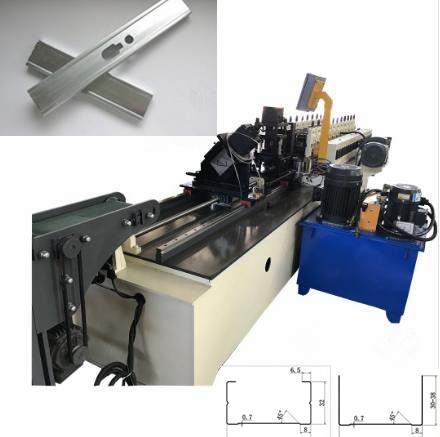

Heavy duty 1.5′ B DECK COMPOSITE DECK ROLL FORMING MACHINE FLOOR DECK ROLL FORMER

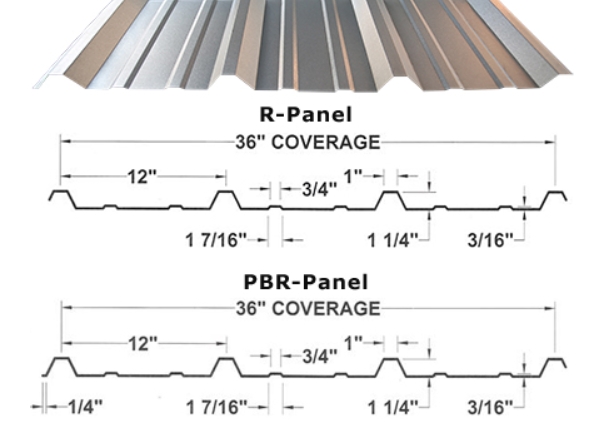

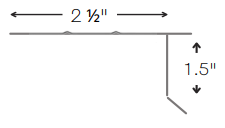

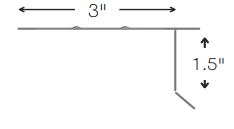

Cangzhou zhongtuo is a leading producer of steel deck roll forming machines. We had experience of making roll forming machine of 1.5′ B deck, 2′ deck and 3′ deck, N deck and so on. B Deck is a conventional metal deck profile in the United States which meets recent North American Specification(ANSI standard). B Deck is usuallly produced using 0.8-1.5mm(Gauge 22, Gauge 20, Gauge 18, Gauge 16) thickness galvanized steel.

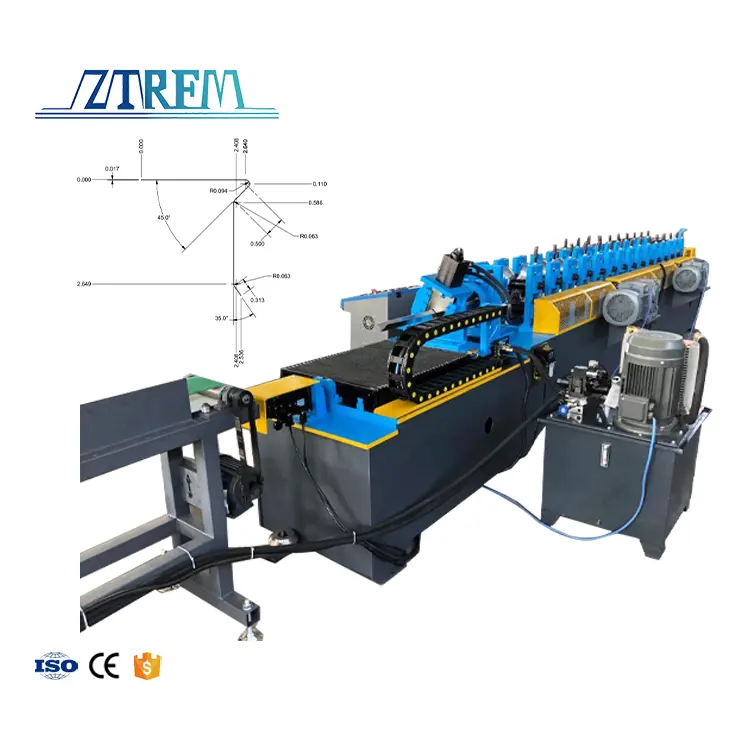

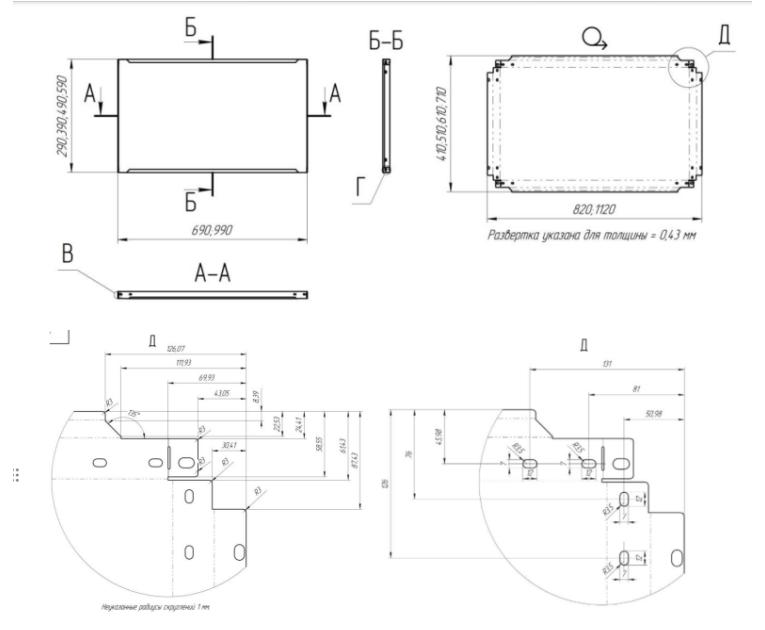

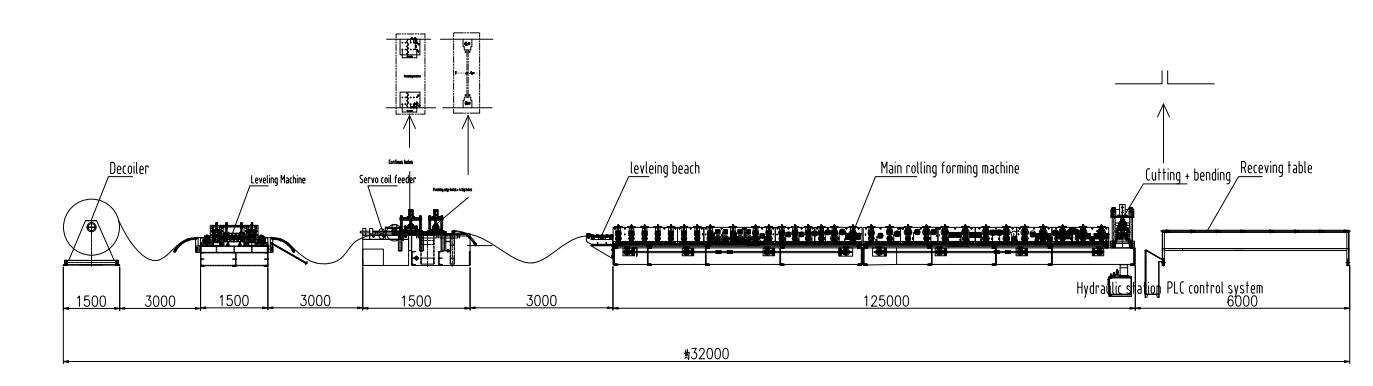

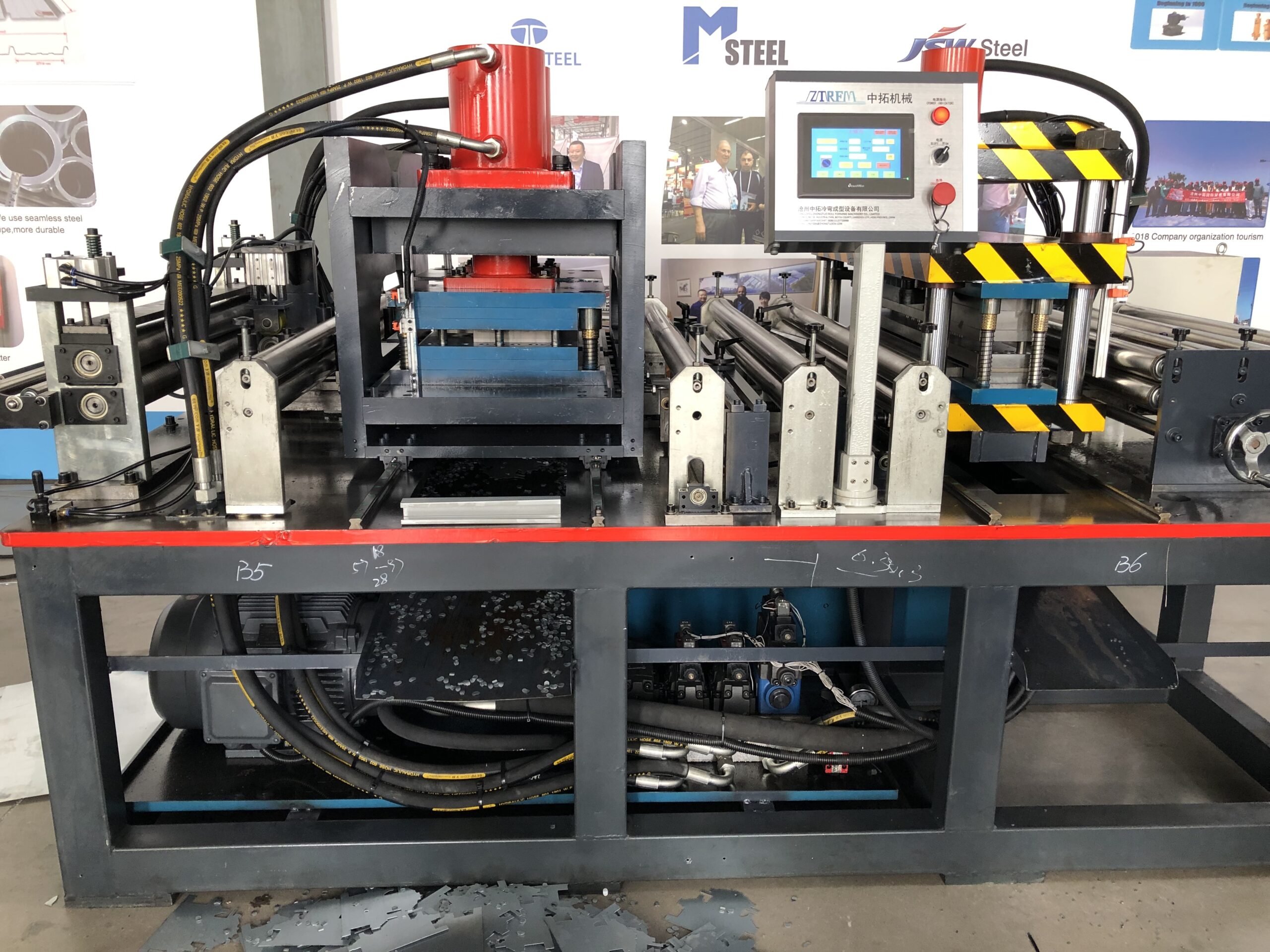

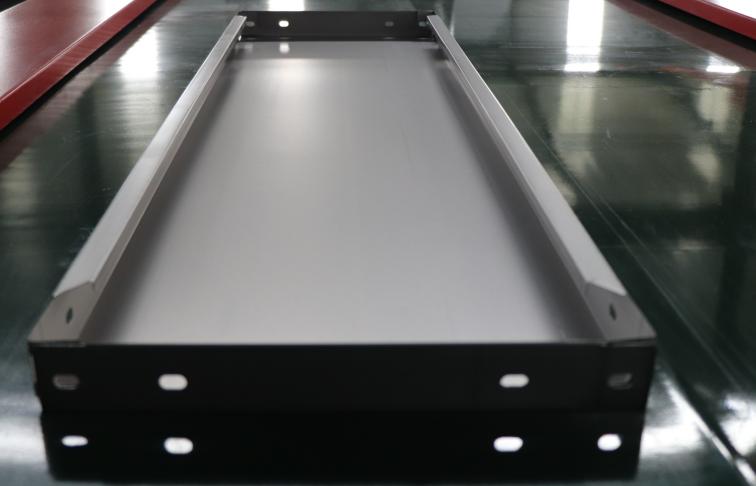

Our roll forming machine uses 28 forming stations to make perfect B Deck profile, if the yield strength of steel material is higher than 345MPa, it will need more forming stations. Our machine body is sturdy and durable. The machine body is about 20 meters long, it can be disassembled into 2 sections for easy transportation and installation. The roll forming part has two 22KW motors, Siemens brand control system, powerful during production. Shafts φ95mm, forming rollers GCr15 chromed plated surface is bright and not easy to rust, and will not cause scratches on the surface of galvanized steel. The exquisite processing technology makes the machine more smooth in operation and it has a longer service life. The profile produced by our roll forming machine is straight and horizontal, with high accuracy in flatness and distortion, and the length accuracy can be controlled within plus or minus 1mm.

|

Galvanized Steel Metal Deck Making 1.5B Decking roll forming machine

|

||||

|

Size of main part

|

about 15000 х 1850 х 1500 mm

|

|||

|

Weight of main part

|

about 15.5 t

|

|||

|

Processing material

|

galvanized coils yield strength till 550 Mpa

|

|||

|

Material thickness

|

0.8-1.5 mm

|

|||

|

Input material width

|

1220mm

|

|||

|

Effective width after forming

|

914mm

|

|||

|

Voltage

|

480 v 60 hz 3 phase or as request

|

|||

|

Frame

|

400 H beam steel welded

|

|||

|

Roller fixer

|

Middle plate (thickness 20mm)

|

|||

|

Drive mode

|

2 inches double chain with chain tensors(gearbox type optional)

|

|||

|

Material of rollers

|

Gcr15 quenching treat HRC58-60

|

|||

|

Material of shafts

|

45# steel precision-machined

|

|||

|

Diameter of shafts

|

φ 95 mm

|

|||

|

Number of rollers

|

about 28 rollers

|

|||

|

Drive motor power

|

18.5 kw x 2 sets

|

|||

|

Forming speed

|

0-15 m per minute

|

|||

5 tons ,7 tons,8 tons,10 tons,12 tons,15 tons optional(or other customized)Click picture for details.

- With supporting rollers, to feed material more smoothly, protect material.

2. The front rollers are with two gears outside, to make the up shaft run from passively to actively, with more power to feeding material, and run more faster to prevent stockpile. (The advantage of that: You can see that there are 2 gears outside the structure which is on the shafts in the first station. The gears connect the upper shaft and down one, the gear can drive the shaft moving actively. Normally, the chains only connect the shaft in the down layer, the upper shafts are moving passively. But now we adopt the gear in the first three stations, both the down layer shaft and upper layer shaft are moving actively, it can ensure the metal sheet feed into forming system in the same speed and same level.)

Automatic stacker

- Auto stackerfor reception of the cut profiles: included, allows free unloading of each cut profile and automatic placement on the stack of previously made products, total unit length after assembly – at least 8 meters;

- Stacking principle: the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet;

- Unloading of the finished products (moving of the stack of finished products from the production line): mechanic, it will be possible to pick the stack using a fork-lift or in a similar manner (fork-lift will be provided by customer).

- Take the sheet by air compressor, 5.5KW( provide by customer)

- Aircylinder swing arm size: 40mmx80mm

- Transmission power:3kw AC motor

- Stacker length in 8m(26 feet)

- Drive of transmission by 1.0inch double line chain

- Transmission roller: ASTM1045 with chrome, diameter of roller is in 80mm

- Carrying capacity: maximal 5000Kgs

- Length of capacity: 500-6000mm

The maximal stacker height: 300mm