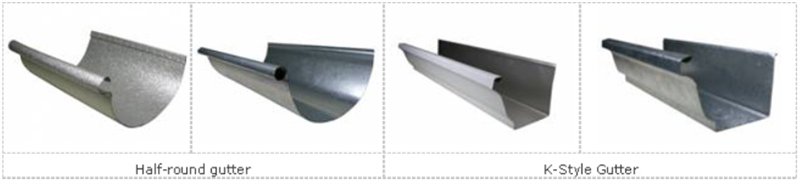

Different Designs of Gutter Forming Machines Made to Australia Market, Flat, high precision, tolerance within 1mm.

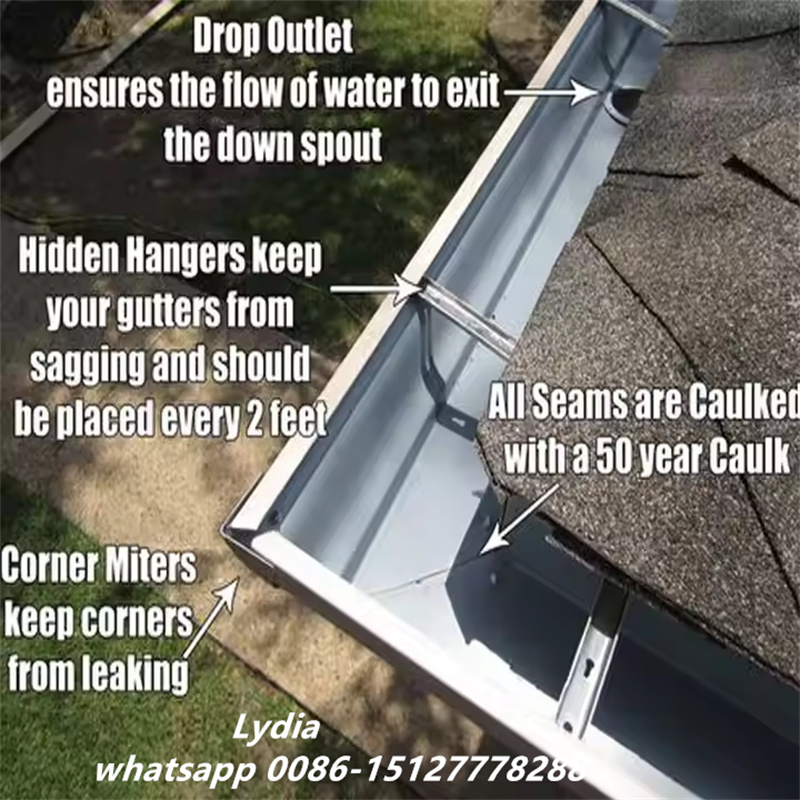

Applications of Gutter Roll Forming Machine:

Our goal is to deliver top-notch custom gutter machines and tools tailored for professional installation, offering high-quality products at competitive rates. This includes K-STYLE and Half-Round gutter forming machines designed for both residential and commercial applications, enhanced by our patented design technology.

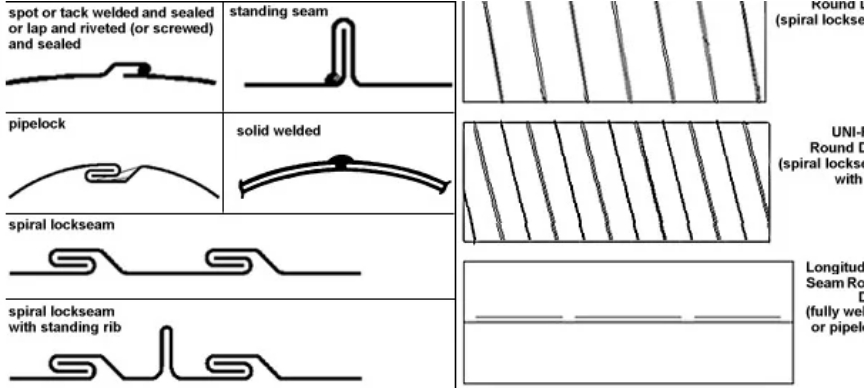

Half-Round gutters are installed along roof edges to channel rainwater away from the home and its foundation. Typically, a gutter system comprises sections of gutters, drop outlets, and downspouts. These systems can be crafted from various materials such as aluminum, copper, galvanized steel, galvalume, copper penny aluminum, weathered zinc, freedom gray copper, lead-coated copper, designer copper aluminum, paint grip steel, and copper plus.

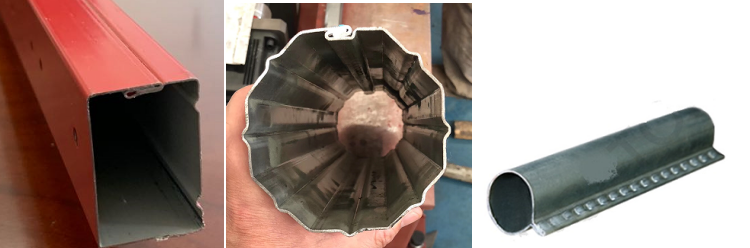

We provide a broad range of gutter machines to meet diverse requirements, including K-style, Half-round, and Box profiles. Our machines cater to both residential and commercial sectors. Additionally, we offer custom gutter machines designed to meet your specifications, whether based on gutter samples or detailed drawings.

Let me know if you’d like further adjustments!

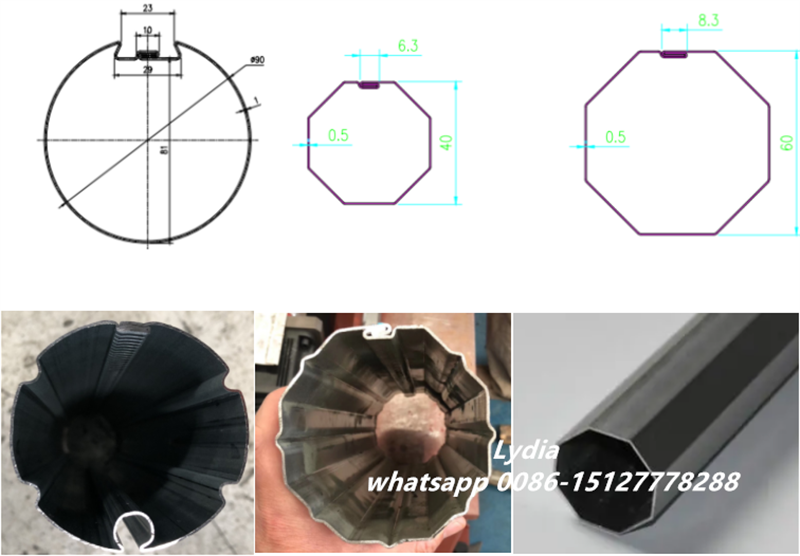

Profile Drawing:

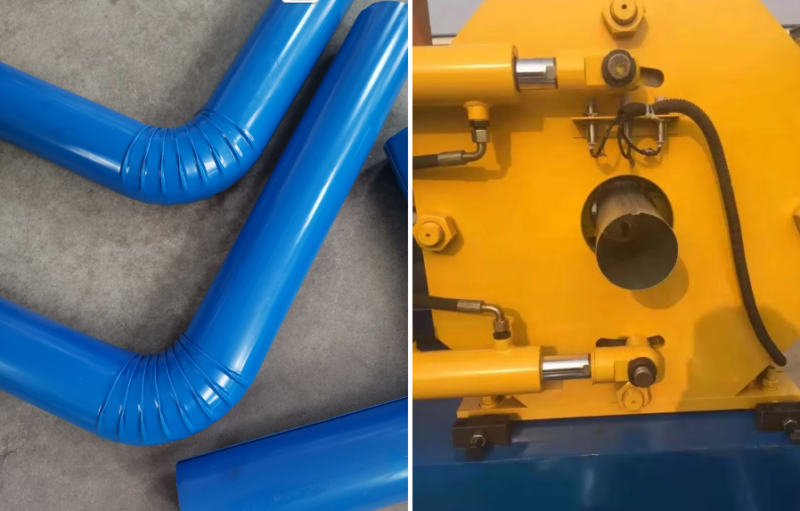

Product Display:

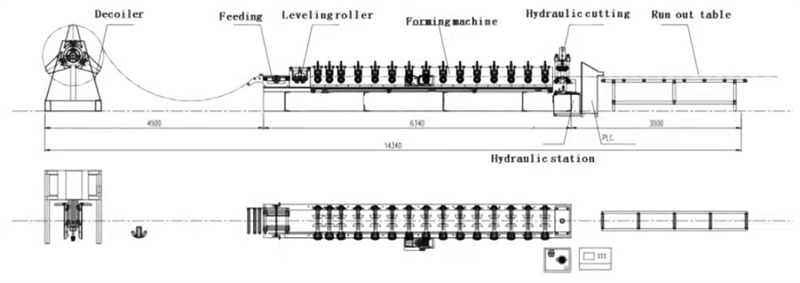

Technique parameters of the Gutter Roll Forming Machine processing line

Suitable material: Colored armor plate

Thickness of the plate: 0.3-0.8mm

Input width of the plate: Both decks is 1000mm

Productivity: 12m/min

Roller steps: 11 rows

Roller material: 45# steel

Diameter of active shaft: 70mm

Wall thickness of the main forming machine: 12mm steel plate (final design depends on your final profile

Main forming machine body: 300mmH steel

Transmission chain is25.4mm, Reducer is 5.5kw Xingxing Cycloid which works stably and no noise.

Cutting hydraulic system adapts CDF- 10 gear pump, the motor power is 4kw, no noise, work stably,PLC control system, easy to operate, high precision and work stably.

Dimensions of major structure: 3800mm*600mm*1500mm

Components of Gutter Roll Forming Machine Line:

No. Name Unit Qty

Decoiler set 1

Main machine for roll forming set 1

Control system set 1

Hydraulic system set 1

Post cut set 1

Output table set 2

Working Flow:

Half Gutter Machine Specification And Parameter:

| Types | Model |

| Working Speed | 15 –30m/min |

| Total power | 5.5 – 11kw |

| Hydraulic station pressure | 18-25Mpa |

| Max Dimension (LxWxH) | 12×1.4×1.5m |

| Weight of machine | 10 – 16 tons |

| Material width | 200-500mm |

| Material thickness | 0.5 – 1.2mm (G550-G300) |

| Suitable material | Colored/ Stainless/Galvanized Steel, Aluminum sheet |

| Roller station | 16 – 25 |

| Transmission system | Hydraulic motor |

| Cutting system | A non-stop flying cut , Hydraulic cylinder |

| Package system(option) | full automatically stacking system |

| Control system | PLC and servo motor control, human-machine interface, protection warning net, alarm light |