ZT-840/860 Double Plate Colored Steel Roll Forming Machine

ZT-840/860 double plate colored steel roll forming machine

A detailed description:

ZT-840/860 double plate colored steel roll forming machine be perfect together of two models ,Reasonable structureBeautiful shape.It has to save floor space, simple operation,Particularly suitable site and on-site construction of small customers

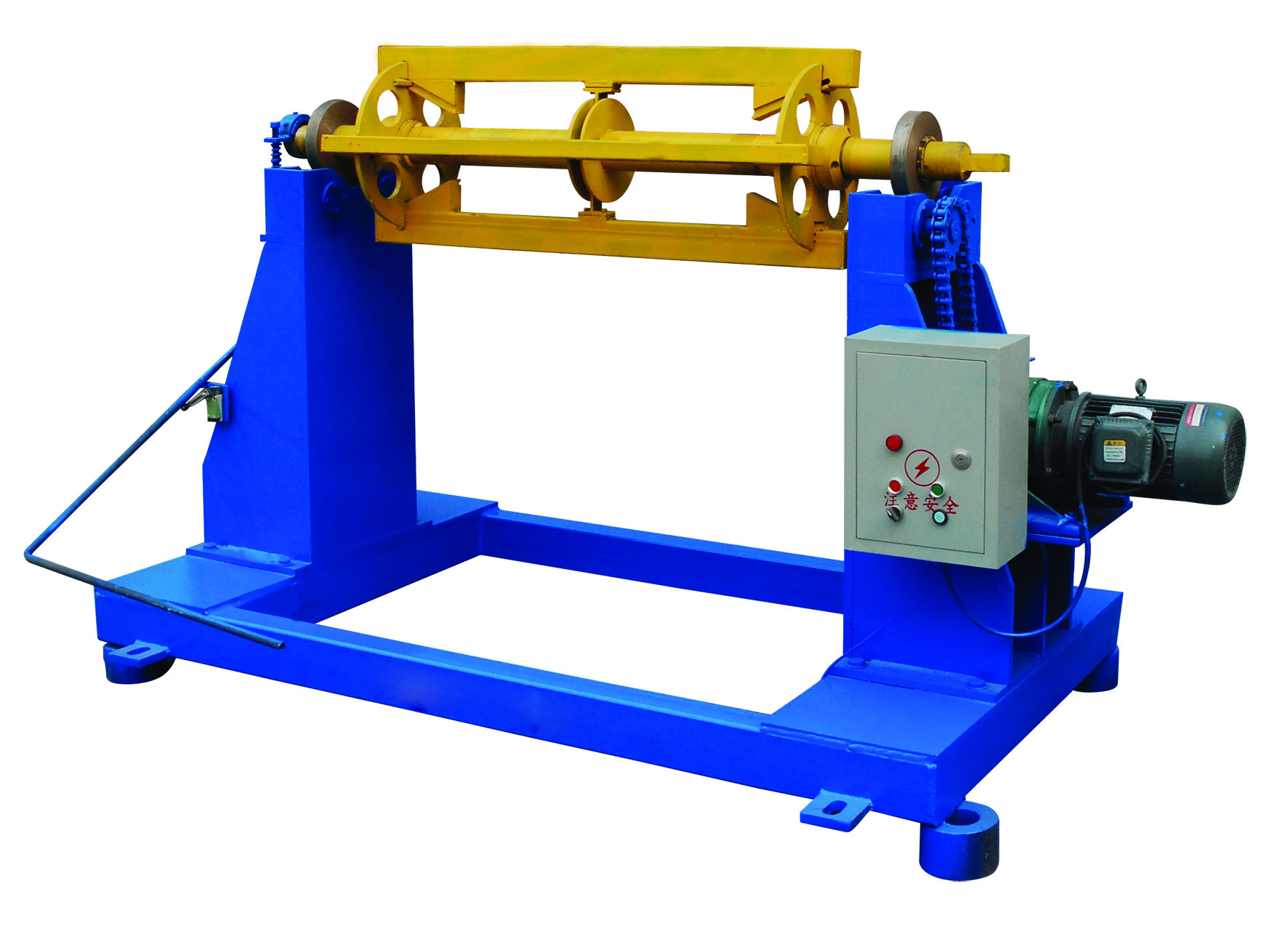

the main part of ZT-840/860 double plate colored steel roll forming machine have Importing platform, forming the host, forming cutting device, hydraulic station, computer control system composed of several parts.Optional equipment ordinary discharge machine, hydraulic discharge machine

Simple conversion operation on the lower,Simply by switching the button to convert the cabinet on each layer separately control,Power can also be controlled separately for each layer through the clutch,Optional equipment ordinary discharge machine, hydraulic discharge machine.

The main technical parameters of ZT-840/860 double plate colored steel roll forming machine :

- Mounting dimensions:10000mm—1700mm—1500mm

- Molding channel number:11/11

- Roller material:45#steel

- Rollers plating thickness:05mm

- Cutter Material:Cr12

- Forming speed:9-10m/min.

- Electronic Control System:Industrial computer PLC control

- Host power:3KW

- Hydraulic power station:3KW

- Sheet thickness:0.4-0.7mm

- Expand the width of the sheet:914mm

Warranty:

- One year, and we will provide the technical support for the whole life.

- Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

- Need one

- Training time: one week (contains the time of installation andadjustment)

The main characteristic of production line:

- The high of safety performance—-Can avoid the industrial accident and safety hazards of the traditional process shearing,slitting,punching,bending and so on.

- The high of production efficiency—-can save human and managemen aspects,material resource,reduce intermediate links operations in the multi-channel . it can improve 5-10 times than the traditional process

full Automatic—PLC computer control, simple operation, without manual calculation bracket profile pitch and length dimensions. Fully automated production line, without human intervention

The high precision of exterior—than manual punching, bending production of high dimensional accuracy of profiles, more unified and beautiful appearance.