Advanced Roller Shutter Slat Roll Forming Machines: Precision Engineering for Durable Security Systems

Description of the Roller Shutter Slat roll forming machine

The Cangzhou Zhongtuo Roller Shutter Slat Roll Forming Machine is engineered to produce a wide range of roller shutter slats, including PU slats (fire curtains) and Venetian blinds, suitable for a variety of applications such as garage doors, commercial shutters, fire doors, industrial facilities, public offices, kiosks, pavilions, and windows. This machine can process materials such as galvanized steel, stainless steel (304 and 316), and aluminum, with thicknesses ranging from Gauge 16 to Gauge 24 (commonly used in the U.S.) or 0.6mm to 1.5mm for international standards.

The machine is capable of producing popular profiles such as flat slats, curved slats, perforated slats, 55, 77, and 90 foam slats, and Venetian blinds in C50, C80, and Z90 sizes.

Cangzhou Zhongtuo offers customized roller shutter slat roll forming machines tailored to meet high-precision demands, ensuring smooth, burr-free surfaces and accurate punching. For micro-perforated slats, we can achieve hole spacing tolerances as tight as 0.3mm using a servo feeder system. Additionally, our machines can manufacture various accessories, including octagonal tubes, slat door rails, guide channels, and different types of bottom bars (I, T, and L shapes). Regardless of the line you choose, ZTRFM Machinery guarantees the production of high-quality, reliable profiles.

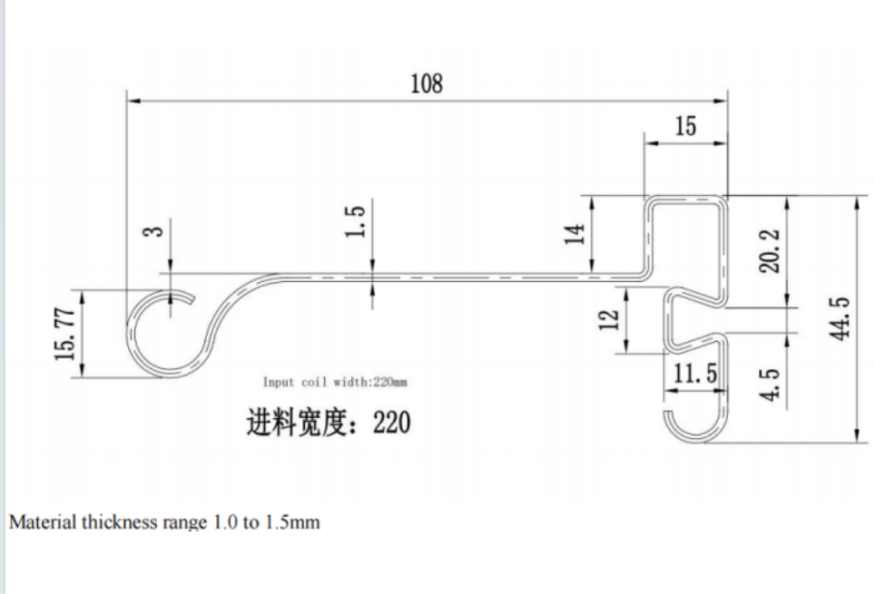

Profile drawing:

Application pictures of rolling shutter door structures:

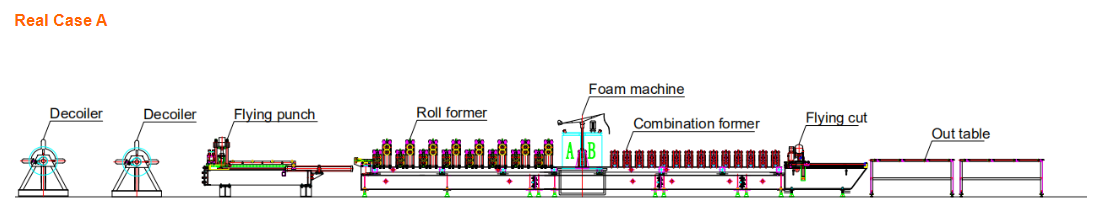

Flow chart:

Case A and Case B feature Description:

Both Case A and Case B are equipped with advanced IPC and PLC control cabinets, featuring 20GB of memory and software capable of programming and managing a full batch of standard jobs. This state-of-the-art control system is currently being rolled out across all Linbay roll forming machines.

In Case A, the system is fine-tuned for the production of foam shutter slats, ensuring seamless operation with a processing speed of around 10m/min.

Case B, on the other hand, is specifically designed for double-row shutter slats, enabling the machine to produce two profiles simultaneously. It incorporates three types of center punches and two variations of end lock holes, as well as micro-perforation capabilities, operating at a speed of 8m/min.

The Technical Specifications Of Rolling Shutter Door Machine:

These slats are later assembled to create the complete door. Now let me introduce more details about our Saudi type Australia rolling shutter door machine.

|

Part 1: Manual Decoiler |

|||||||

|

Decoiler |

A. Work type: passive | ||||||

| B. Structure: Steel channel welded for the basic frame | |||||||

| C. Usage: To support the coil and make the uncoiling | |||||||

| D. Brake system: manual | |||||||

| E.Max coil width: 300 mm | |||||||

| F.Inner diameter: 450-550mm(manual adjustment) | |||||||

| G.max capacity: 3 tons | |||||||

|

|||||||

| Part 2: Main roll former | |||||||

|

Roll forming machine |

Feeding device | Feeding width is adjustable with hand wheel | |||||

| One set roller to carry and feed the sheet at the beginning | |||||||

| Rolling shaft | Shaft material:45# STEEL | ||||||

| Shaft diameter: 60 mm | |||||||

| Tempering treatment to prevent deformed and improve hardness | |||||||

| Roller | Gcr15, heat treatment and quenched HRC58-62° | ||||||

| Rolling station | 27 rolling stations | ||||||

| Work speed | 5-12 m/min | ||||||

| Machine structure | Cast iron structure | ||||||

| Machine basic frame | Square pipe welded with panel cover | ||||||

| Work power | 18.5 kw | ||||||

| Rolling spacer | Anti rusty treatment | ||||||

| Transmission | By gear box | ||||||

|

|||||||

| Part 3: PLC control system | |||||||

|

Control system |

Frequency brand | Delta (original) | |||||

| PLC brand | Delta (original) | ||||||

| Frequency brand | Delta (original) | ||||||

| Screen type | Touch screen, also have buttons on the panel | ||||||

| Screen language | English/Chinese | ||||||

| Low pressure electric part | Schneider brand | ||||||

| Encode | Omron brand | ||||||

| Part 4: Cutting system | |||||||

|

Cutting system |

Work type | Fly saw cutting | |||||

| Driving method | Non stop cutting, servo motor 1.2 KW | ||||||

| Motor power | 5.5 kw | ||||||

| Cutter material | Cr12 with heat treatment | ||||||

| Cutting length tolerance | ±1mm/3m | ||||||

| Cutting feature | Without deformation | ||||||

| Part 5: Product table | |||||||

|

Product table |

Length | 3 meters | |||||

| Width | 0.8 meter | ||||||

| Material | Square pipe welded, with 8pieces passive rollers on the stable | ||||||

|

|

||||||