Good news! Successfully Explanation Light Gauge Steel Frame Keel Roll Forming for Construction in Chile

Dec. 16th 2025

Dec. 16th 2025

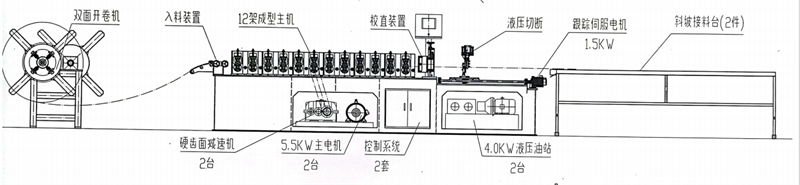

Investment Prospects of the 0.8-1.2mm Light Steel Frame Machine

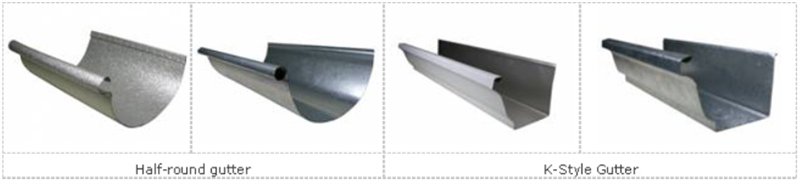

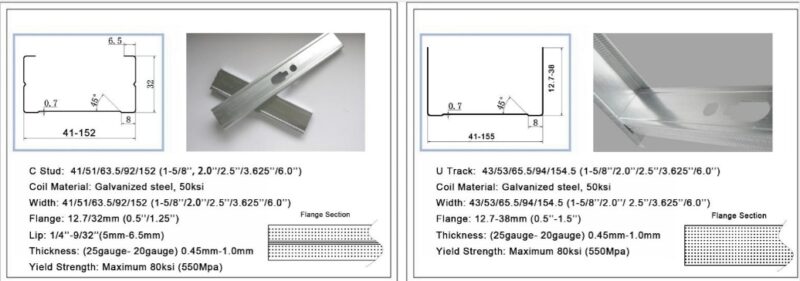

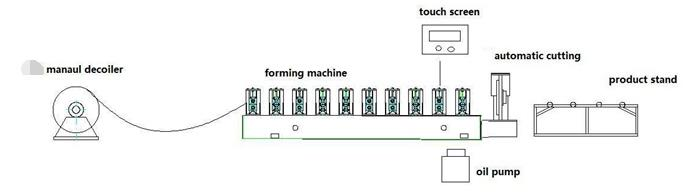

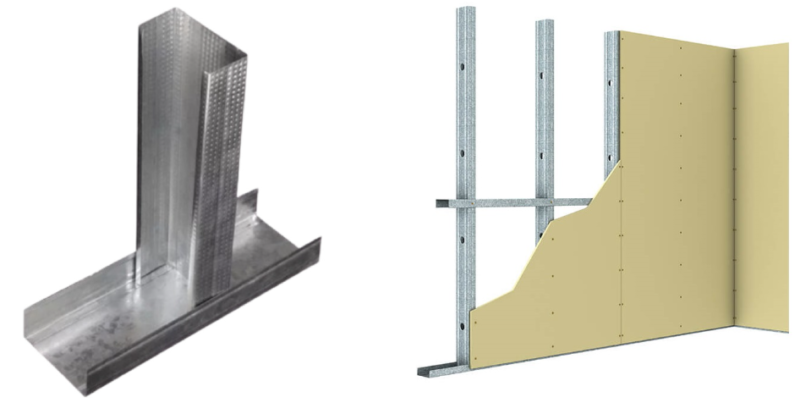

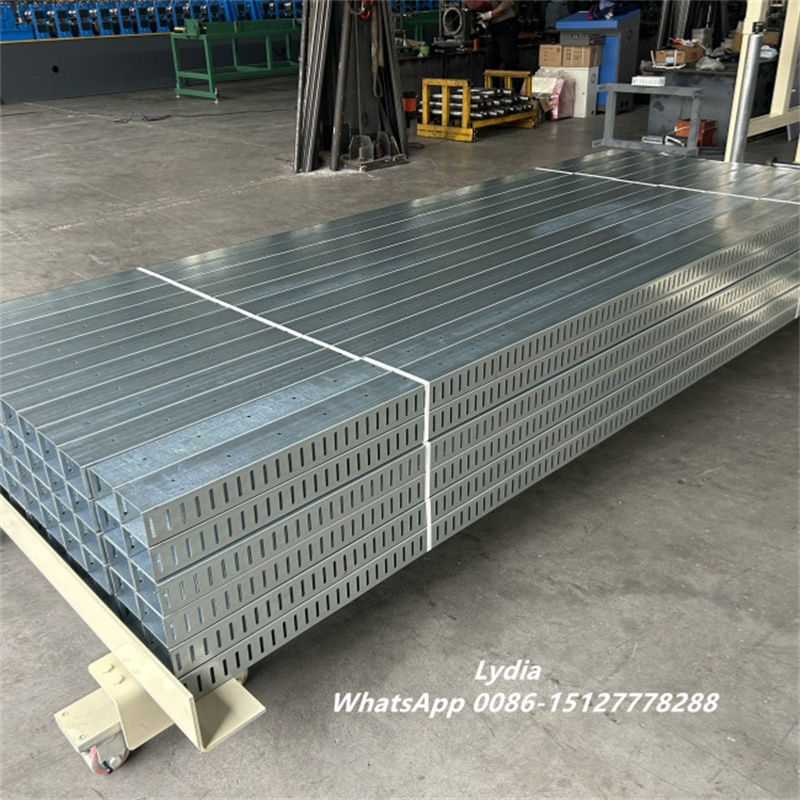

The(LGS frame machine) is a versatile piece of equipment used for producing profiles essential to LGS structural buildings. These profiles, created using advanced cold bending techniques, are assembled on-site into structural steel frames using screws and bolts. The completed frames can be integrated with insulating layers or coated with concrete to finish the construction.

This system is adaptable to various building types, including schools, residences, offices, hotels, hospitals, factories, and warehouses. The profiles produced by the light steel frame machine serve as an excellent substitute for wood in both residential and light commercial buildings. They are particularly suitable for load-bearing walls and interior partitions, offering a structural system akin to wooden frames but with notable advantages.

Benefits of Using Light Steel Frames

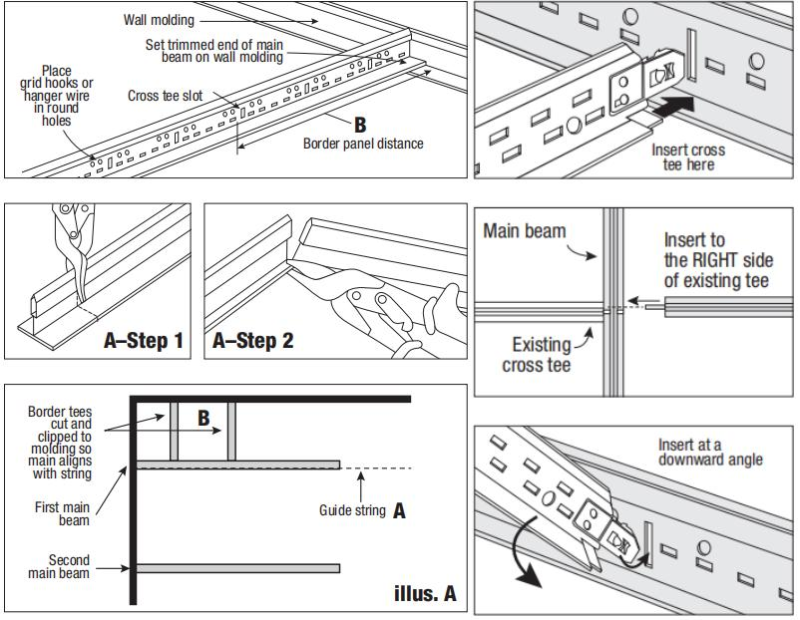

Ease of Assembly

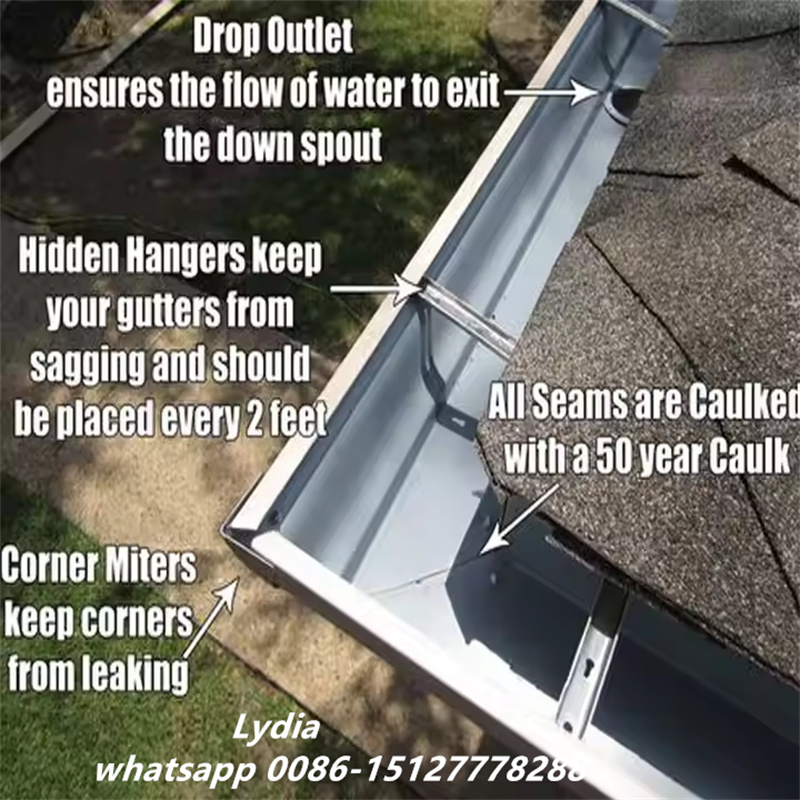

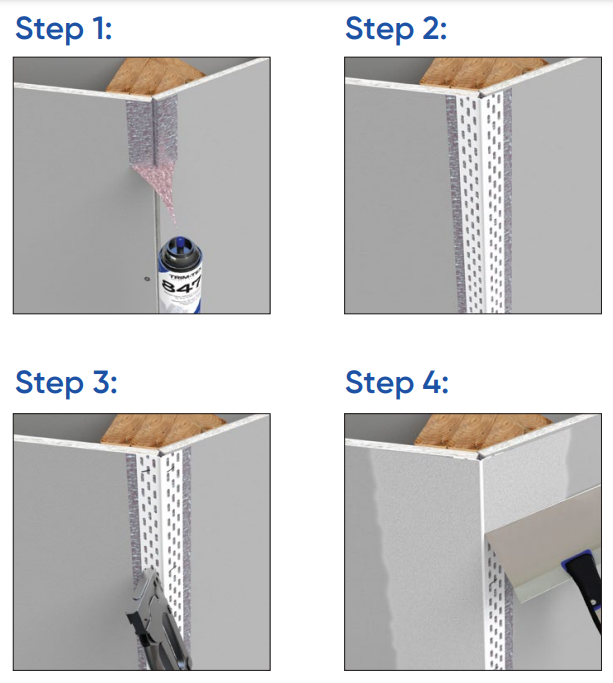

The profiles come pre-punched with screw holes precisely calculated during manufacturing, significantly reducing the need for on-site drilling or measuring. This feature streamlines the construction process, saving time and labor.

Lightweight and Cost-Effective Transportation

Due to their light weight, these steel frames are easier and more economical to transport compared to traditional materials.

Simplified Construction Process

With fixed profile dimensions and straightforward assembly methods, construction using light steel frames is faster and more efficient, allowing for quick project completion.

Durability and Resistance

Unlike wooden frames, steel frames are resistant to rot, warping, shrinking, splitting, burning, and termite damage. This makes them a reliable choice for long-term structural integrity.

Eco-Friendly Waste Management

Steel frames generate minimal on-site waste, reducing debris removal costs. Additionally, any waste materials can often be recycled, potentially generating revenue to offset project expenses.

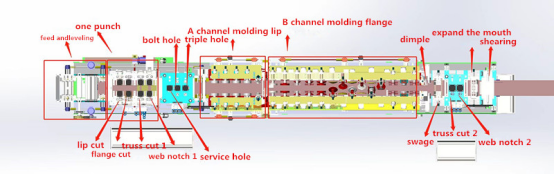

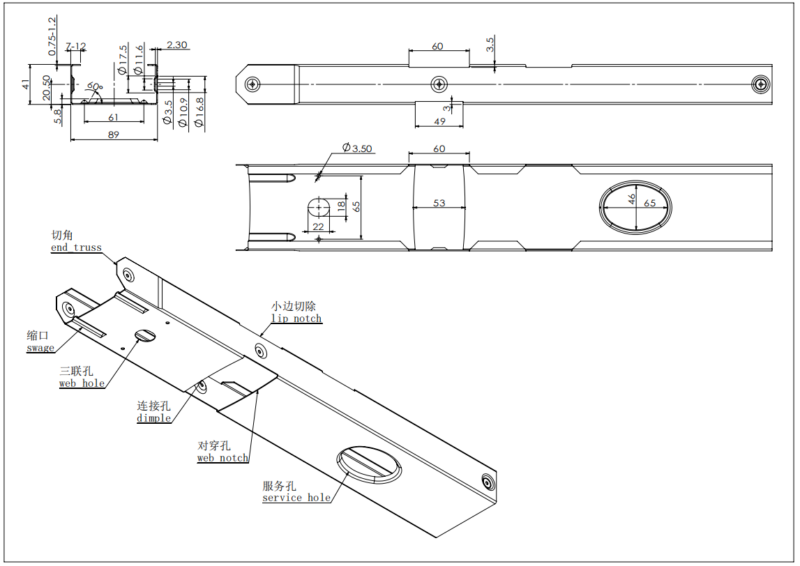

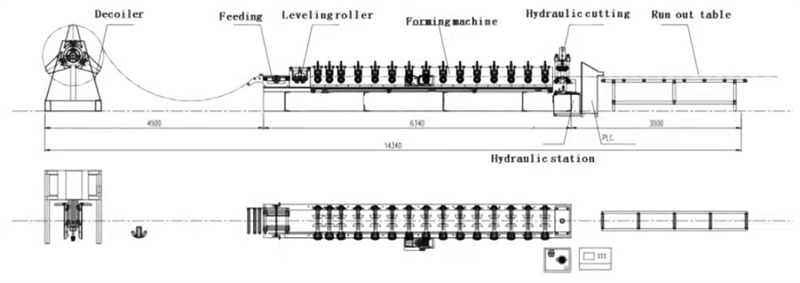

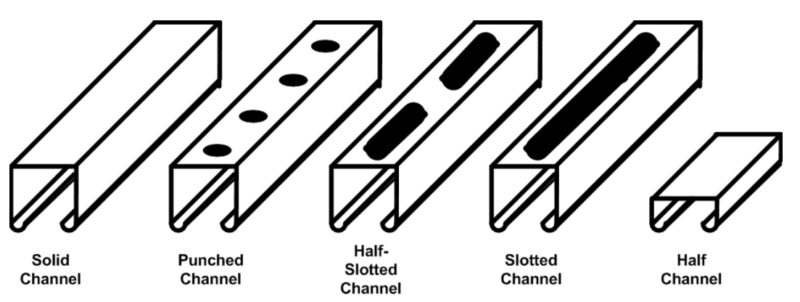

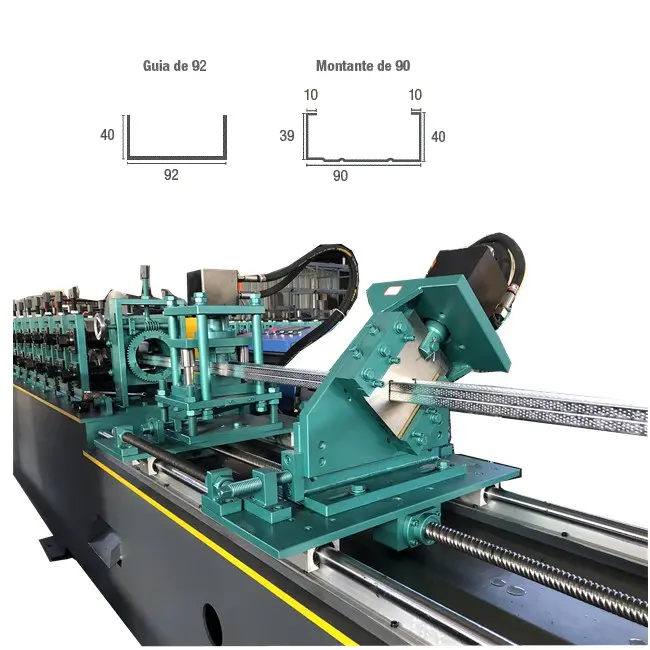

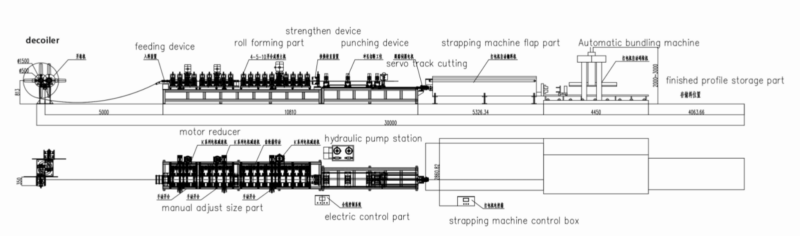

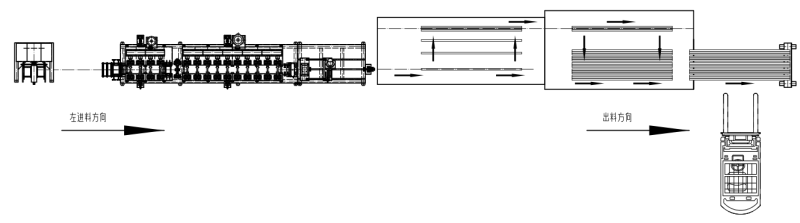

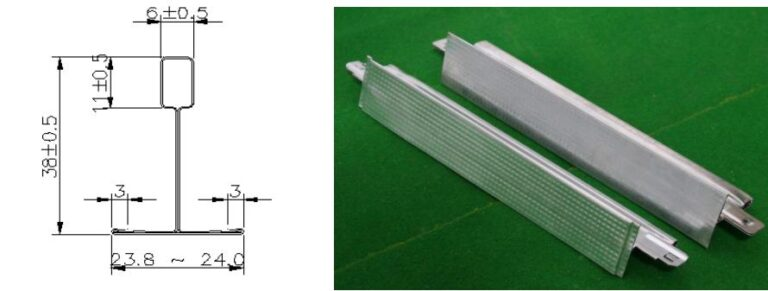

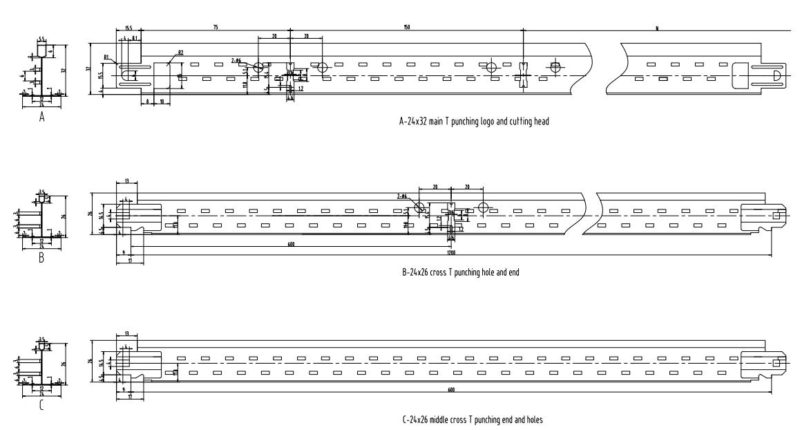

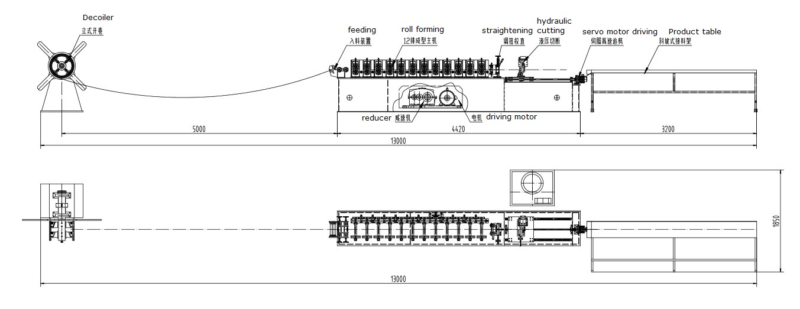

