Basic Knowledge of Cold Roll Forming Machinery

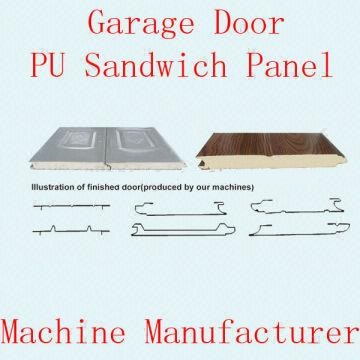

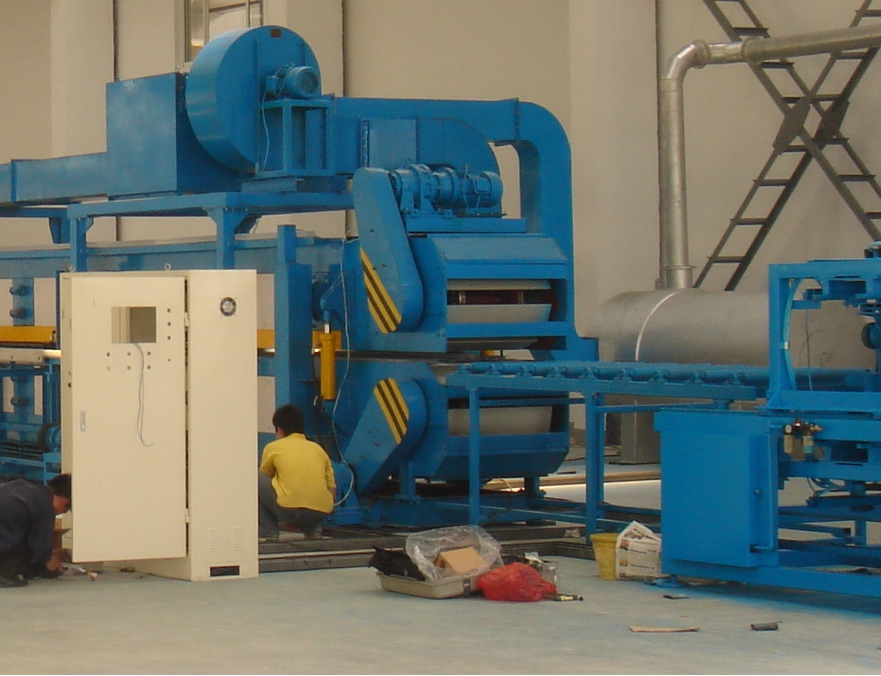

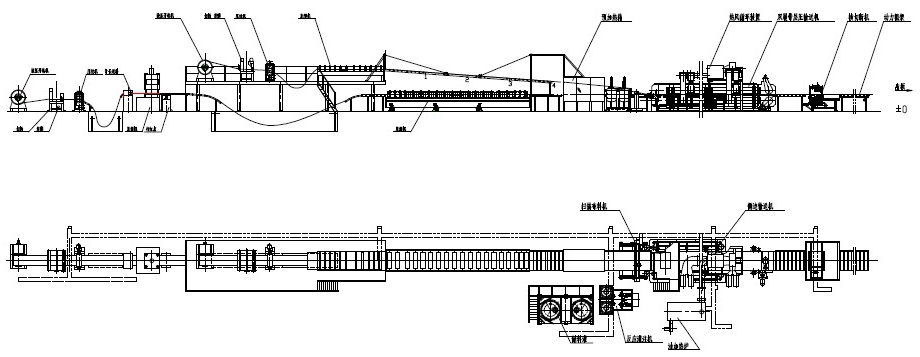

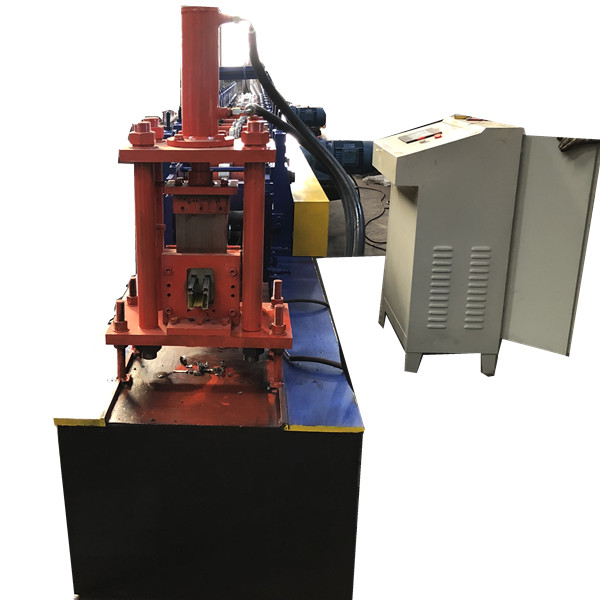

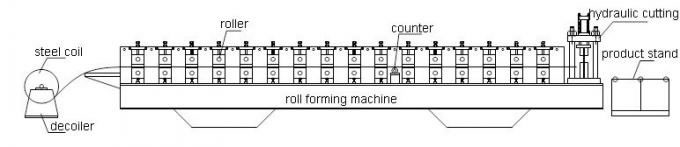

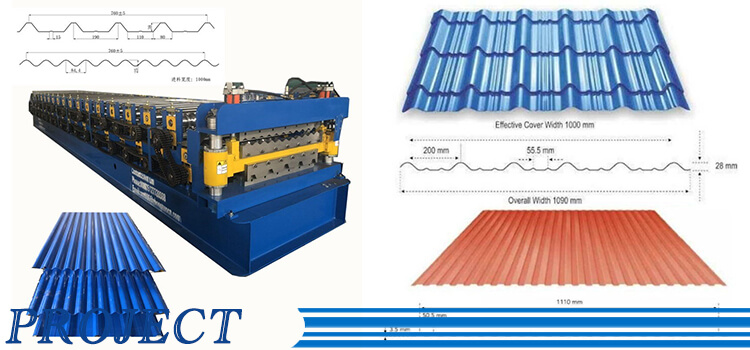

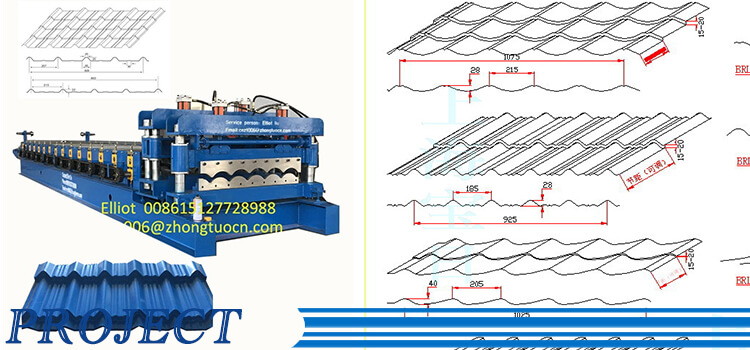

The process of cold roll forming of profiles is similar to the bending process. It is not a pure rolling process, but a special production method. The profile manufactured by this method has thin walls and small weight but has high rigidity and complex shape. The main equipment for the production of cold-formed profiles is the cold-formed forming unit, and there are many classification methods. The forming machine can be divided into profile forming machine and electric welded pipe forming machine according to the products produced; according to the frame type, it can be divided into cantilever forming machine and gantry forming machine. According to the structure of the forming machine, it can be divided into a roll forming machine, a row roll forming machine, and a crawler forming machine.

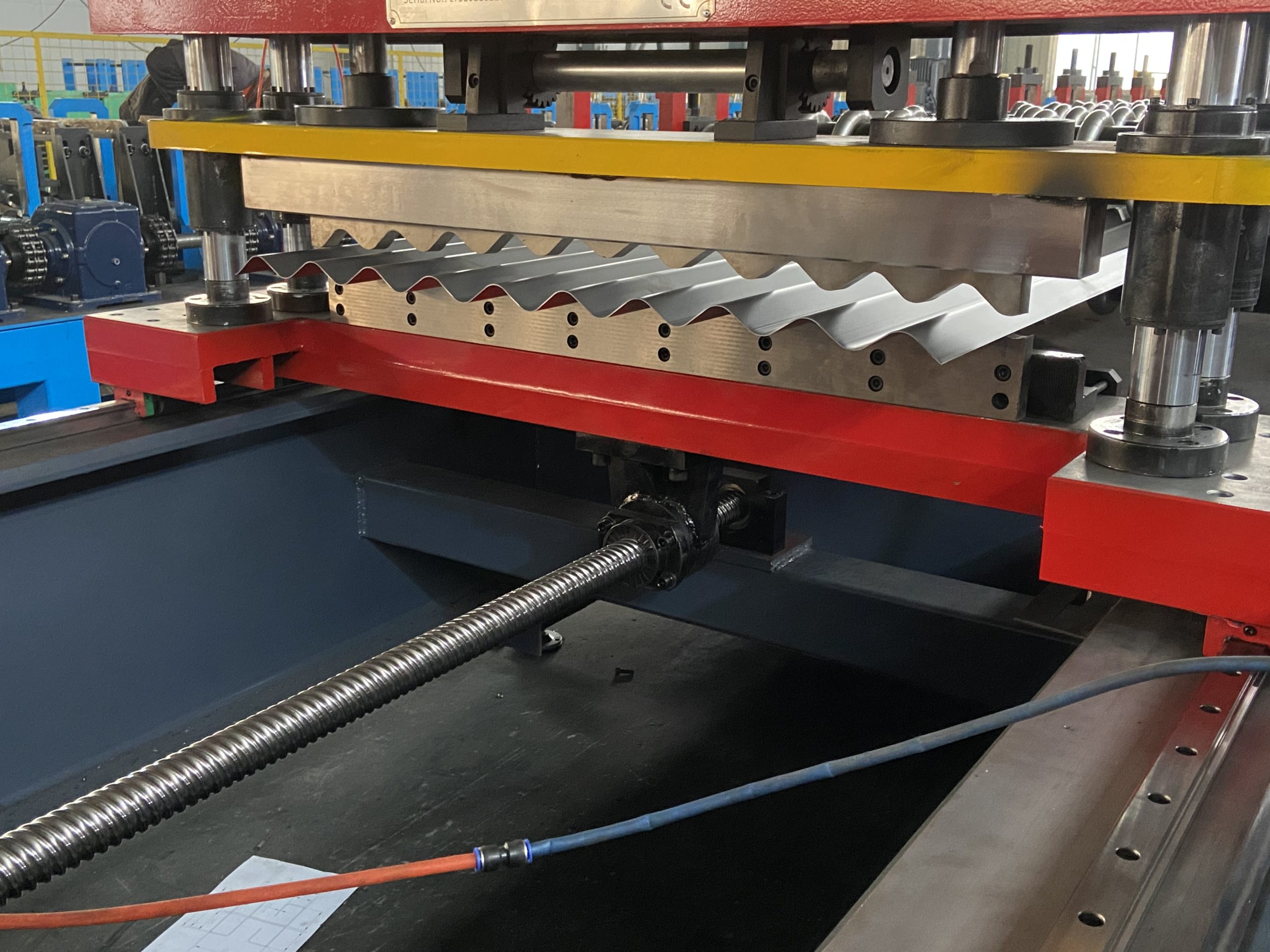

The horizontal roller is the transmission frame and undertakes the main task of tube blank deformation. Vertical rollers are passive, set up between two horizontal rollers or in groups. The main function is to guide and also participate in partial deformation and prevent the deformed strip from springing back.

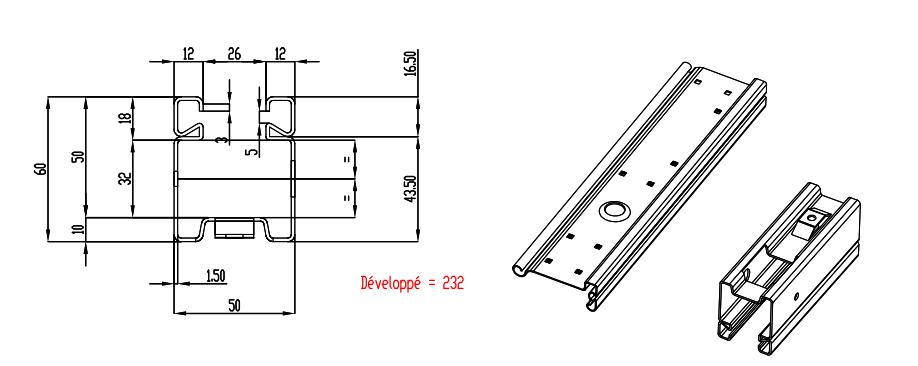

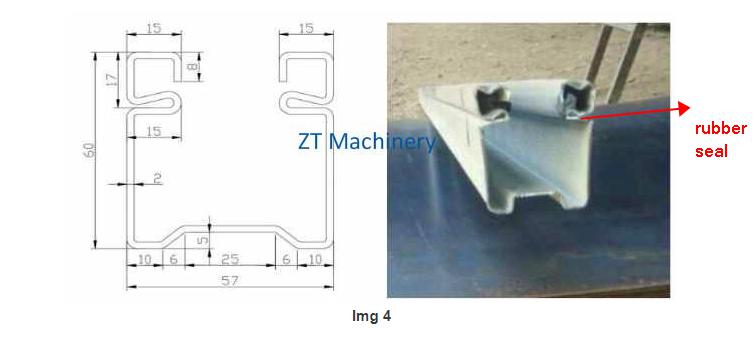

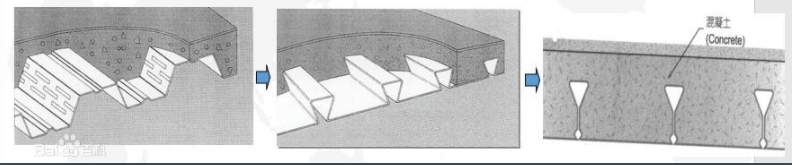

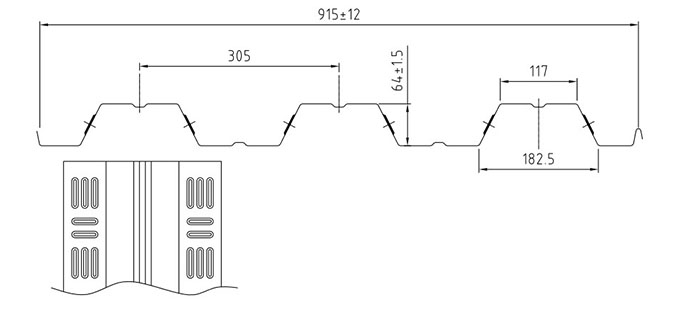

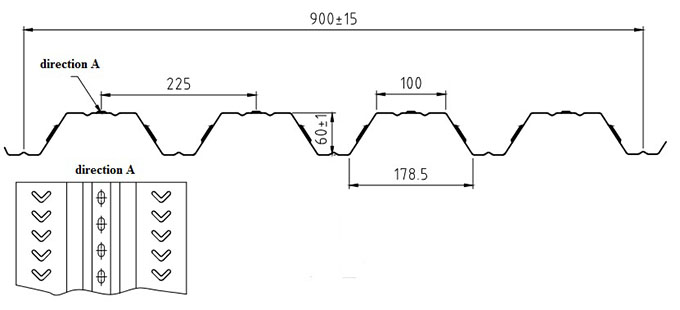

The roll forming process is as follows. When the metal strip passes through several pairs of perforated rollers in turn, the strip is fed forward with the rotation of the rollers and is continuously bent at the same time, to obtain a product with a desired cross-sectional shape. It can be seen that roll forming is a continuous bending forming method. The strip begins to bend and deform at the entrance of the rollers and moves forward at the same time. When it reaches the center section 4 of the roller, the forming in the second pair of rollers ends, passes through the roller, and then enters the third pair of rollers.

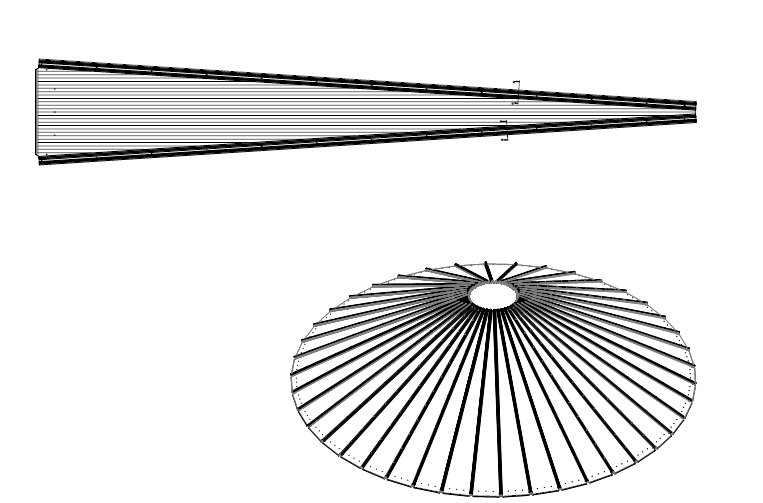

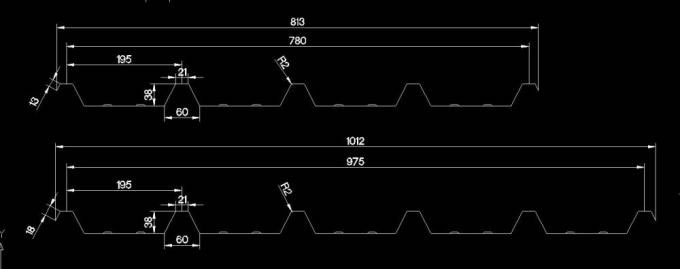

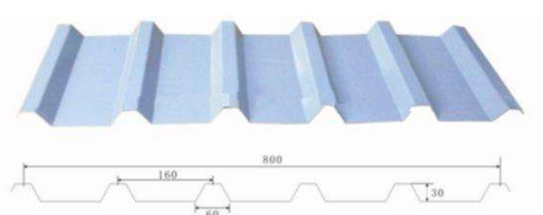

Cold Roll Forming process is a plastic processing method in which the full length of the strip passes through several different holes in sequence, and the parts are gradually bent and deformed. The full cross-sectional shape gradually approaches the cross-sectional shape of the finished product, and finally a product with a full-length uniform cross-section is obtained. The pass is formed by the contours of two or more shaping rolls (also called rollers, rolls) with a certain shape. The shaping rolls may be horizontal or vertical. Pass type is one of the important factors affecting product quality and productivity. The forming roller is installed on the frame, and the forming roller responsible for driving the strip forward is driven by a motor through a transmission system. Generally, only the horizontal roller is the active roller, and the vertical roller is often the passive roller. Each frame is called a forming machine, each forming machine is equipped with two or more forming rollers, and each row of forming units is composed of more than two forming machines.