tile roof forming machines

Different tile roof forming machines can produce different shapes of steel tile roof sheets in various thickness and colors. Steel tile roof sheets are the new substitutes for traditional clayey, concrete tiles. They are popular because of their low cost, short building period, re-cycle use, and elegant appearance. They are used as the roof of villas, luxury houses, theatres, exhibition centers, etc.

Detail information:

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness: 0.3—0.8 mm

Material hardness: 195 mpa—350 mpa

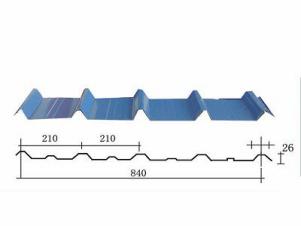

Material width: 1250 mm

Formed width: 1100 mm

Glazed Tile are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and different kinds of greenhouses. What’s more,

equipment can be designed and manufactured as customers’ requests.

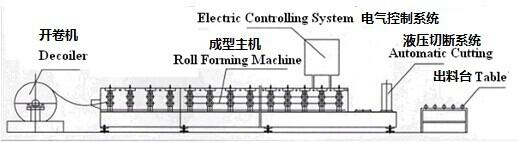

Forming device:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Feature : Ensure stability , precision and lifetime.

Shearing Mechanism:

Advanced hydraulic drive, automatic punching and cutting after forming, no

distorting or wasting, high level safety factor.

(include cutting tools, hydraulic tank, cutter machine)

| Blade Material | Cutting system |

| Cr12 quenched | Full automatic |

Counter:

One counter gauges length, pulses, and decides length. Omron encoder for length

Measurement.

Controlling device:

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with

stability, precision and lifetime.

2.Other electric element are Delta

3.Equipped with movable switch, air break, radiator, transformer & electric leakage

protector for operation convenience and safety.

| Screen | PLC |

| Text screen displayer | Taida DVP14ES from Taiwan |

The service:

1.We can improve some free tool and some parts.

2.If there is any problem found of the machine, we will repair it for free in one year.

3.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

4.Without visiting, we will send you user manual and video to teach you to install and operate.

We also have some another kinds of cold roll forming machine . If you need this kinds of machine or another kinds of machine such as ceiling keel roll forming machine ,Tee bar roll forming machine,color steel roll forming machine and so on. You also can contact us.We will provide you the best cold roll forming machine.

You can contact with me cnzt008@zhongtuocn.com OR ceo@zhongtuocn.com