Heavy Gauge Metal Studs and Tracks Roll Forming Machine Steel Stud & Track Roll Former Steel Framing

Stud And Track Roll Forming Machine

The machine is designed to accommodate web sizes ranging from 3″ to 6″ (75-160mm), categorized into four sections: 3″-3 5/8″, 3 5/8″-4″, 4″-5.5″, and 5.5″-6″. Each section is equipped with corresponding chamfer-cut and notch-cut tooling, allowing for quick and seamless punch tool exchanges to produce various steel profile sizes. It supports profile widths of 3″, 3.5″, 3.625″, 4″, 5.5″, and 6″, with flange options of 1 1/4″, 1 5/8″, and 2″. The machine handles galvanized and H.R. steel in thicknesses from 22 to 16 gauge, with a maximum yield strength of 80 ksi at 1.6 mm (16 gauge) thickness.

Advantages of the Stud and Track Roll Forming Machine

- Fully Automatic Size Adjustment: The PLC system allows for fully automated adjustments of the roller distance, making size changes quick and efficient.

- Durable and Long-Lasting: The machine is equipped with an oil-drop system that cools the rollers during operation, extending their lifespan.

- Fast Production Speed: With gearbox transmission and dual-motor main transmission systems, the machine can operate at speeds ranging from 25 to 45 meters per minute.

- Customizable Profiles: The machine can easily switch between different profiles by adjusting the spacers or using a cassette-type change system, saving both time and costs.

- High-Quality Shearing: The servo motor ensures clean, precise cuts with no burrs, improving the overall quality of the final product.

- Energy-Efficient Non-Stop Operation: The energy tank system allows for continuous punching and shearing, making the production process smoother and more energy-efficient.

Details Information of Profile drawing:

Metal profile stud rolling forming machine is designed to make the metal profiles in batch fully automatically. Metal profiles are precision-engineered, high-quality steel sections that are used to form the metal substructure of the Drywall or ceiling Systems. All metal sections produced from high-grade hot dip galvanized steel coils with the cold rolled forming process by the rolling forming machine. Here we will take some random drawing to show you how the metal profile rolling forming machine is designed.

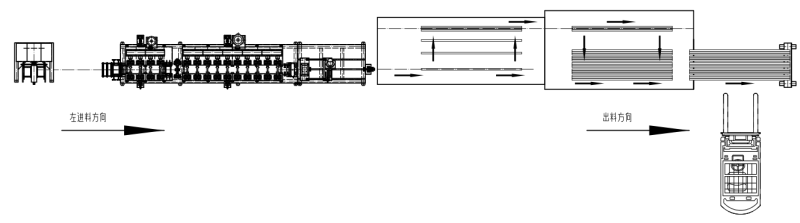

Machine Work Flow :

Application:

The Technical Specifications Of The Stud And Track Roll Forming Machine :

|

The Stud And Track Roll Forming Machine |

||

| 1.Formed Material | Galvanized steel, Aluzinc | Thickness:0.2-0.8mm |

| 2.Decoiler | Hydraulic automatic decoiler | Hydraulic expansion, can save labor, easy and fast operation. |

| 3.Main body | Roller station | 14 rows(As your requirement) |

| Diameter of shaft | 60 mm solid shaft | |

| Material of rollers | Cr12, with heat treatment HRC 58-60 | |

| Machine body frame | Iron cast molding frame | |

| Drive | By gearbox, as per customer’s requirement | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Production line speed | 0-40m/min | |

| 4.Cutter | Automatic | Flying cutting. When the machine cutting it will not stop,GB-Cr12 |

| 5.Power | Motor Power | 11KW |

| Hydraulic system power | 7.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-40m/min | Speed is adjustable according to customer’s request |

More pictures of the machine: