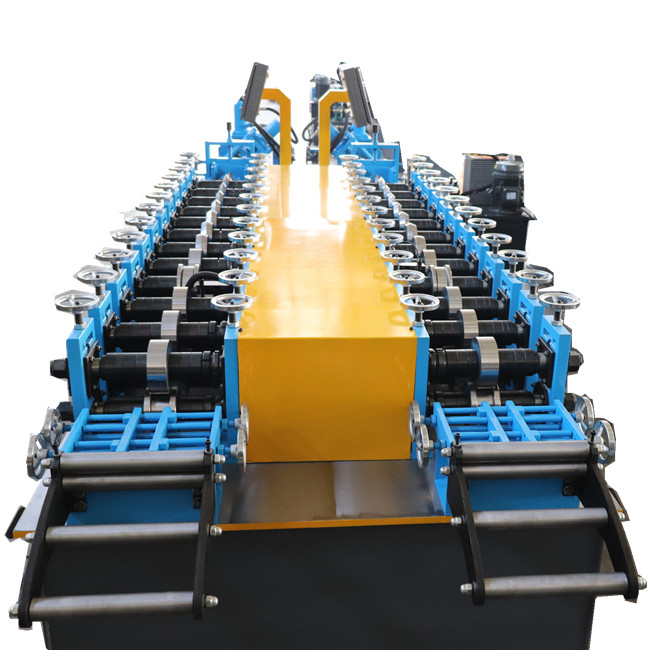

DOUBLE LINE STUD AND TRACK ROLL FORMING MACHINE

A double line stud and track roll forming machine is designed to produce two or more profiles like stud and track in one machine , save cost and space. And the machine can produce the two profiles at the same time.

A double line stud and track roll forming machine

A double line stud and track roll forming machine is designed based on the idea of one machine for two or more types profiles like stud and track to produce on the same machine. Those two profiles can work at the same time. Here are some examples:

A double line stud and track roll forming machine

Main Roll Former of A double line stud and track roll forming machine

Size: 4800х1800х1400mm

Weight t: about 3.2tons

Voltage:Customize as clients needs.

Roller fixer : Guide column type

Frame : wall-panel welded

Memorial arch frame type

Frame thickness:25mm

Drive mode: gear drive

Material of rollers: GCr12MoV

Material of shafts: 40Cr steel with tempering

Diameter of shafts: φ60mm

Number of rollers for stud :11 rollers

Number of rollers for C channel :14 rollers

Main power: 5.5 kw

Cycloidal planetary gear speed reducer

Punching holes

The molds are changeable. We offer holes molds related.

Servo tracking shearing system to allow non stop cutting and fast working

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

One more cutting blade is offered to change to fix those different drawing profiles.

Hydraulic Station

Hydraulic motor Power: 5.5kw

Hydraulic oil: 46#

Components: The system includes a hydraulic tank, a hydraulic oil pump, and two hydraulic pipes. And three sets: one punching hole; one for printing words and one for cutting.

Electric system:

- PLC, transducer, and touch panel from Delta Taiwan ,ensuring high speed , stability, precision, and serivice time.

- Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

The advantages of Combined stud and track rolling forming machine:

- Save space. It takes less space then 2 machines.

- Save worker. one worker can watch two lines.

- High work efficiency. 40mpm allows it to work more efficiently.

- Save cost. It is more economic than two seperate machines.

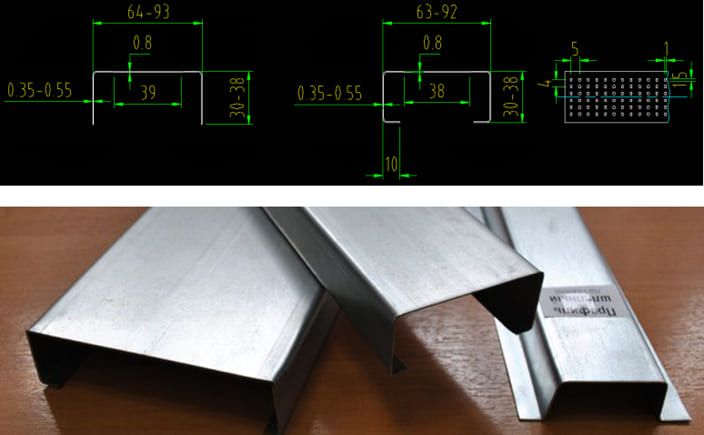

The machine can be customized as the C and U and other profiles and sizes you need to make, just feel free to contact us if you need any machine.