Glazed roof tile roll forming machine for India market

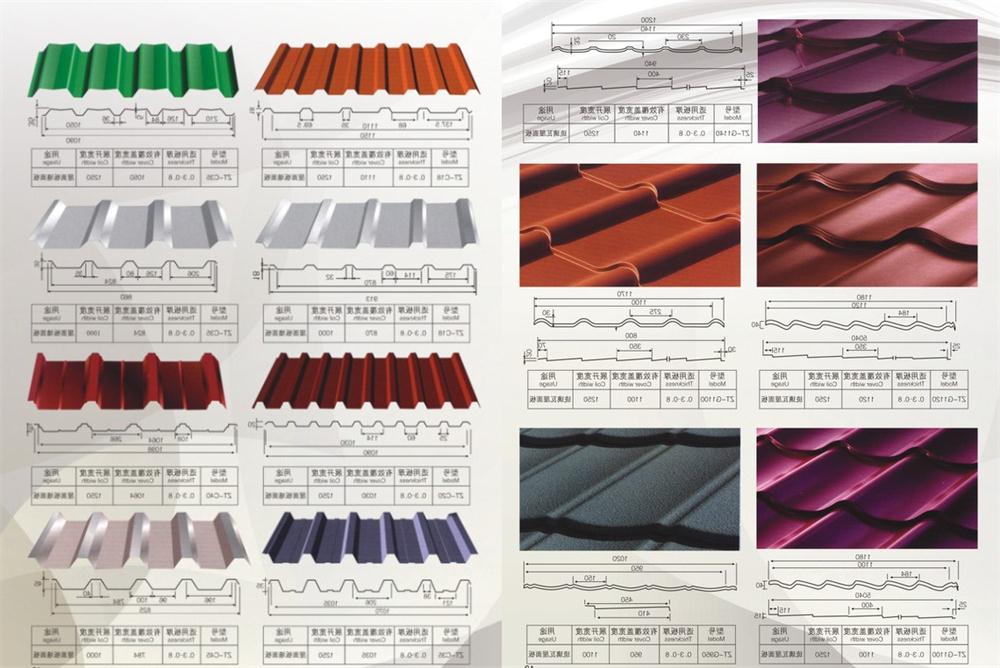

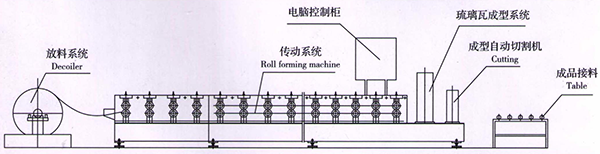

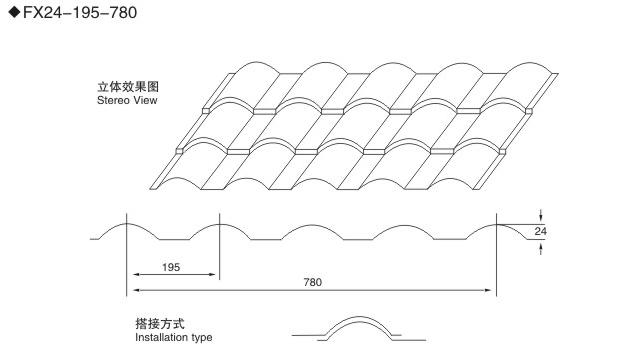

We have more and more Indian customers. So we have rich experience in making various types of machines for Indian customers. Especially we are professional in making glazed roof tile roll forming machine. We will show you a video about the glazed roof tile roll forming machine that took by Indian customer. The roofing sheet machine in the video is a kind of very popular glazed roofing sheet roll forming machine in Indian market, we have many customers from India, and this roof sheet profile is acceptable by almost all the customer from different cities of India, that is to say, this is a standard profile in India market. This glazed roof tile roll forming machine can use the material 1220 mm and 1450 mm, this is two width of the India steel coils. So you have two options, this is easy for you to prepare the material. We have produced many this same glazed roof tile roll forming machines for our India customers, if you have the same demand please let me know, I will give you a offer. And we have office in Mumbai, we can give you better after-sale service.