Multi-Size Door Frame Roll Former Window Door Frame Making Machine with Width Adjustable

ZTRFM Door Frame Roll Forming Machine

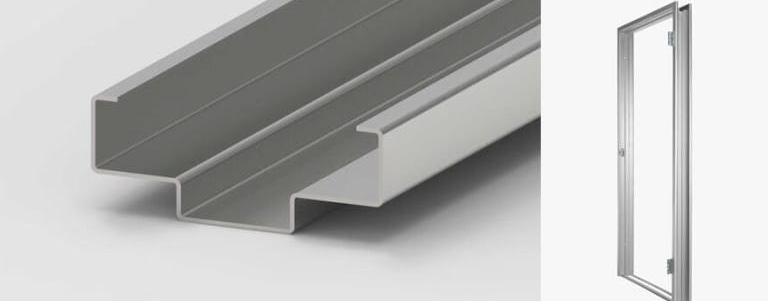

The Heavy Duty Multi-Size Door Frame Roll Forming Machine is specifically engineered to produce robust and stable steel window and door frames. This versatile machine can handle a variety of materials, including galvanized steel, carbon steel (CS), stainless steel, and copper, among others. The most popular choice among customers is the galvanized steel door frame machine, widely used in both residential and commercial construction projects.

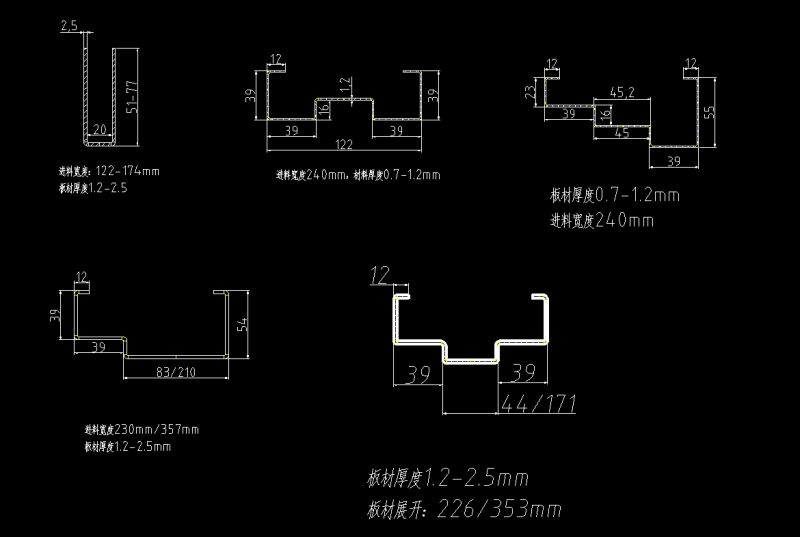

Designed to meet diverse country-specific standards, the machine can form door frames with widths ranging from 120 mm to 250 mm. This flexibility ensures that it can accommodate different building requirements across various regions.

The steel frame machine is powered by a gearbox and an electric motor, ensuring reliable performance even with thick and hard materials. To enhance durability, the rollers are mounted on shafts with an 80 mm diameter, allowing for long-term use at varying forming speeds.

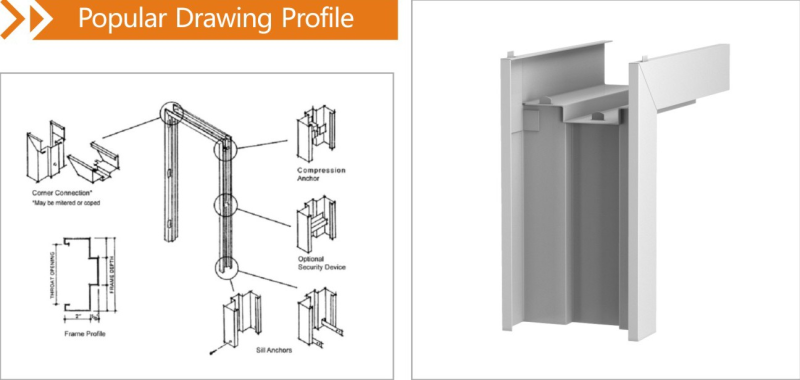

Steel door frames produced by this machine are custom-made to fit specific wall constructions and door sizes, offering unlimited possibilities in terms of design and application. ZTRFM specializes in providing tailored solutions, capable of preparing machines for any type of door frame profile required by customers.

Features and Advantages of the Door Frame Roll Forming Machine

Enhanced Production Efficiency

The door frame roll forming machine offers several advanced features to significantly boost production speed. Customers can opt for ground pit or overground accumulating units, continuous hole punching units, and flying tracking cutting systems with automatic stacking capabilities. These options streamline the manufacturing process, allowing for uninterrupted production and increased output.

Versatile Configuration Options

For multi-profile applications, the machine is available with a cassette-type platform and a quick-change machine base. This setup enables rapid switching between different profiles, enhancing flexibility and reducing downtime during production changes.

High-Speed Operation

Equipped with fully automated non-stop standard configurations, the door frame-making machine can achieve an impressive production speed of up to 30 meters per minute. This high-speed capability ensures efficient and timely delivery of products, meeting demanding production schedules.

The machine is designed to handle a wide range of coil sheet materials suitable for door frame forming:

– Material Types: Cold-rolled steel, hot-rolled steel, and galvanized steel.

– Thickness: Ranges from 0.8 mm to 2.0 mm, accommodating both standard and heavy-duty applications (0.8-1.3 mm, 1.0-1.6 mm, 1.5-2.0 mm).

– Yield Strength: Supports materials with yield strengths between 230 MPa and 300 MPa.

– Width: Customizable to meet specific profile requirements.

Summary of Key Benefits

– Increased Production Speed: Advanced accumulating units, continuous hole punching, and automatic stacking devices enhance efficiency.

– Flexible Profile Options: Quick-change machine base and cassette-type platform allow for easy adaptation to multiple profiles.

– High-Speed Operation: Capable of reaching speeds up to 30 m/min with fully automated configurations.

– Versatile Material Handling: Suitable for cold-rolled, hot-rolled, and galvanized steel, with a broad range of thicknesses and yield strengths.

– Customizable Widths: Tailored to fit various profile specifications, ensuring precise and consistent output.

By incorporating these features, the door frame roll forming machine provides a robust solution for manufacturers seeking to optimize their production processes and deliver high-quality door frames efficiently.

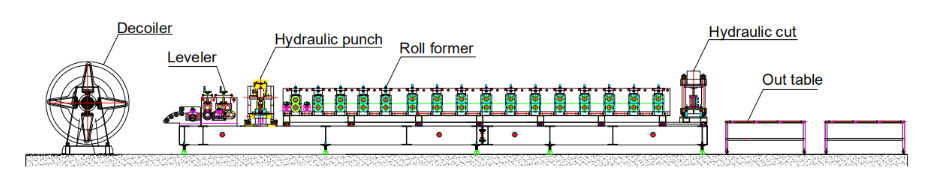

Flow chart:

The Technical Specifications Of Door Frame Machine:

| Series | Details | Parameter |

|

Product sheet |

Raw material | Galvanized steel |

| Material thickness | 0.9-1.2mm | |

| Sheet cutting length | Adjustable | |

|

Decoiler |

Work type: Passive type, Expand and shrink manually | |

| Structure:Steel channel welded for the basic frame | ||

| Usage:To support the coil and make the uncoiling, need the forklift or overhead crane to carry the coil on decoiler | ||

| Loading capacity: 3 tons | ||

| Inner diameter: 450-550mm (manual adjustment) | ||

| Manual brake system, with big hand driving wheel, easy to operate | ||

|

Rolling shaft |

Shaft material:45# STEEL | |

| Shaft type: solid shaft | ||

| Shaft diameter: 60 mm | ||

| Roll forming machine | Tempering treatment to prevent deformed and improve hardness | |

|

Roller |

45# steel | |

| 0.03mm Chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

| Rolling station | 18 rolling stations | |

| Work speed | 0-15 m/min | |

| Machine structure | Carbon steel welded structure | |

| Machine basic frame | 300# H steel welded | |

| Anti rusty treatment after welding | ||

| Work power | 11+11 kw | |

| Rolling spacer | Anti rusty treatment | |

| Steel bar | Anti rusty treatment | |

| Transmission | By gear | |

| Control system | Frequency brand | Delta (original) |

| PLC brand | Delta (original) | |

|

Hydraulic system |

Work type | Hydraulic cutting |

| Driving method | By pillar type Cylinder | |

| Hydraulic motor power | 5.5 kw | |

| Cutter material | Cr12 with heat treatment | |

| Cutting length tolerance | ±1mm/3m | |

| Cutting feature | Steady and safe working condition | |

More Pictures Of Machine: