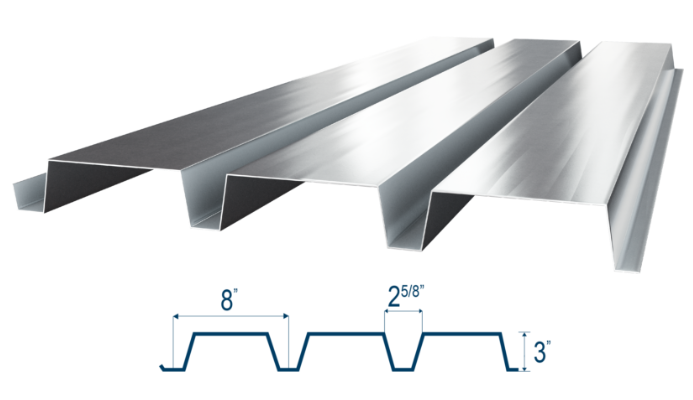

3.0’’ N Deep Rib Roof Deck Roll Forming Machine with Precision and Efficiency Malaysia Market

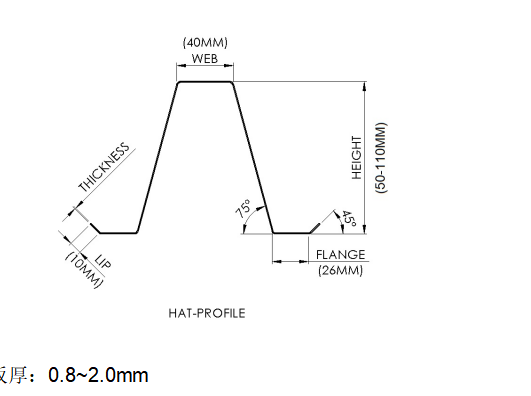

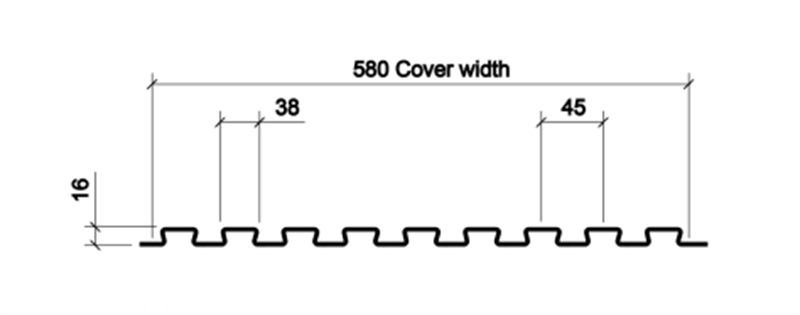

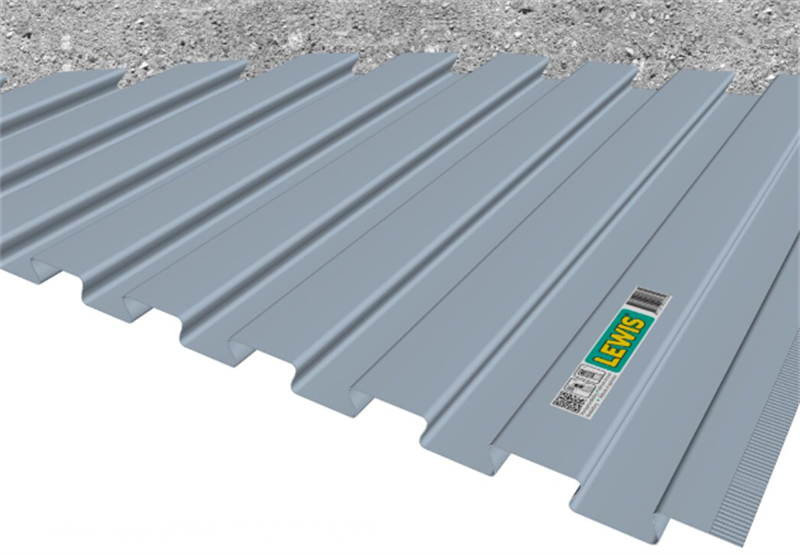

