High Quality Australian Style Roller Shutter Door Roll Forming Machine

Feature of Australian Shutter Door Roll Forming Machine

Australian steel roller doors are designed for easy installation, quiet operation, and manual lifting. They come in attractive colors with a sleek, horizontally embossed finish. Roll Doors Australia products are known for their enhanced durability and straightforward installation process, which speeds up construction and shortens project timelines. Made from stainless steel, these rolling shutters not only create an appealing aesthetic but also ensure effective ventilation. Additionally, they offer robust security, providing strong isolation and anti-theft protection.

Roller Material: 45# steel with hard chrome plating on the surface.

Shaft Material: Tempered 45# steel.

Shaft Diameter: φ70mm.

Roller Count: 24 rollers.

Design: Separate molding ensures a precise, attractive profile.

Main Power: 11 kW (cycloidal planetary gear speed reducer).

Advantages of Our Australian-Style Roller Shutter Garage Door Roll Forming Machine:

– Separate molding roll forming ensures each wave has a smooth finish without surface scratches.

– Pre-shearing includes 4 additional roller stations for edge trimming, resulting in a neater lock edge.

– Waste coil collector and slitter allow the machine to accommodate wider coils if needed.

– Equipped with two-pillar pole shearing, providing both strength and an attractive design.

Differences from Traditional Roll-Up Doors:

– The Australian-style door panel is a single, continuous piece, unlike traditional models where multiple sections are connected in series.

– A unique spring system keeps the door balanced in any position, enhancing stability and ease of use.

– Muffler belts on both sides of the door panel ensure quiet, smooth operation.

– We provide online exhibition options, allowing customers to explore our products and gain a broader understanding of our offerings conveniently. ZTRFM Machinery guarantees high-quality, functional profiles.

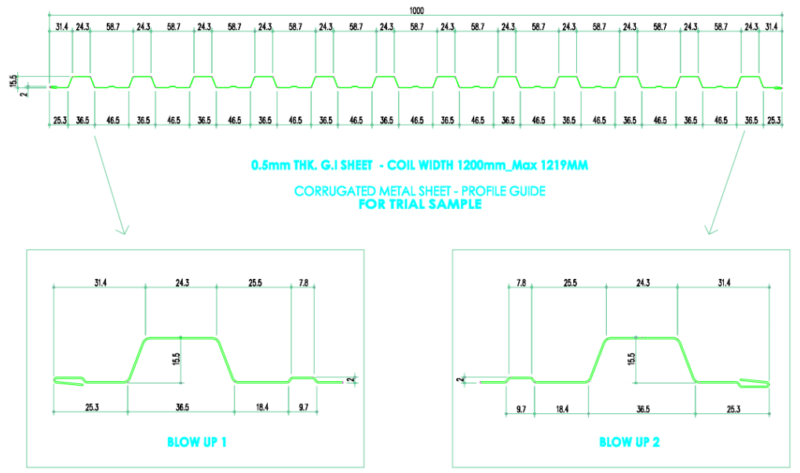

Profile drawing:

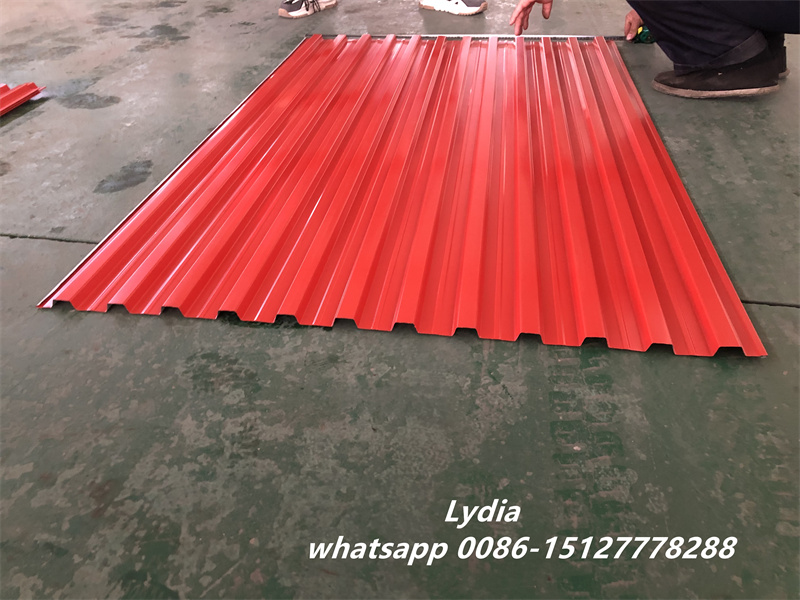

Finished Product Pictures:

Application pictures of rolling shutter door structures:

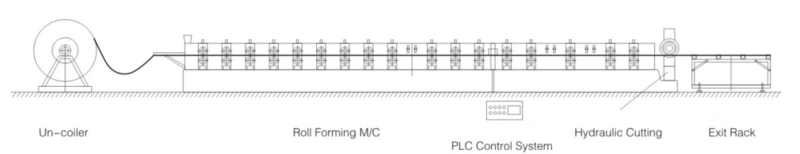

Flow Chart:

Why Choose us:

– Over a decade of experience in manufacturing high-quality equipment for cold-formed steel structures.

– Competitive pricing paired with exceptional quality.

– One-year warranty at no additional cost.

– Prompt after-sales support to address any concerns.

– Customization options available based on client specifications.

– Designed for ease of operation and maintenance.

The Technical Specifications Of Australian Rolling Shutter Door Machine:

Check out more detailed features for further information.

| Series | Details | Parameter |

|

Product sheet |

Raw material | PPGI & GI |

| Material thickness | 0.6-0.8mm | |

| Sheet cutting length | Adjustable | |

|

Decoiler |

Work type: Passive type, Expand and shrink manually | |

| Structure:Steel channel welded for the basic frame | ||

| Usage:To support the coil and make the uncoiling, need the forklift or overhead crane to carry the coil on decoiler | ||

| Loading capacity: 5 tons, Coil width: 1250mm | ||

| Inner diameter: 450-550mm (manual adjustment) | ||

| Manual brake system, with big hand driving wheel, easy to operate | ||

|

Rolling shaft |

Shaft material:45# STEEL | |

| Shaft type: solid shaft | ||

| Shaft diameter: 70 mm | ||

| Roll forming machine | Tempering treatment to prevent deformed and improve hardness | |

|

Roller |

45# steel | |

| 0.03mm Chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

| Rolling station | 24 rolling stations | |

| Middle wall plate thickness | 18mm thickness | |

| Work speed | 0-20 m/min | |

| Machine structure | Carbon steel welded structure | |

| Machine basic frame | 300# H steel welded | |

| Anti rusty treatment after welding | ||

| Work power | 5.5 kw | |

| Rolling spacer | Anti rusty treatment | |

| Steel bar | Anti rusty treatment | |

| Transmission | By Chains with cover | |

| Control system | Frequency brand | Delta (original) |

| PLC brand | Delta (original) | |

|

Hydraulic system |

Work type | Hydraulic cutting |

| Driving method | By pillar type Cylinder | |

| Hydraulic motor power | 5.5 kw | |

| Cutter material | GB-Cr12 | |

| Cutting length tolerance | ±1mm/3m | |

| Cutting feature | Steady and safe working condition | |

More Pictures Of The Machine: