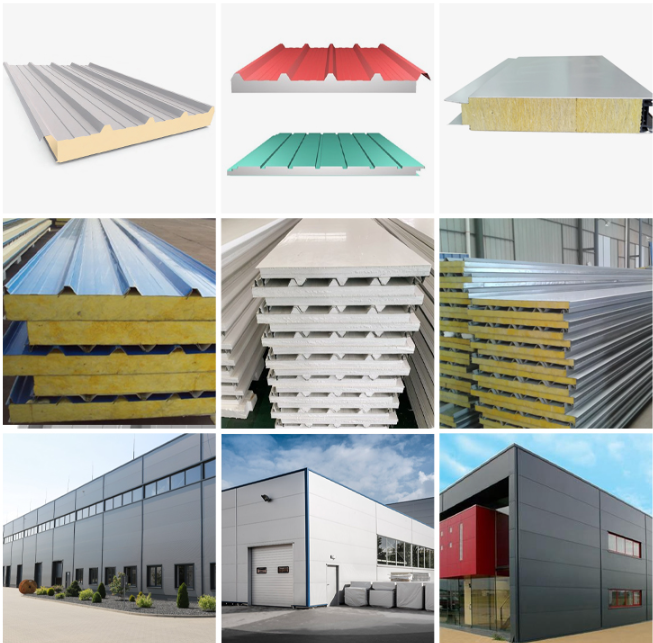

PVC/PET PPGI is a laminated material including a metal layer and a PVC film layer available in many different color patterns and emboss. Many options are available including solid colors, printed patterns, high-gloss options to satisfy various design requirements. This material can be used in typical metal forming processes such as bending, cutting, and pressing.This material can be used for outdoor applications by laminating a weather-resistant PVC film.

PPGI with PVC film is widely utilized in many different applications due to its excellent weatherbility, corrosion resistance and a variety of colors and patterns.

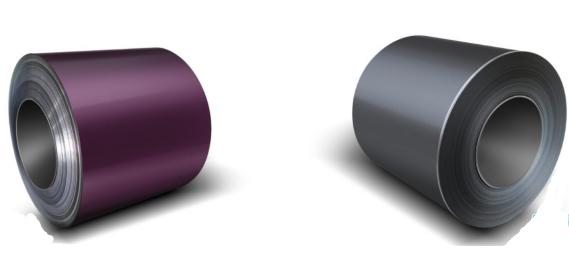

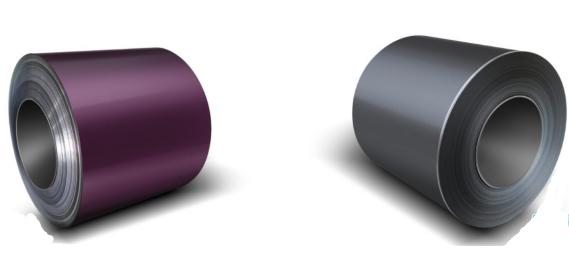

PPGI with fliming we have the following types for your reference:

PET coated steel sheet

Features:

Mode 1: PET coated steel sheet/coil

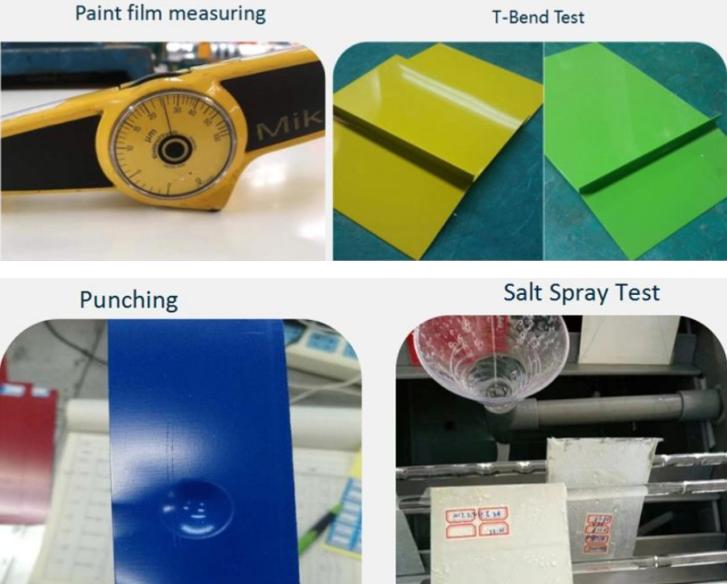

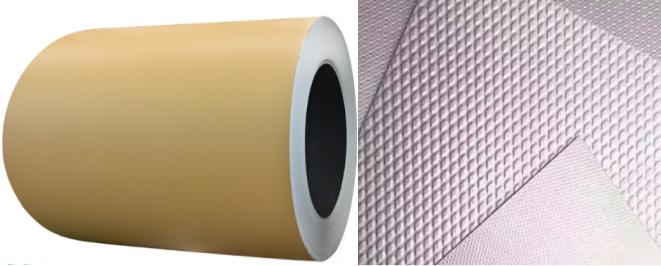

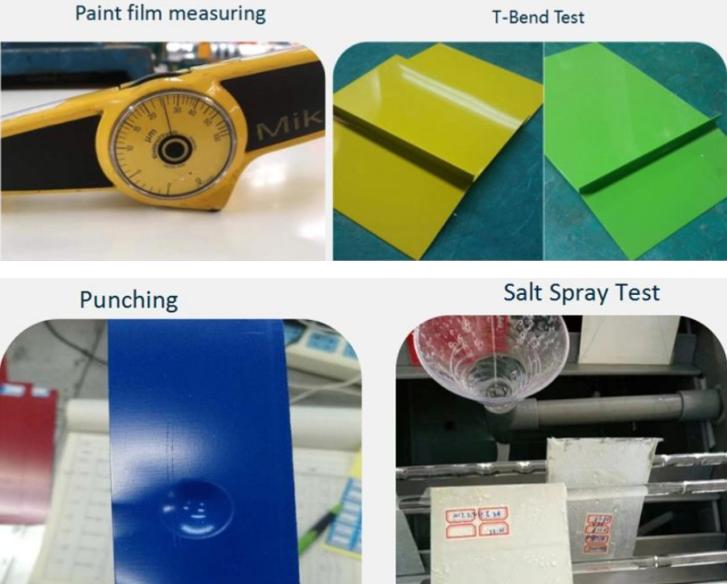

PET coated steel sheet is coated with a layer of film on the metal substrate. Use high-gloss film or phantom color film, or weather-resistant outdoor film. The board surface is laminated with a professional adhesive film. The laminated board has bright luster, a wide variety of colors to choose from, is waterproof and fireproof, has excellent durability (weather resistance, corrosion resistance, chemical resistance), anti-fouling ability, and superior UV resistance.

Where to use:

- Polyvinyl chloride resin decorative steel plate can be widely used for outdoor decoration and other purposes.

- PET coated steel plate The decorative steel plate is made of a composite film laminated with a PE barrier color layer on the steel plate. The appearance is gorgeous and beautiful as a mirror. (Olefin composite steel plate) It is made of olefin film, which can achieve the same performance effect.

- It is mainly used in the field of weak current system. Coated steel sheet) adopts environmentally-friendly special polyester film; it has been highly evaluated in the use of interior decoration building materials. T (propylene composite steel plate) non-vinyl chloride type weather-resistant decorative coated steel plate can be used for harsh outdoor decorative building materials and other aspects.

Mode 2: PVC coated metal sheet/coil

Features:

PVC coated metal sheet is covered with a layer of film on the metal substrate. Use high-gloss film or phantom color film, weather-resistant film, and heat insulation film. It is formed by hot pressing and laminating of polymer film. The metal coated sheet has bright luster, a wide variety of colors to choose from, is waterproof and fireproof, has excellent durability (weather resistance, corrosion resistance, chemical resistance), anti-fouling ability, and superior UV resistance.

PVC coated metal sheet is covered with a layer of film on the metal substrate. Use high-gloss film or phantom color film, weather-resistant film, and heat insulation film. It is formed by hot pressing and laminating of polymer film. The metal coated sheet has bright luster, a wide variety of colors to choose from, is waterproof and fireproof, has excellent durability (weather resistance, corrosion resistance, chemical resistance), anti-fouling ability, and superior UV resistance. The material and thickness of the base material are different for different brands of Hinai PVC coated metal sheet, and the material and thickness of the PVC coated metal sheet are also different. Polymer nano-coating is a new type of coating process, in which a layer of film and a metal plate are laminated through high temperature and high pressure.

Advantages PVC coated metal sheets:

- Anti-smoke: It is made of nano high-gloss film, easy to clean.

- Wear resistance: Proprietary film, sturdy and durable.

- Anti-moisture: The surface is coated with a film, which reduces the direct contact between water and the metal plate, and has strong durability.

- Good touch: There is a layer of film on the surface, and the touch is smooth, which changes the cold and single feeling of the metal material.

- Many designs and colors: a variety of colors to choose from.

- Anti-corrosion: The surface can use high weather-resistant outdoor film as the surface layer of weather-resistant film.

- Good heat insulation: heat-reflective heat-insulating aluminum foil film or weather-resistant outdoor cold film can be used as the heat-insulating surface layer on the surface. The temperature difference between indoor and outdoor can be increased by more than 8 degrees.

Mode 3: PVDF Metal Film Faced Panel

The antistatic agent added to the surface nano-ageing resistant film in the PVDF metal coated sheet increases the smoothness of the film surface, reduces the friction coefficient, and prevents electrostatic adsorption of dust. After 4000 artificial aging experiments by the Building Materials Inspection Center, the retention rate of solar reflectance was 82%, and the retention rate of gloss was 81%, and its anti-aging performance was better than the standard.

The antistatic agent added to the surface nano-ageing resistant film in the PVDF metal coated sheet increases the smoothness of the film surface, reduces the friction coefficient, and prevents electrostatic adsorption of dust. After 4000 artificial aging experiments by the Building Materials Inspection Center, the retention rate of solar reflectance was 82%, and the retention rate of gloss was 81%, and its anti-aging performance was better than the standard.

Where to use:

PVDF metal film-covered panels have a rich color range, whether it is for civil residences, large commercial outlets or large-scale exhibition centers, Hinai PVDF metal film-covered panels can add color to it. Good plasticity and machining properties make it an ideal material for various architectural shapes. Hina’s PVDF metal-clad panels have provided architects, designers and owners with a personalized color space for exterior walls and ceilings. It is also an ideal material for architectural modeling. Whether it is a multifunctional large-scale building or a unique and creative new-style building, PVDF metal-clad panels can always meet the different requirements of modern and classical architectural styles, making the building more colorful. The products have been applied in many fields such as electronic appliances, instruments, lighting, packaging, home decoration and so on.

Mode 4: PVF steel-plastic insulation board

The nano material of PVF steel-plastic heat insulation board refers to the material with a size between 0.1-100nm (1nm=0.000000001 meters), while PVF steel-plastic heat insulation board is a kind of plate in the field of building materials, which refers to the use of the upper surface of the base plate Nanomaterials are processed so that they are scratch-resistant and corrosion-resistant. The nano material of PVF steel-plastic heat insulation board refers to the material with a size between 0.1-100nm (1nm=0.000000001 meters), while PVF steel-plastic heat insulation board is a kind of plate in the field of building materials, which refers to the use of the upper surface of the base plate Nanomaterials are processed so that they are scratch-resistant and corrosion-resistant.

Advantages:

- Super anti-fouling: The surface of the Hinai PVF steel-plastic insulation board is smooth and delicate, dust and oil are not easy to absorb, and easy to clean, so the nano-panel has good anti-fouling properties, so it is widely used in the field of home appliances and furniture.

- Super abrasion resistance: The abrasion resistance of the PVF steel-plastic heat insulation board is more than 10 times stronger than that of general coatings, and it does not easily leave scratches.

- Antistatic: The contamination of dust is not only related to the particle size of the material, but also related to the effect of static electricity. Normal substances will generate static electricity under the action of electromagnetic fields. The status quo of static electricity is the result of contamination with dust. Hinai PVF steel-plastic heat insulation board eliminates static electricity and is not easy to absorb dust particles.

- Strong and long-lasting efficacy: The heat-resistant PVF steel-plastic insulation board has excellent acid resistance, alkali resistance and high weather resistance through the thermal coating process. The surface texture is delicate and shiny, the color is uniform and there is almost no color difference, and the color selection is rich and diverse. Showy and long-lasting, easy to match.

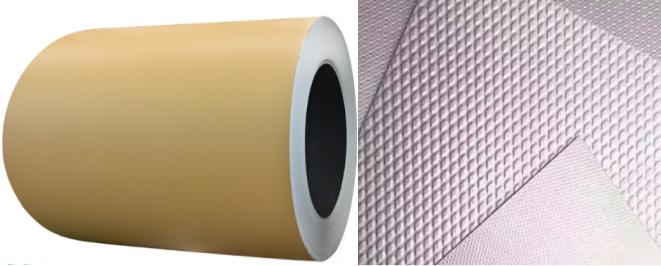

Mode 5: Cross-Linked Polyethylene foam felt PPGI coil

Cross-Linked Polyethylene foam felt with PPGI steel is a closed-cell foam with a compact feel and a resistance to water and normally used for metal roofign and absorb condensate water. To create a durable bond, the polymers are chained together and heated to make the “cross-linked” structure. Cross-Linked Polyethylene is commercially used for thermal insulation, expansion joints, and industrial gaskets. It can also be used for packaging.

Optional types of Cross-Linked Polyethylene foam: Cross Linked Polyethylene – 2LB, Cross Linked Polyethylene – 3LB Charcoal, 4LB Charcoal and others.

Features:

Chemically cross-linked foam is an extremely fine-celled foam, ideal for projects and applications that require thicker foam. With a smooth, pleasant feel combined with superior physical and chemical properties, our cross-linked polyethylene 2LB foam is the solution for an array of applications that demand thicker sections of closed-cell material. With its closed-cell density, this strong and reliable foam works well commercially as thermal insulation, construction expansion joints, and industrial gaskets. It is also used as packaging and in flotation equipment, with its low moisture permeability and high buoyancy.

And if you need to know more types, please contact us at any time.