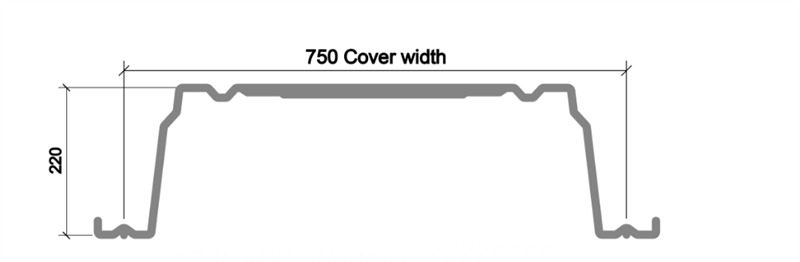

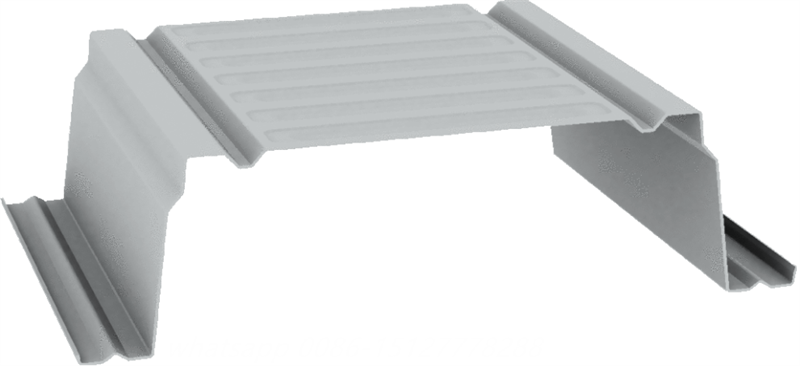

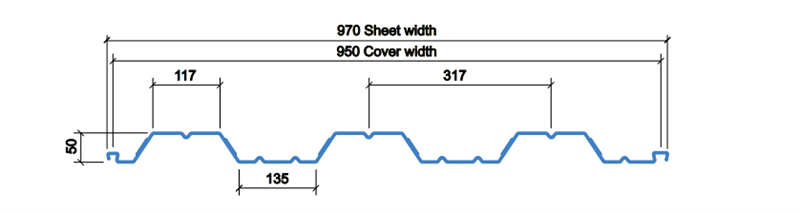

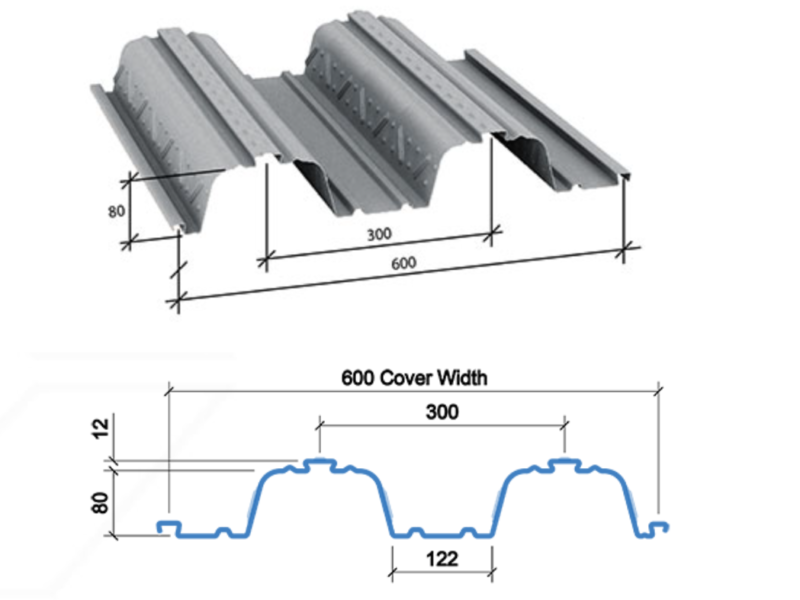

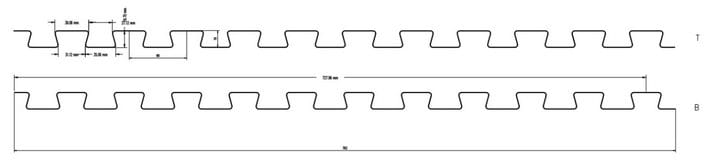

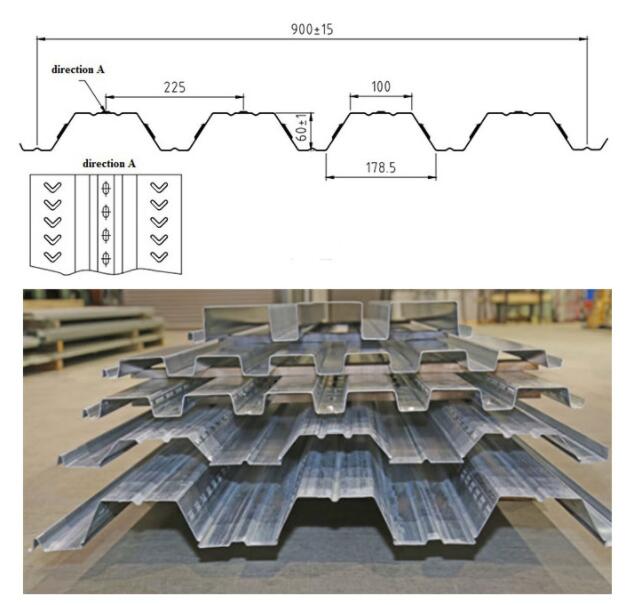

3.0’’N Deep Rib Roof Deck Machine Profile:

Standard Cover Width: 24″

Additional Cover Widths Available: 32″

Available Finishes: Galvanized-G60/G90, Galvanized Painted

Available Gauges: 20, 18, 16

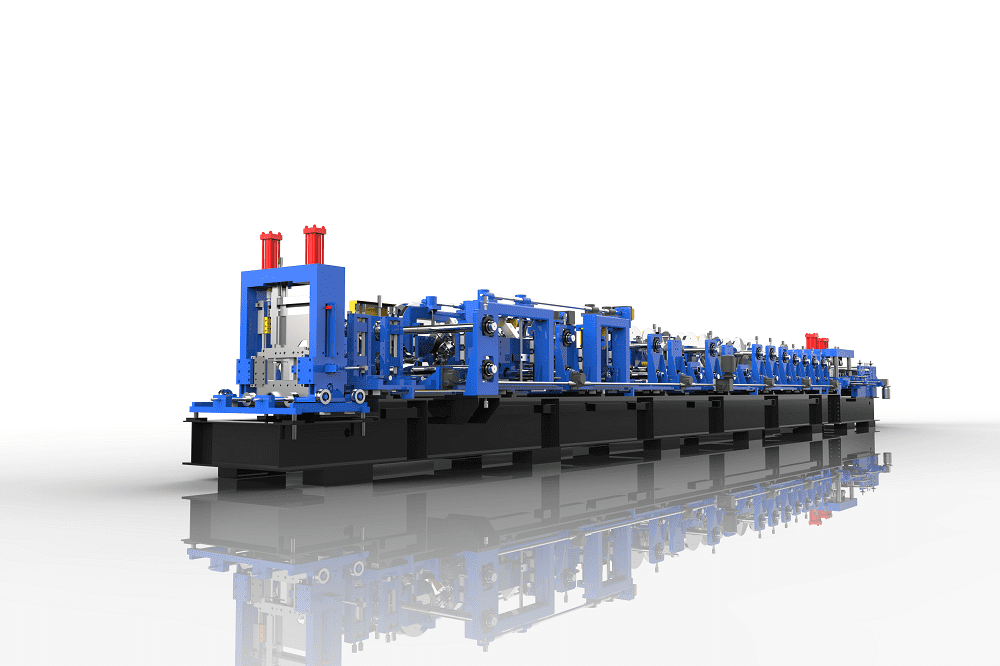

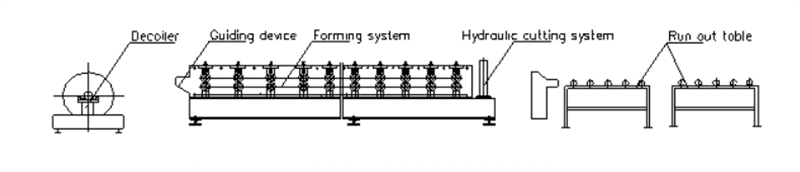

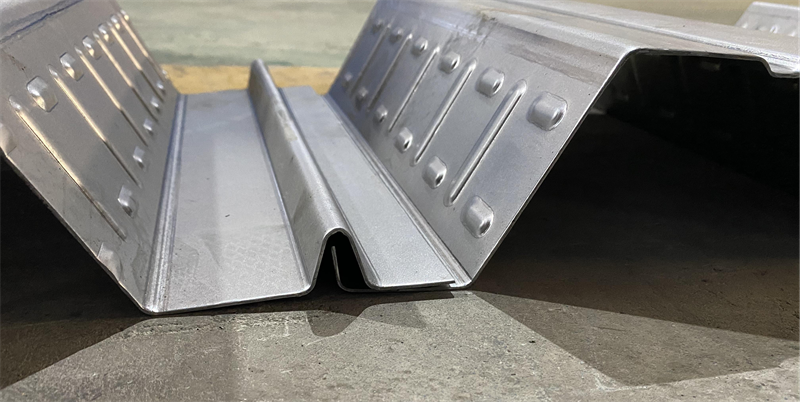

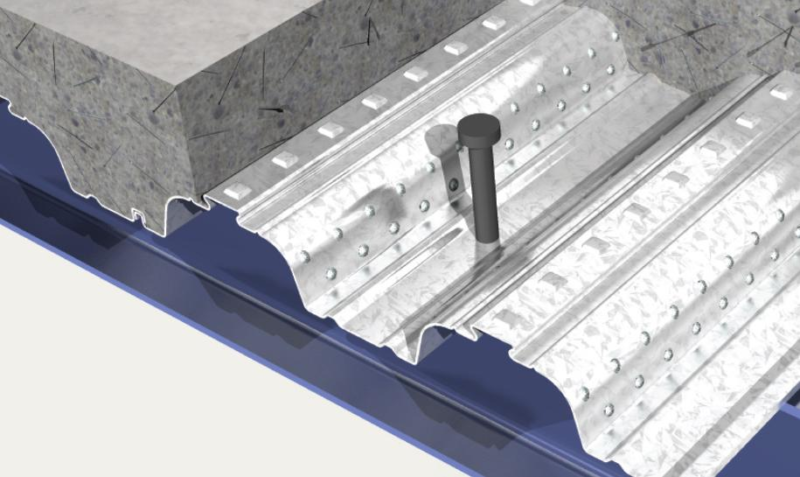

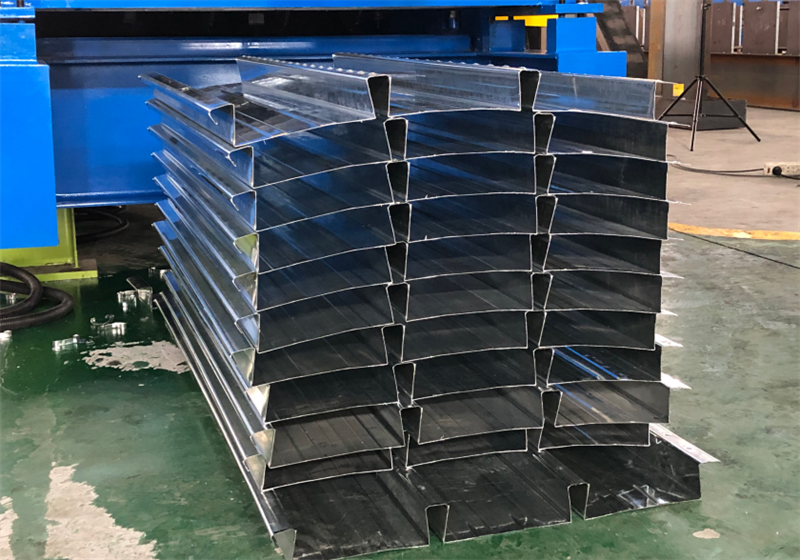

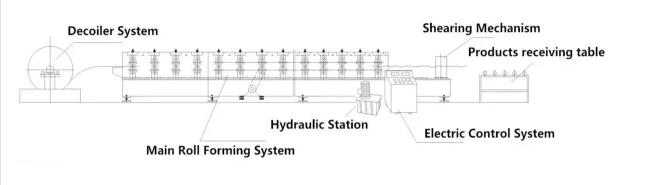

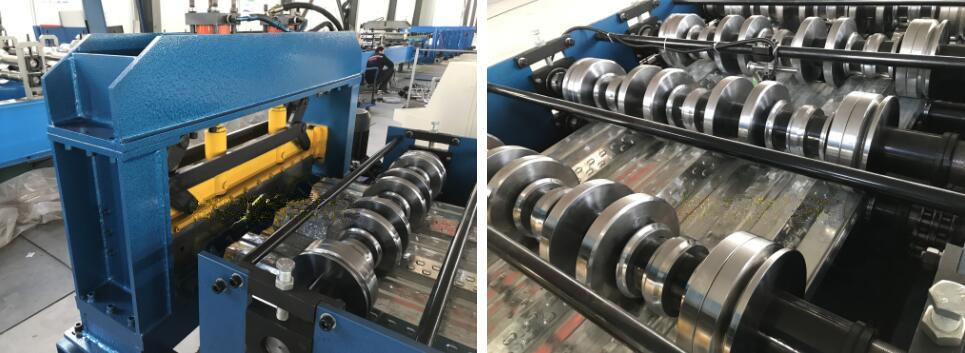

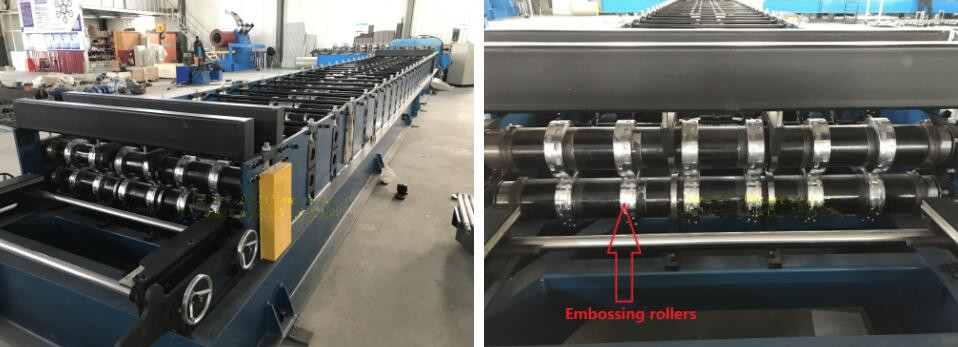

The machine in the below photo are the 3.0’’N Deep Rib Roof Deck machine we made before for our Malaysia customer.

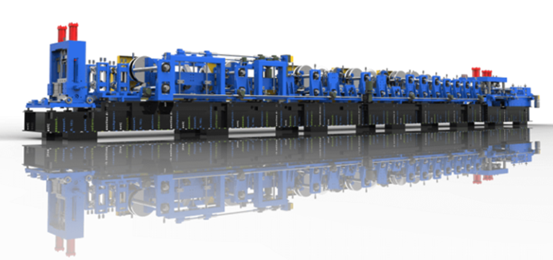

Zhongtuo 3.0’’N Deep Rib Roof Deck Roll Forming Machine: The Perfect Solution for High-Performance Roofing Systems

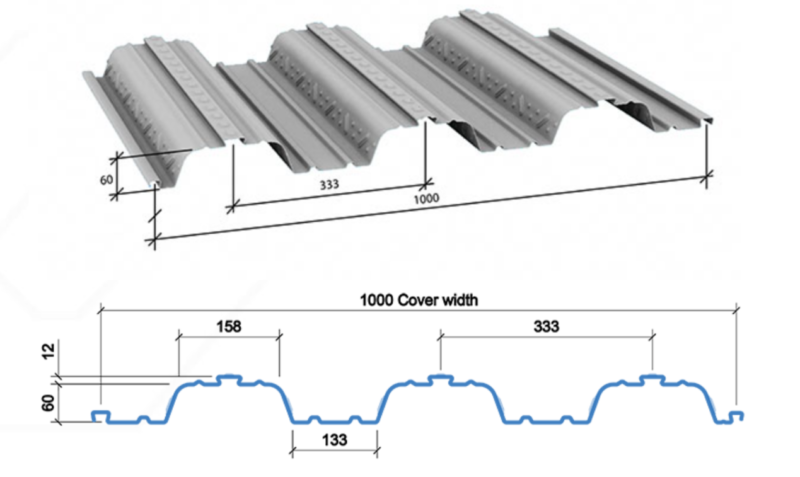

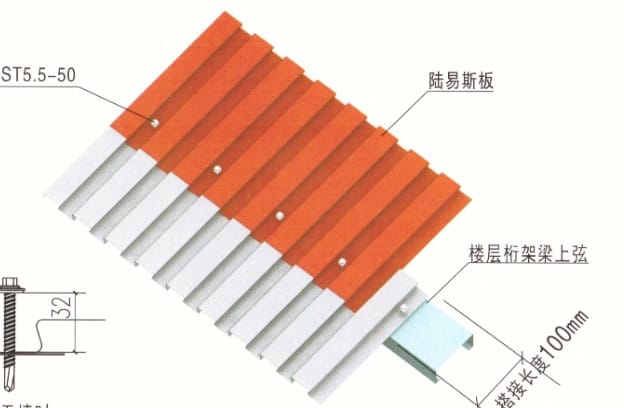

Zhongtuo’s 3.0’’ N Deep Rib Roof Deck Roll Forming Machine is one of our premier roll forming solutions, widely adopted across North America, including the United States, Canada, and Mexico. Particularly in the U.S., we’ve successfully delivered numerous machines to states like New York, Florida, Texas, and California. The roof deck profiles commonly used in the region include 1.5B, 2.0B, and 3.0B types, with material thickness ranging from gauges 16 to 22. These panels typically feature a 36” effective width and are processed from 48” wide galvanized steel coils.

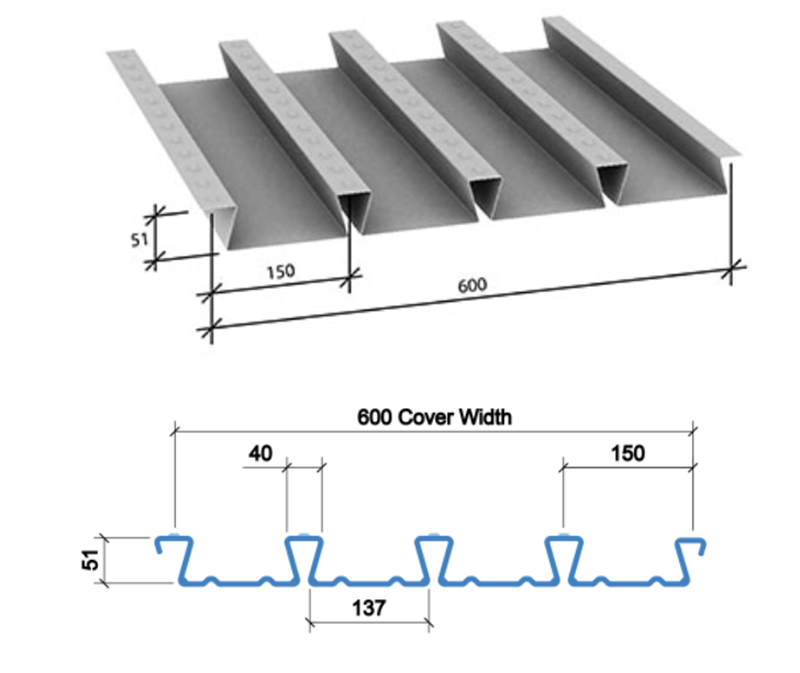

Profile Options Tailored to Your Needs

Customizable Machine Configuration

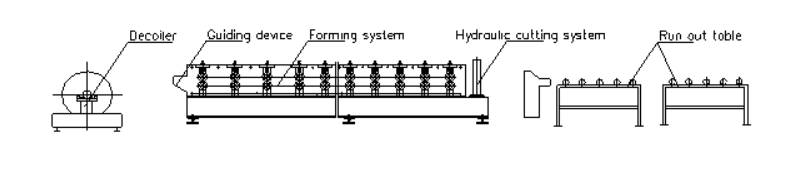

Zhongtuo offers multiple options to suit your unique production needs:

Decoiler Options:

Choose between manual and automatic hydraulic decoilers. For load capacity, we offer 5t, 8t, 10t, and 12t options. Our U.S. and Mexican clients commonly select 8t hydraulic decoilers, while some prefer 12t versions based on production volume.

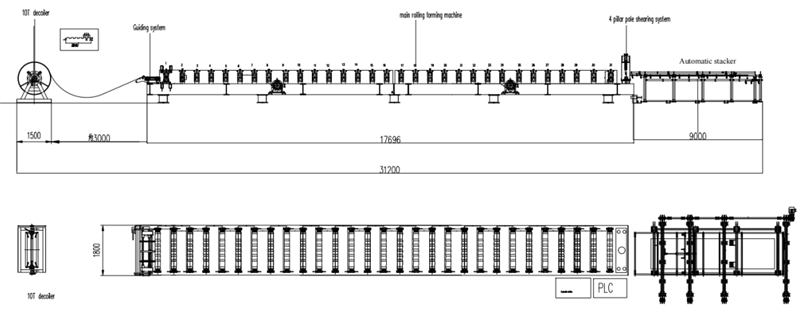

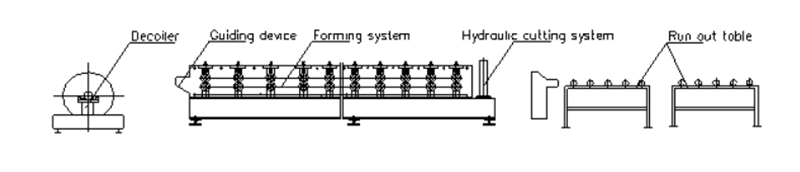

| 1 | Automatic hydraulic decoiler with loading cart | 1 set |

| 2 | Main roll forming machine (feeding-forming-shearing) | 1 set |

| 3 | Automatic deck sheet stacker | 1 set |

| 4 | Hydraulic station | 1 set |

| 5 | Electric control desk | 1 set |

| 6 | Spare parts as so on | Details in 7th page |

Transmission Choices:

The machine comes with a 2-inch double-chain drive with chain tensioners for durability. For customers desiring higher precision, gearbox transmission is also available at an additional cost.

Technical Specifications

- Machine Dimensions: Approx. 15,000 х 1,850 х 1,500 mm

- Weight: Around 5 tons

- Voltage: 480V, 60Hz, 3-phaseor as per request

- Frame: Constructed with 400 H-beam welded steel

- Roller Material: GCr15 quenched to HRC58-60

- Shaft Diameter: φ95 mm, crafted from precision-machined 45# steel

- Rollers: Approximately 28 stations

- Material Thickness: 8-1.5 mm galvanized steel, yield strength up to 550 Mpa

- Forming Speed: 0-15 m/min

- Drive Motor: 5 kW x 2, powered by a trusted Chinese brand

Enhanced Features

Hydraulic Shearing System:

Equipped with dual oil cylinders for stable and efficient cutting. The 7.5 kW hydraulic station ensures effortless processing of up to 1.5 mm thick materials.

Logo Press Integration:

Add custom branding during the shearing process. The logo mold is interchangeable for flexibility.

Stacking Options:

Choose between manual and automatic stackers in lengths of 6m, 9m, or 12m, enhancing efficiency during production.

Why Choose Zhongtuo?

At Zhongtuo, we prioritize performance, reliability, and customization. Our 3.0’’ N Deep Rib Roof Deck Roll Forming Machine is designed to maximize efficiency and meet diverse customer needs. Whether you’re involved in high-volume production or specialized projects, our machines deliver consistent results that support your business growth.

For more information or to request a quote, please feel free to contact us. Let Zhongtuo help you achieve your roofing and decking goals with confidence!