L Trim And J Trim Roll Forming Machines produce L and J Trim panels in great quantity and quality. But why should you buy one, and what do they even do?

Description of L-Track Roll Forming Machine

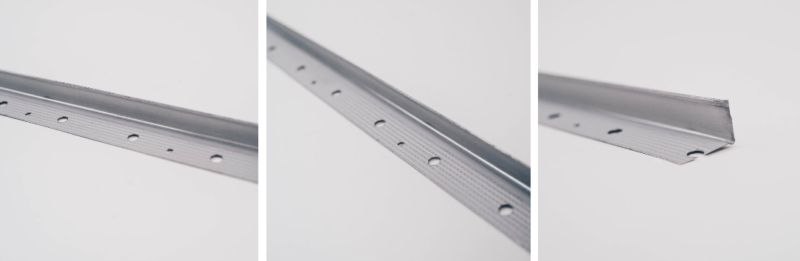

L-track is a tool whose value often goes unrecognized until it becomes essential. Once you’ve experienced its utility, you’ll discover various methods to utilize L-track as a flatbed driver. This light-gauge galvanized steel utility angle is versatile and used in numerous applications, including column framing and bulkheads. We offer a wide range of L-track systems, complete with hooks, tacks, fittings, and other accessories, because we understand their significance.

The universal light-duty steel L-track fitting is compatible with any style of aluminum load track. You can easily attach almost any item to the aluminum tracker using these fittings. Additionally, you can reposition components along the track by simply drilling a hole in the desired part.

For light loads that don’t require traditional winches and tie-downs, L-track is the optimal solution. It is user-friendly, straightforward to install, and incredibly efficient. If you’re in the market for L-track solutions, we likely have exactly what you need. All our L-track stud fitting products meet the same high standards that characterize our other offerings.

How Does the Machine Work?

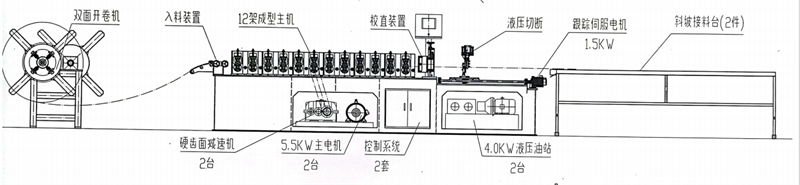

Similar to other roll forming machines, this equipment begins by feeding sheet metal through a designated feeding device from the decoiler located at the back of the machine. Once the metal enters, it moves through the roll forming mill, where a series of fixed rollers shape it into either an L or J profile. After forming, the material is cut using a hydraulic post cutter, which then transfers the finished product to the hydraulic station and exit rack, where the final panel is ready.

The entire process is managed by advanced control systems that offer both reliability and cutting-edge technology. Utilizing a roll forming machine provides several advantages:

– High strength

– Large working load capacity

– Consistent quality and quantity

– No cutting deformation

– Excellent uniformity

This machine can be customized to meet your specific requirements, making it versatile and tailored to each customer’s needs.

Why Should I Buy One?

As labor costs continue to rise and machinery advances, the appeal of automated, high-quality equipment for performing routine tasks becomes increasingly compelling. If you have any doubts, we can assure you that our machines are as rewarding as they are dependable. Our machines can accomplish tasks that would take hours of manual labor in just minutes, significantly boosting your profitability.

L and J trim machines are constantly improving and becoming more economical. For any savvy business owner, not investing in such technology would be a missed opportunity. We are a trusted brand that has been thriving since 2009, serving thousands of satisfied customers. Our machines are crafted with precision and care, and they come with a one-year warranty on both parts and labor. So why wait? Contact us today to get yours!

Features of L trim roll forming machine :

Here’s a concise overview of how an L flashing roll forming machine operates:

Material Feeding: The roll forming process begins with a coil or sheet of metal, typically steel or aluminum, being fed into the machine.

Roll Forming: The metal travels through a series of rollers that progressively shape it into the desired L profile. These rollers are specifically engineered to achieve the required dimensions and angles of the L flashing.

Cutting: Once the metal is shaped, a cutting mechanism trims the flashing to the specified length. Various cutting methods may be employed, including shearing, flying cutoff, or rotary cutoff, depending on the machine’s configuration.

Stacking or Coiling: After cutting, the finished L flashings are either stacked or coiled for subsequent processing or packaging.

L flashing roll forming machines are generally customizable, allowing for the production of flashings in different sizes, materials, and profiles to meet the unique requirements of construction projects. They ensure high precision, efficiency, and consistency in manufacturing, making them essential tools for metal flashing production in the construction sector. The selection of materials, thicknesses, and additional features can vary based on the specific demands of a project or the preferences of the manufacturer.

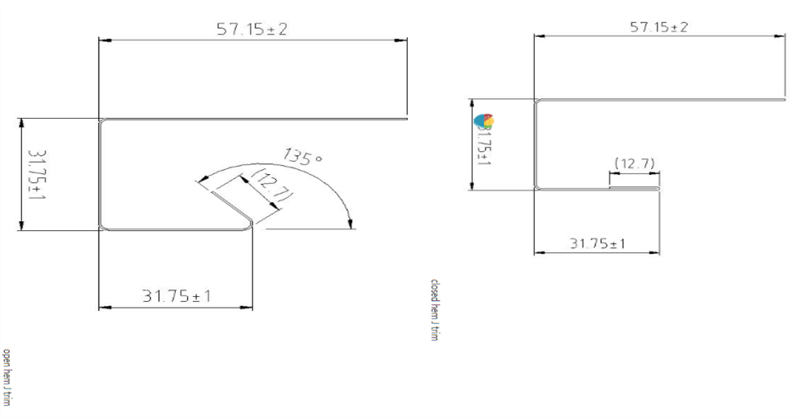

Profile Drawing :

The L Trim And J Trim Roll Forming Machine working flow:

The Technical Specifications Of The L Trim And J Trim Roll Forming Machine:

| J Trim profile rolling forming machine | ||

| 1.Material of coil | Material Thickness | 0.3-0.8mm galvanized sheet full hard 85-95, G550, PPGI |

| 2.Forming system | Rolling Speed | 0-10 m/min( without the cutting time) |

| 3.Main body

|

Roller Stations | About 16-18 stations |

| Roller Material | 45# Steel with quenching 60mm shaft | |

| Maim Motor Power | 5.5 kw | |

| Hydraulic cutting Power | 4 kw | |

| Bearing | Rubber sealing bearing | |

| Material Of Cutting | CR12 with quench treatment | |

| Hardness | HRB 85-95 | |

| Tolerance | +-1.5mm | |

| 4.Cutter | Cutting way | Stop cutting |

| 5.Voltage | Electric Source | 380V 50Hz 3Phase

Also can satisfy Customer’s require |

| 6.Control system | Control System | PLC Delta |

| Inverter | Delta | |

| Weight | About 2.5 tons | |

| Way Of Drive | 1 inch single chain | |

| Size of machine | Length 7500mm* Width 800mm* Height 500m | |

| MOTOR | Under the frame of the machine | |

More pictures of the machine: