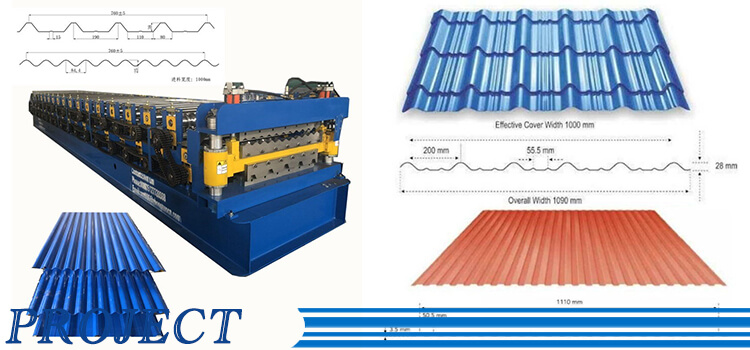

The introduce of Color steel glazed tile

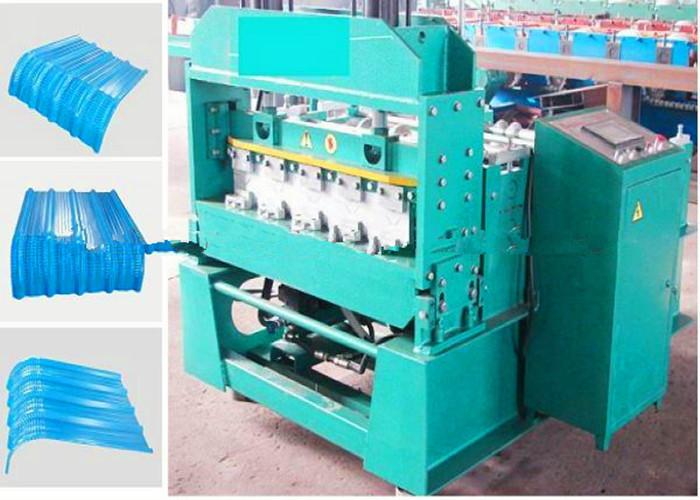

Steel color glazed tile is made from colored level sheet by color steel roll forming machine.Which can be divided into a variety of color plate,But according to categories,It can be divided into the timber roof and wall panels timber.color glazed tile general as roofing sheet,use the steel structure the roof,this is to ensure the appearance of the building, also can extend the life of the building.The house built with steel,The biggest advantage is to save resources.

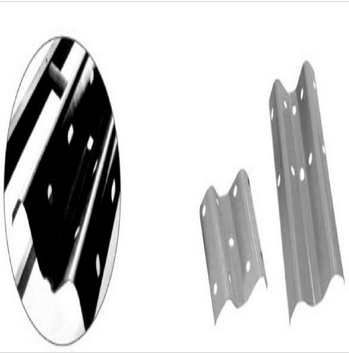

Loadbearing walls are all built with special steel(as C steel,Z steel and so on),then do wall with the composite sheet.The roof is used color glazed tile.

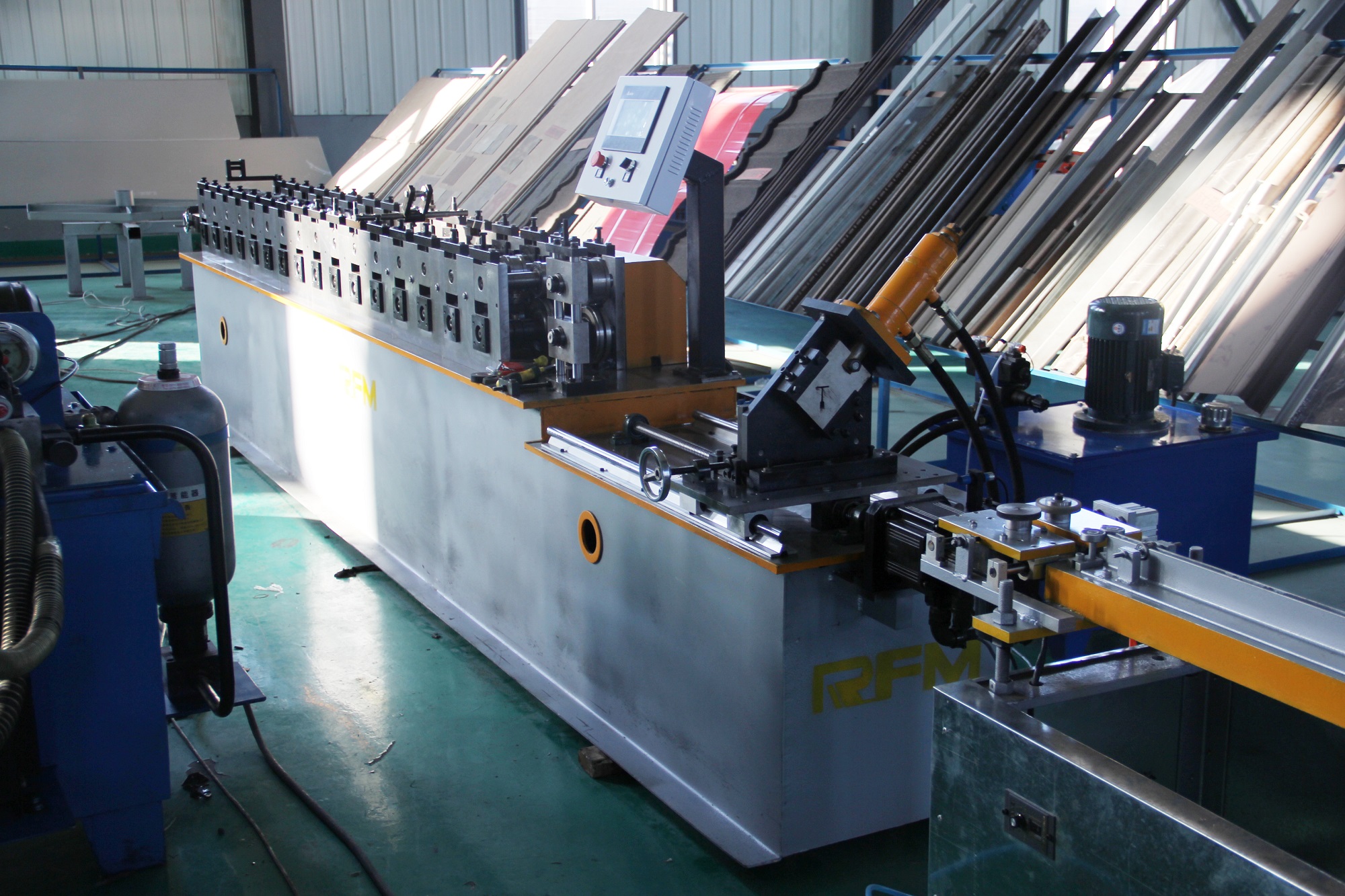

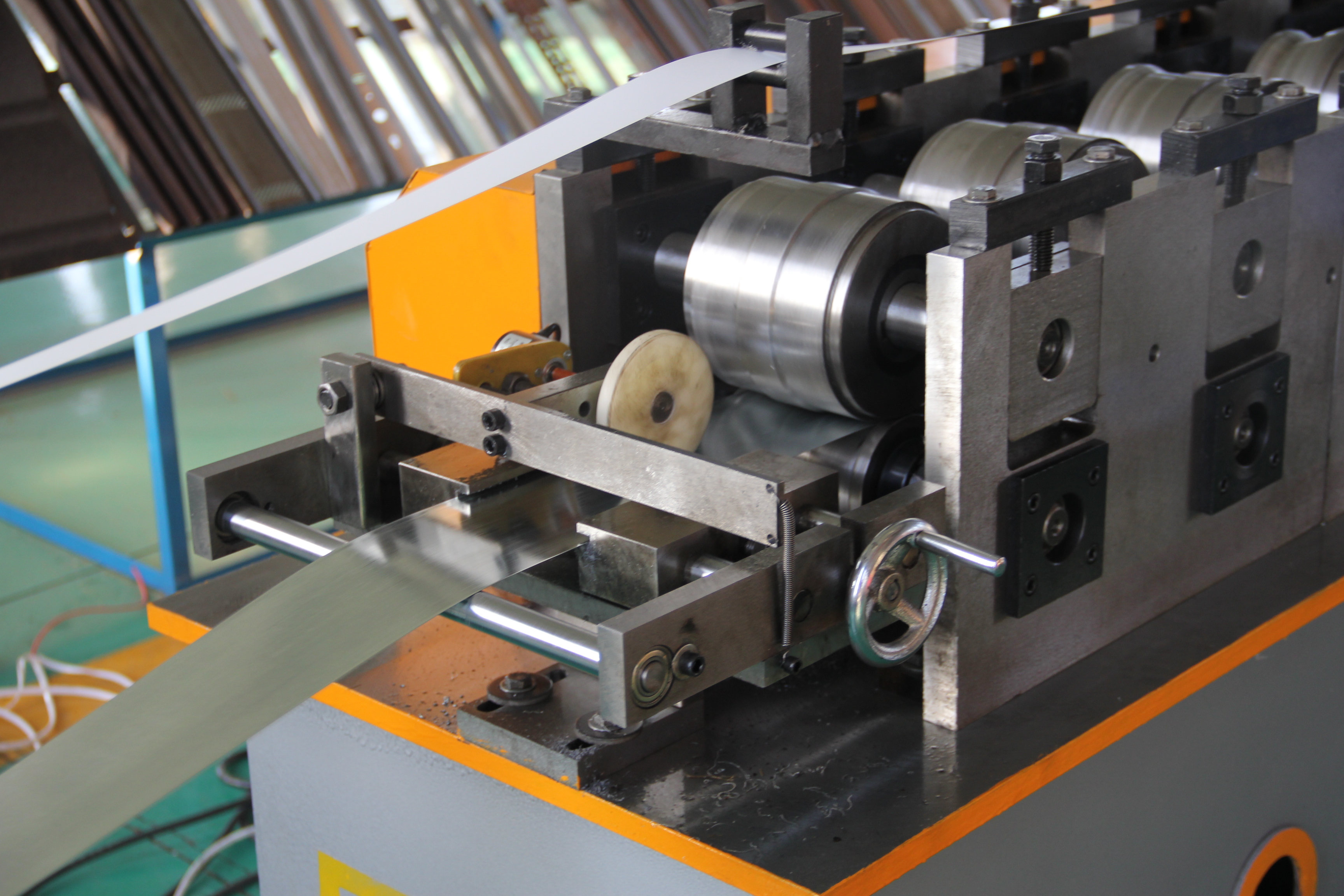

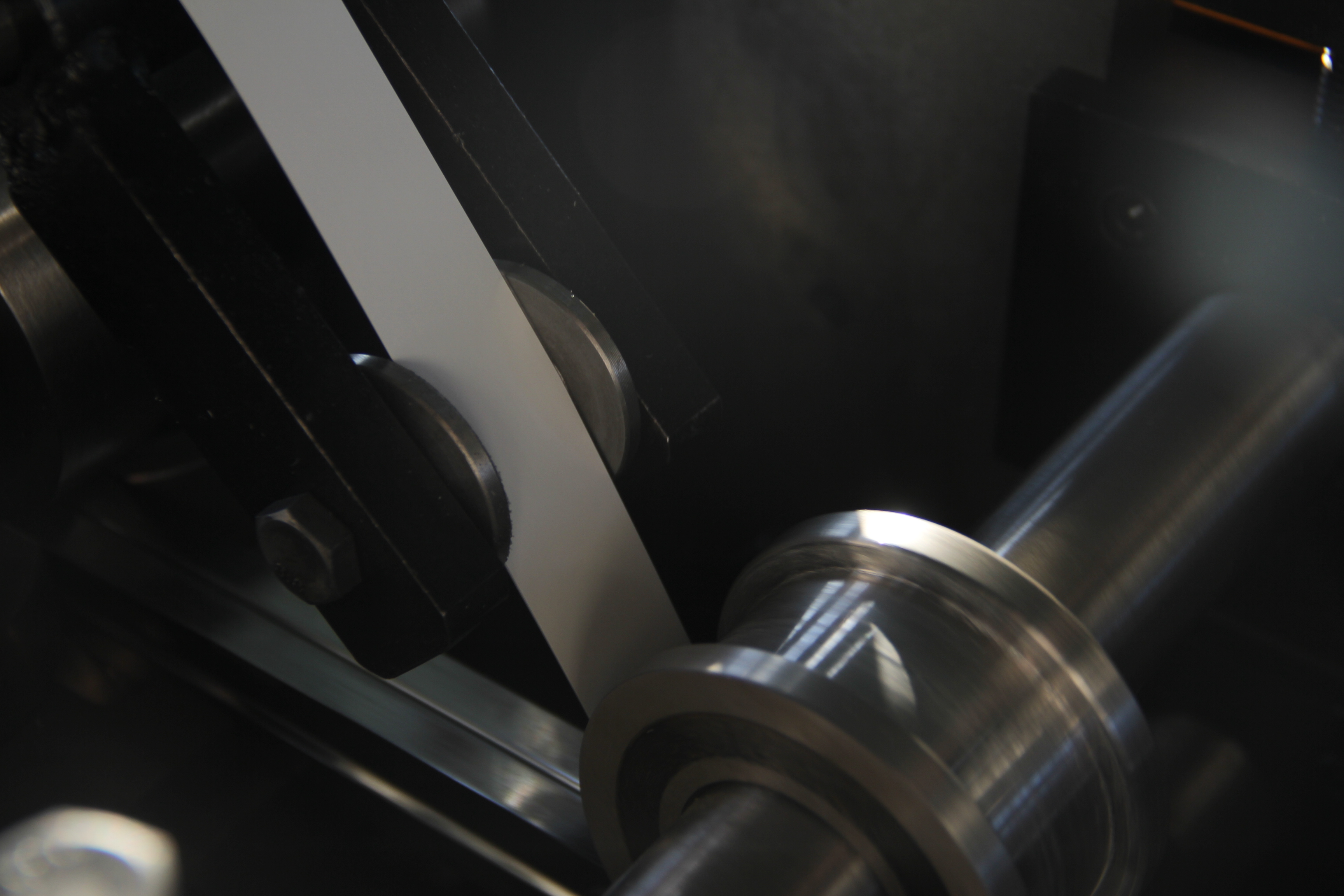

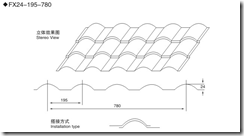

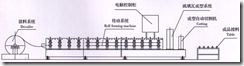

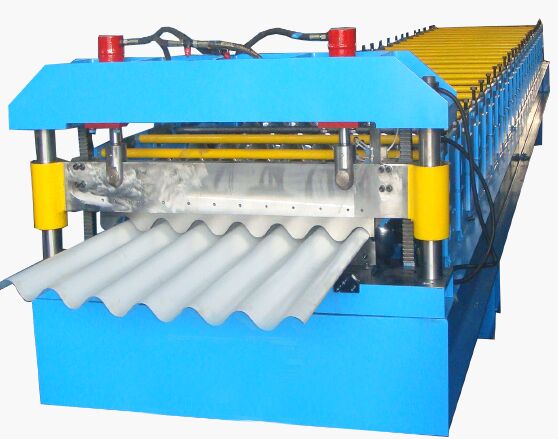

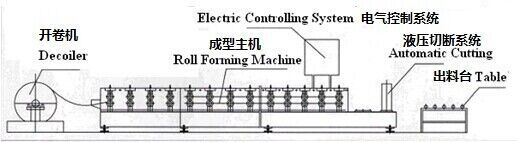

The equipment of the steel color glazed tile is used the H steel make the bottom seat,in the above set up two sides of the support frame,divided into many rows.Each row in the middle have leave some distance,to put pressure type of shaft.The designer according to the shape of the plate,design the corresponding axis.Each shaft and shaft drive with the chain,in addition to the first axis,use the reducer to drive.The gearbox is automatic with PLC control system.You can request to control the length Color glazed tile panels to give the ideal plate