Mastering the Art of C Z Purlin Machines: An In-depth Guide on Operations and Applications

In the world of construction and infrastructure, the C Z Purlin machine stands as a game-changer. This innovative piece of technology has revolutionized how we design and build structures. But what is a C Z Purlin machine, and how does it work? Let’s dive deep into the world of purlins.

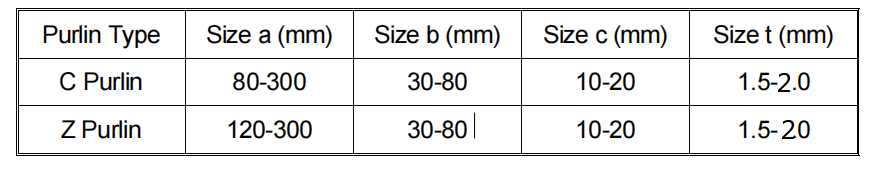

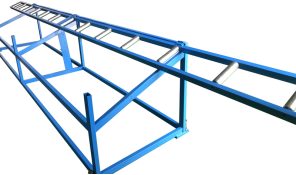

A C Z Purlin machine is a type of roll-forming machine used to create C and Z-shaped steel purlins. Purlins are horizontal beams that are used in the construction industry for structural support, particularly on roofs and walls of buildings. The ‘C’ and ‘Z’ denote the shape of the purlins that the machine forms.

The versatility of the C Z Purlin machine comes to life in its wide range of applications. They are commonly used in industrial buildings, garages, warehouses, and workshops among others. The strength and flexibility of the C and Z purlins make them ideal for these large structures, where they can provide necessary support and withstand a considerable amount of weight.

As for the composition of a C Z Purlin machine, it typically consists of several key components:

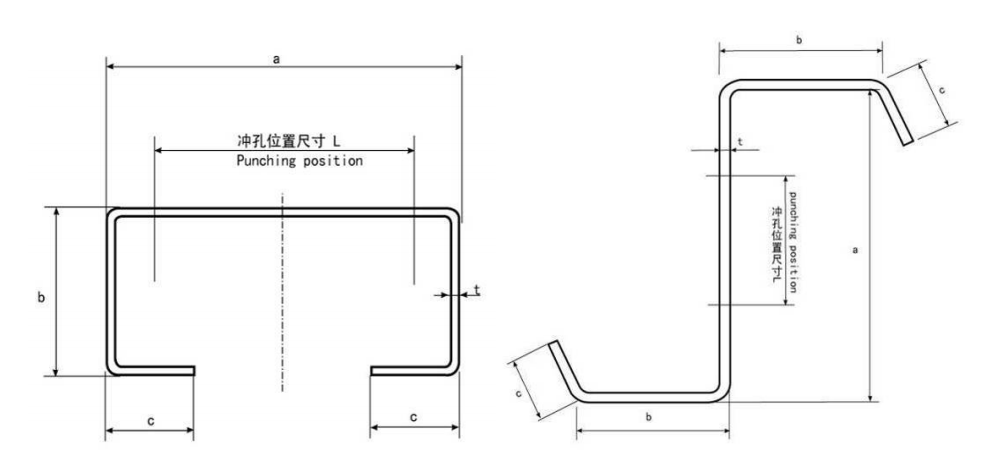

- Decoiler – This is where the coil of metal is held and gradually unspooled into the machine.

- Leveling System – This ensures the flatness of the metal strip before it enters the forming section.

- Roll Forming System – This is where the magic happens. The metal strip is bent into the desired C or Z shape here.

- Punching and Cutting Device – This is where holes are punched, and the formed purlin is cut to the desired length.

- Output Table – This is where the finished purlins are collected.

When it comes to operating the C Z Purlin machine, it involves a series of steps:

- Loading – The coil of metal is loaded onto the decoiler.

- Feeding – The metal strip is fed into the machine, passing through the leveling system.

- Roll Forming – The strip is then shaped into either a C or Z purlin in the roll forming system.

- Punching and Cutting – Holes are punched as necessary, and the purlin is cut to the desired length.

- Collection – The finished purlin is collected on the output table.

In conclusion, the C Z Purlin machine is an indispensable tool in the modern construction industry. Its versatility, functionality, and the value it adds in building sturdy structures are truly noteworthy. Whether you’re an industry professional or just a curious reader, we hope this guide provided a comprehensive understanding of this