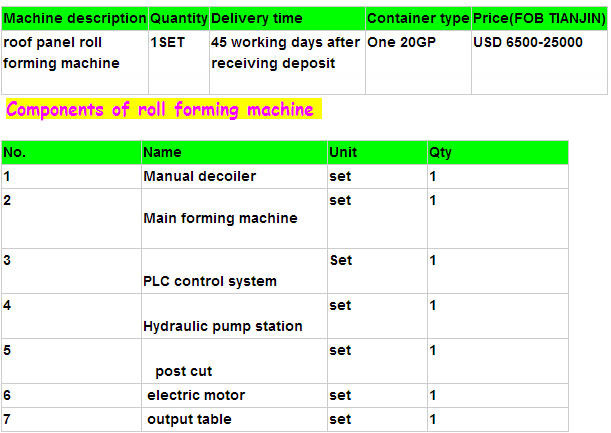

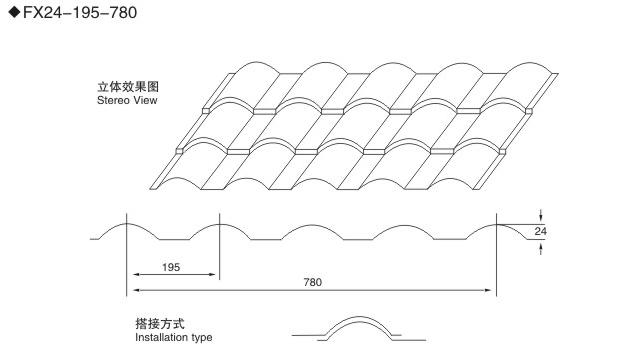

Steel Sheet Curving Machine Drawing

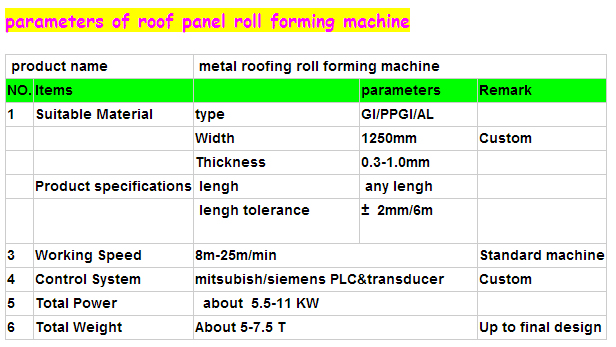

Steel Sheet Curving Machine Technical Parameters

1.Motor Power:2.2 Kw

2.Drive Sprocket: 12A-1

Number of Rolling Stations:5

Unit Dimensions: 1.5 m long, 3.0 m wide, and 1.5 m high

Punching Die Material: 90Gcr

Heat Treatment of Punching Die: HRC52-55°C

Loading cut to length Accuracy:100mm±0.3mm

Rolling Material:45# Steel and PU,surface: hard chrome plated

The single face of Cr electroplating rollers: 0.05mm

Hydraulic Station Motor Power:5.5 Kw

Cylinder Specifications: Φ180mm*80mm

Siemens PLC is adopted

Shenzhen MCGS touching screen operation panel is adopted

Converter is Siemens

Voltage: 415V 50HZ 3P

Drawings for profile/blades/electrical/installation will be provided

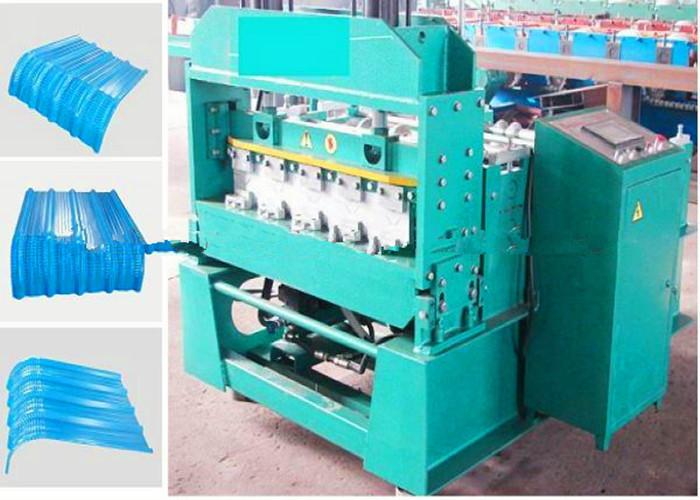

Product Function

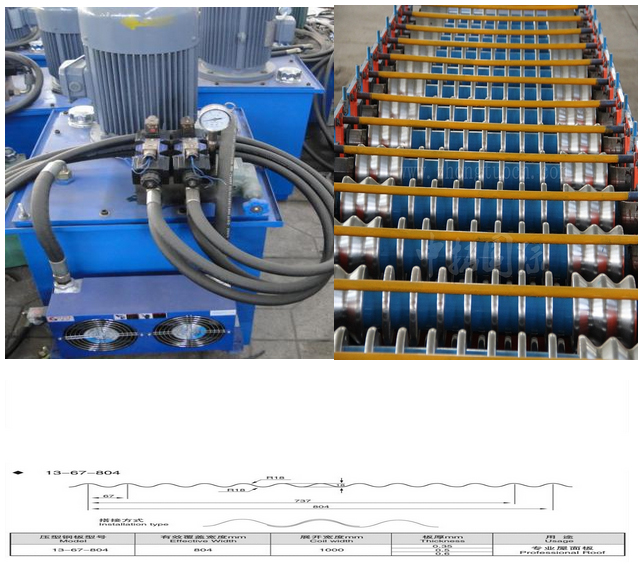

This machine makes small-span curve for designed profile roof panel.

Such a curving steel sheet saves roof purlins and steel farme,

and lowers cost accordingly. Moreover, the curving roof is strong and durable,

and looks beautiful and fashionable as well.

APPLYCATION

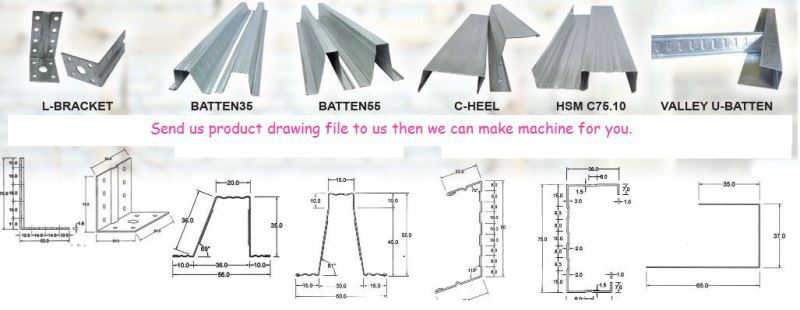

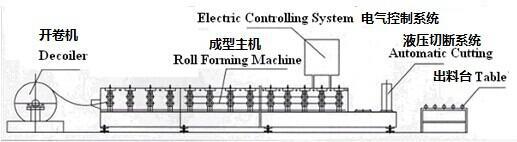

RELATIVE MACHINE

Company Information

Our enterprise,Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd,as the professional and leading manufacturer,can manufacture,design,installation and debug various roll forming machines and metal processing sheet equipments,which produce metal roof wall panel,glazed roof tile,CZ steel purlin,floor decking,roof ridge cap,sandwich panel,roof truss,shutter panel,shutter slat,door frame,guardrail,and metal sheet uncoiler,bending,slitting,cutting,flattening,punching,crimping.

Backed by reasonable design,precision machining and selected material,both our standard and customized machines are characterized by long life,precise forming and easy operation.With our customers trust,our machines have been sent to America,Australia,Russia,India,SriLanka,Nigeria,Pakistan,Uzbekistan,Mozambique,Angola,Turkey,Brazil,etc.

Warmly welcome to China to visit our factory and select the machines you need.