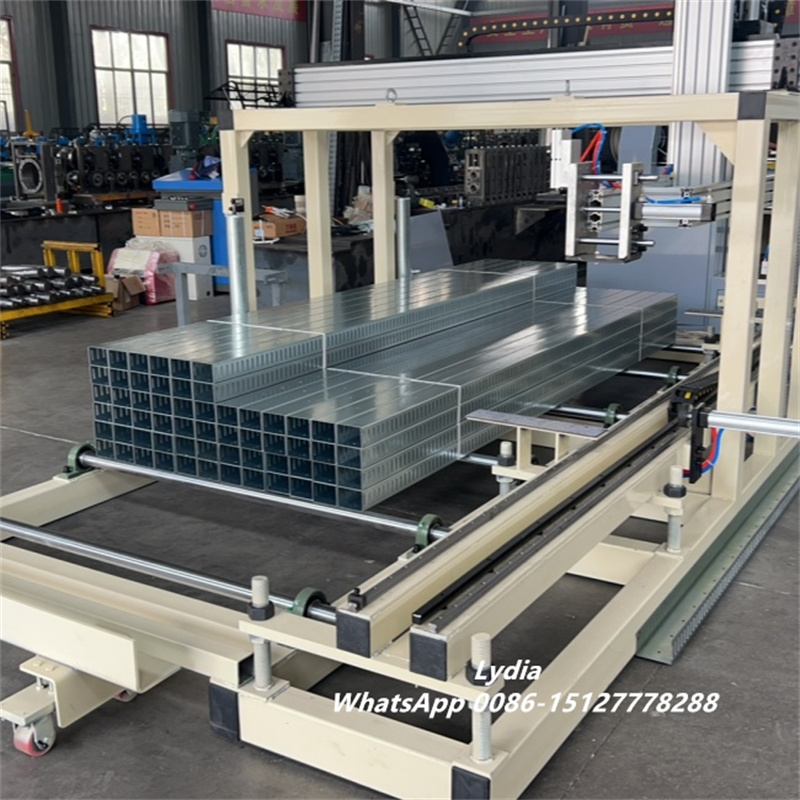

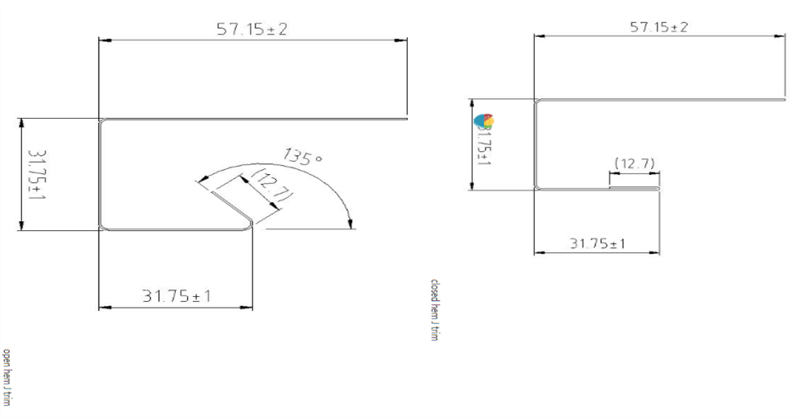

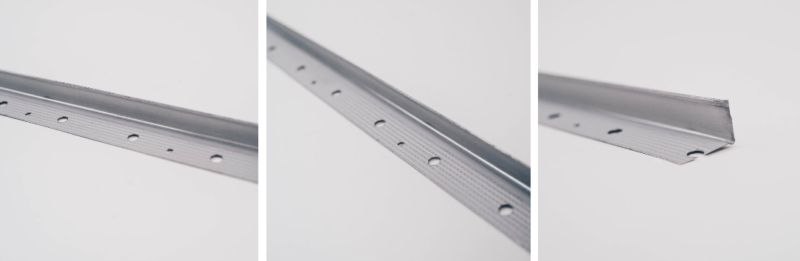

Structure of Light Gauge Steel Framing Machines

Horizontal and Vertical Beams:

- These beams act as the primary supports of the keel system, forming the structural framework.

- Connected securely using fixings and connectors, they provide the LGSwith foundational stability, akin to a skeleton in a human body.

- Installed based on specific design requirements, keel boards enhance the structure’s stability and load-bearing capacity.

- They enable the LGSto withstand various external forces, such as wind and seismic activity.

Understanding the highlights its critical role in LGS construction and decoration. By mastering the materials, structural components, and installation techniques, builders can achieve a safe, durable, and aesthetically pleasing result.