Heavy duty Automatic CZ purlin machine User Friendly CZ Purlin Machine for Simple Operation and Maintenance

Description of CZ Purlin Roll Forming Machine

Cangzhou Zhongtuo offers a variety of purlin and girts forming machines, designed to accommodate profiles ranging from 100mm to 400mm in both Z and C shapes. These machines provide options for cutting to length and can be configured as either punched or unpunched.

CZ purlin machine Configuration :

- Material thickness :1-3.5 mm

- C purlin : 80 – 350mm

- Z purlin: 120 – 350mm

- Material yield strength: 235/345 Mpa, Q420

- Sizes changing automatically

- C and Z purlin changed automatically

- Servo motor drive

- Separate cabinet PLC

- Panasonic PLC and Schneider electric part

Machine safety cover include roll forming part and punching part,it has a safety switch and cannot be opened while the machine is running.

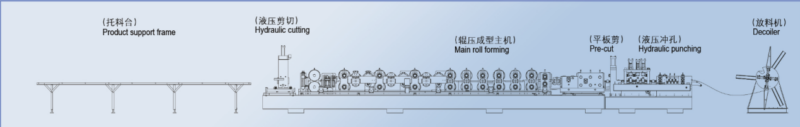

Working flow:

Uncoiling → Feeding material into machine →Leveling → punching and pre-shearing →roll forming →Products receiving table

Feeding and leveling part

There is an electric button here, which can automatically adjust the feeding width

Leveling rollers: 3 up 4 down

Roller material: Cr15

Roller diameter: 75mm

Side rollers: 2 sets (big one) shafts is also bigger and stronger one.

Feeding width adjustment: automatic by button

Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate

Punching and pre shearing part

Punching unit with hydraulic system;

Punching mold:Gcr12 quenched treatment

Station 1: Bottom center holes punching

Station 2: Bottom double side holes punching

Station 3: Bottom double side holes punching

Station 4: Bottom double side holes punching

Station 5: Pre-Hydraulic shearing

Cr12 CNC processing heat treatment to

HRC: 58-60 ,finish turning

Roller stations :22 rows

Diameter of shafts:φ90/φ75 solid

Material of shafts:

40 Cr CNC processing

HRC28-32 ,finish turning and electroplate

Forming speed: max 37m/min

Voltage: 380V/50HZ/3P (as requested)

Transmission way :

Double chains + shaft end support

Servo motor power: 42 Kw

Sizes changing: by Laptop / Electric button

C and Z purling change : By manual

Hydraulic station