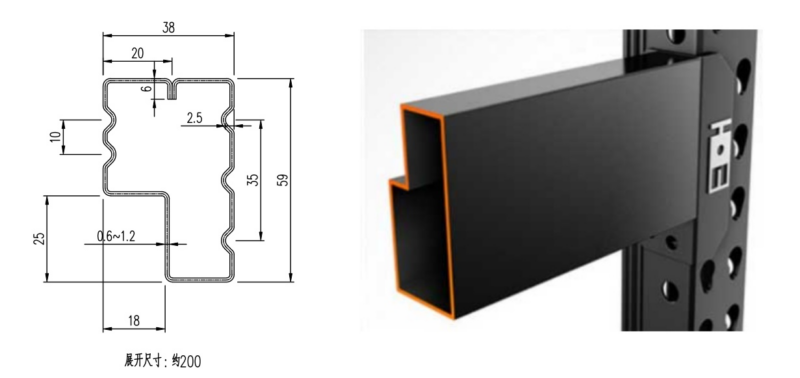

Profile Drawing:

Technology Processing Flow- P Profile beam Roll Forming Line:

Decoiling – Leveling – roll forming- servo follow spot welding – Cold saw cutting – Receiving table

The Technical Specifications Of the P Beam Roll Forming Machine:

| Warehouse rack P beam Roll Forming Machine | |||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 0.6-1.2 mm | ||

| Decoiler | Roller station | 7 rollers | The standard one to match the production line |

| upper 3 + down 4 to level the coil. | |||

| Loading capacity | 3 Tons | ||

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 60 mm | ||

| Roller material | Cr12 HRC 56-58 | ||

| Rolling station | 18 stations | ||

| Work speed | 10-15 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Work power | 7.5 kw+7.5 kw (two motors driving) | ||

| Transmission | Chain transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

More pictures of the machine: