Locked Pipe Roll Forming Machine Galvanized Steel Roll Forming Line For Round Pipe

Main features of the pipe lock product

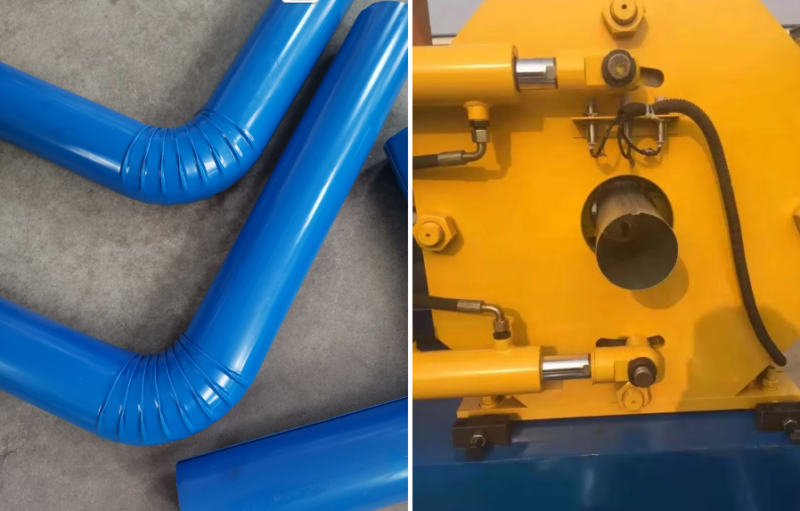

- This pipe lock product features a one-piece precision cast steel construction, effectively eliminating cylinder deformation due to welding, which ensures high accuracy. The piston movement and die operation are powered by a hydraulic source, allowing for smooth motion and rapid retraction without spring issues that could hinder mold opening and locking. Additionally, the front-and-rear cylinder locking design facilitates easy attachment of various shaped elbows.

- The hydraulic system comprises a motor, oil pump, solenoid valve, relief valve, and valve block, featuring a dual hydraulic circuit for both forward and backward movement. A hydraulic control check valve is included to enable quicker retraction, enhancing speed, reducing noise, and regulating system pressure.

- A double relief valve system is implemented, where the high-pressure relief valve activates during pressure pipe use to maintain elevated pressure, thereby increasing the pressure resistance of the extruded product. Meanwhile, the low-pressure relief valve engages when the mold opens, preventing excessive pressure on the oil seal to extend its lifespan.

- The mold base incorporates a dual bevel design to ensure even distribution of buckle pressure, promoting consistent force during crimping and maintaining uniform spacing of buckle lines without distortion.

- To guarantee mechanical precision and durability of the tube press, high-quality alloy steel and a specialized heat treatment process are employed for the locking mechanism assembly. The longevity of the pipe press is a result of careful material selection, effective heat treatment, precise machining, and thoughtful assembly and design..

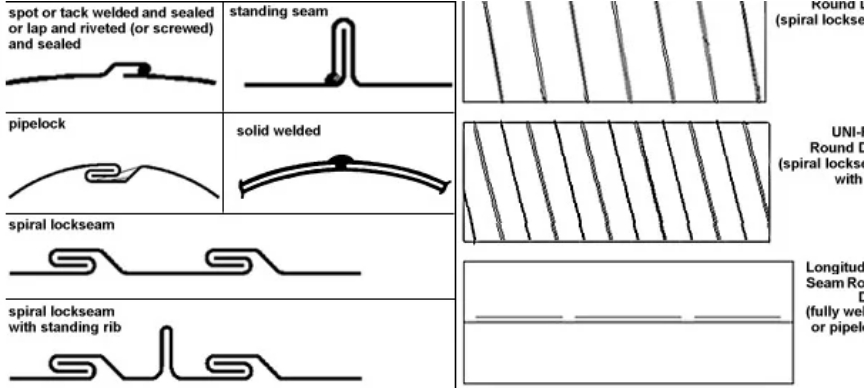

Here are some common types of lock pipe machines:

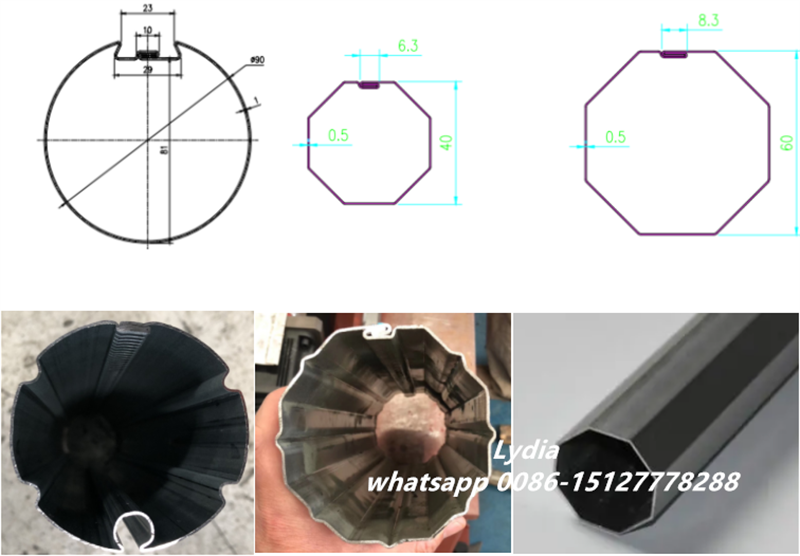

Good price good quality round downspout round pipe roll forming machine picture:

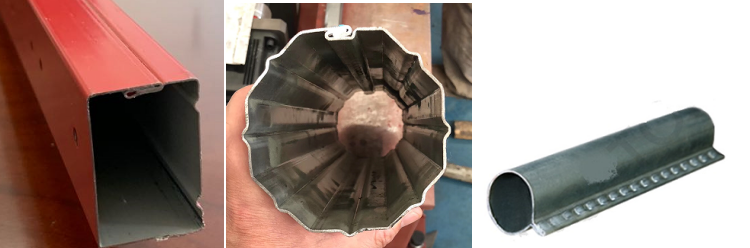

Downspout final product show:

The Technical Specifications Of Metal Downspout Pipe Roll Forming Machine :

Downspout Pipe Roll Forming Machine |

||

| 1.Formed Material | GI | Thickness:0.4 to 1.2 mm (standard) |

| 2.Decoiler | 3 Tons decoiler | 3 Tons Manual decoiler(will give you as free) |

| 3.Main body | Shaft diameter | 120mm |

| leveling rollers | 15 | |

| Material of rollers | Gcr15 | |

| Machine body frame | 400 H steel | |

| Drive | Gear and chains transmission | |

| Dimension(L*W*H) | 15000*1800*1600(customize) | |

| Weight | 5T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW*2 sets,Siemens brand |

| Hydraulic system power | 15 KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 8.Forming Speed | 25 m/min | The speed depends on the shape of the tile and the thickness of the material. |

More detailed pictures of the machine: