Fast Speed 20m/Min-Strut Channel Roll Forming Machine Automatic Solar Panel Framing Machine Slot Strut Channel Machine

Description of Strut Channel Roll Forming Machine

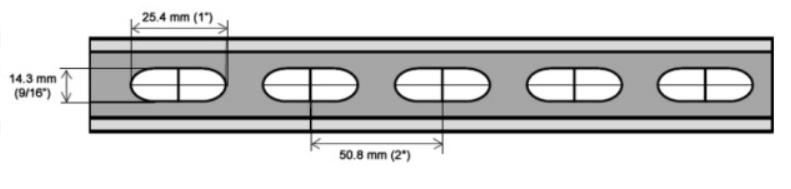

For cutting, we offer options such as saw cutting and hydraulic cutting, tailored to your specifications. Our machines also include a punching system; some clients prefer hydraulic punching, others opt for punching presses, while some choose to punch holes after the C channel has been formed using a separate machine, thereby improving production efficiency.

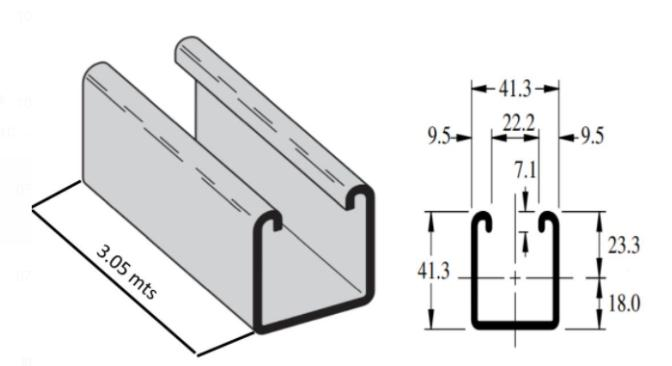

The operation of our machines is user-friendly and straightforward. We primarily utilize pre-galvanized steel, hot-rolled and cold-rolled steel, along with stainless steel, with material thicknesses ranging from 1.5 mm to 2.5 mm. The most frequently requested strut channel profile sizes include 41×21, 41×41, 41×62, and 41×82.

For more information about our machines, please don’t hesitate to reach out.

We are a specialized manufacturer of C channels, unistrut, solar panel stands, and seismic stabilizer stand roll forming machines. Our equipment is capable of producing C channels in various sizes, with flange adjustments available in both manual and automatic modes to accommodate customer needs.

Purpose of the Equipment:

– Mainly intended for producing strut channels for solar photovoltaic mounting systems.

– These channels play a crucial role in installing, supporting, and connecting lightweight structural loads in construction projects.

Product Specifications:

– Designed to produce a wide variety of strut channel specifications and types, including:

– Solid channels

– Slotted channels

– Half-slotted channels

– Long-slotted channels

– Perforated channels

– Combinations of perforated and slotted channels

Machine Features:

– High precision and durability ensure the quality and stability of the strut channels produced.

– The user-friendly design lowers the skill level required for operators.

Profile Drawing:

Typical Applications:

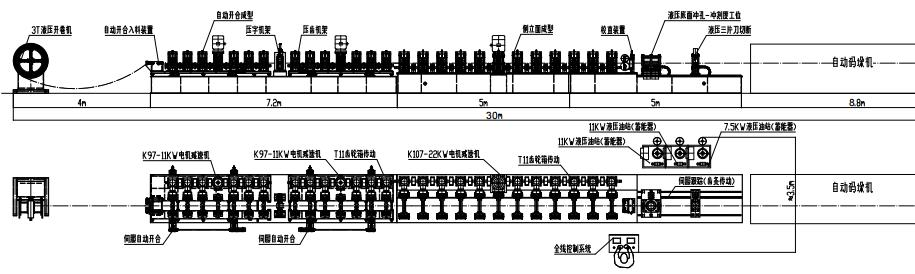

Strut Channel Roll Forming Machine Working Flow:

Automatic feeder(3T) → leveling → punching → roll forming machine → re-forming → saw cutting → output

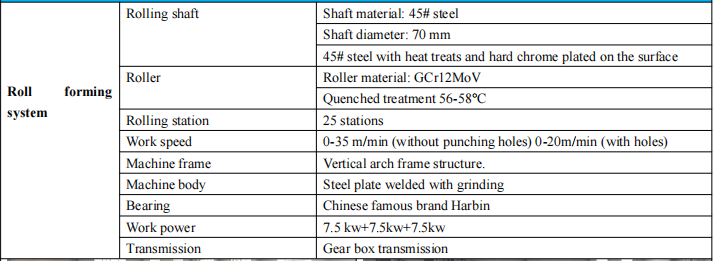

The Technical Specifications Of the strut channel Roll Forming Machine Rolling Forming Machine:

|

Strut Channel Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 1-2 mm | ||

| Decoiler | Roller station | 25 station | The standard one to match the production line |

| upper 3 + down 4 to level the coil. | |||

| Loading capacity | 3 Tons | ||

| Coil inner diameter | 450-600 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 70 mm | ||

| Roller material | GCr12MoV | ||

| Rolling station | 18 stations | ||

| Work speed | 0-35 m/min (without punching holes) 0-20m/min (with holes) | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Chinese famous brand Harbin | Famous brand of Harbin | |

| Work power | 7.5 kw+7.5kw+7.5kw | ||

| Transmission | Gear box transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

|

| Decoiler, we can change to hydraulic one if you need. | |||

End other Product:

More detailed pictures of the machine: