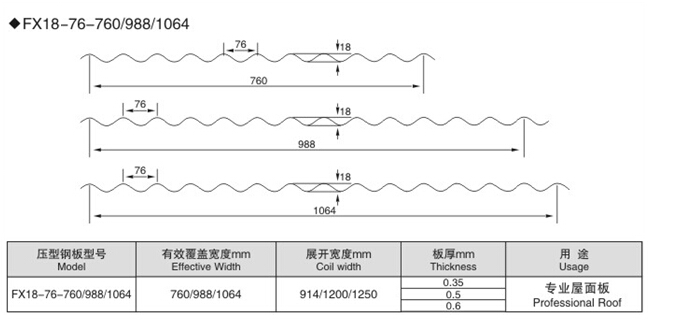

Corrugated Plate Roll Forming Machine18-76-760/988/1064

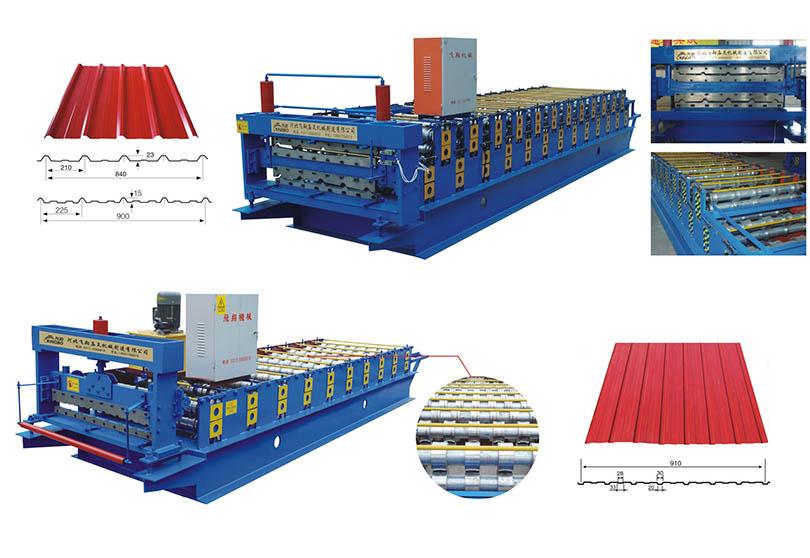

Corrugated Plate Roll Forming Machine is mainly including entry beach, main roll forming machine system, shearing mechanism, hydraulic station, electric control system.

18-76-760/988/1064style corrugated sheet roll forming machine is mainly including entry beach, main roll forming machine system, shearing mechanism, hydraulic station, electric control system. The producing is applying for roof of variety of workshop of factory, housing, warehouse, and market. It is nice shape and outstanding durability.

Craft process: uncoil feeding molding cutting product

Corrugated Plate Roll Forming Machine18-76-760/988/1064

Main component

Uncoiling system

Usage: to support the membrane to facilitate stretching, automatic open-book binder.

Diameter:450-550mm

Uncoiling width:1250mm

oading capacity:5000kgl

Entry beach:

usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Main roll forming machine:Feature : Ensure stability , precision and lifetime

Length of the main part: about 7.5*1.45*1.5m

Weight of main part:5T

Voltage: customer can choose

Frame: 4560# H steel

Transmission: Chain

Material of shape: 45# steel adjustable, diameter 80mm, sophisticated processing.

Wheel Material: GCR15, after quenching, and chrome-plated wheels through a gap

Material of rollers:

Strength bolts

Number of rollers:15 rollers

Motor power: 5.5KW

Forming speed:

Shearing Mechanism

Advantage: ensure stable, precision and high cutting speed.

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products

Material of blades: Gcr12 quenched

Cutting system: advanced hydraulic system, automatic cutting, no waste coil, highly safety.

Cutting error:±2mm

We measuring product use PLC and code, this style is higher than photoelectric measurement.component: it including

Hydraulic station:

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump,four hydraulic pipes.and two sets of electromagnetism valves.

Hydraulic oil:40#hydraulic power:3kw

Electric Control System

1ã€5.7 inch of Panasonic touch screen from Japan to ensure high speed with stability, precision and lifetime.

2ã€Panasonic of PLC and converter.

3ã€Automatic length

4ã€Automatic count

Automatic stop the cutting, control length

5ã€match with moveable switch, fuse link, radiator, transformer and RCD.

Counter:

One counter gauges length, pulses, and decides length.

Omron encoder for length measurement.

Products receiving tables:

6*40mm jointing

pulleysize:

3*0.9*0.6m

Accessories:

1ã€Easy damaged parts:conk 2pcs, fuse-link 4 pcs.

2ã€Rubber mat 1 pcs

3ã€Bolt spanner 1 pcs

Payment termPrice: (including duty)

The way of the payment: Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit.

Warranty:

1ã€One year, and we will provide the technical support for the whole life

2ã€Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

3ã€Need one technician

4ã€Training time: one week (contains the time of installation and adjustment)