Zhongtuo wall angle roll forming machine, wall angle bead producer

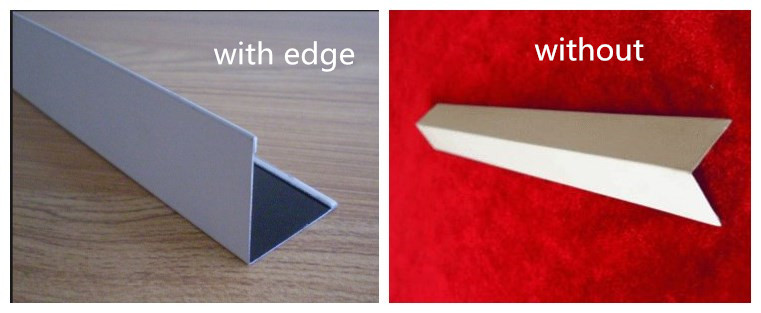

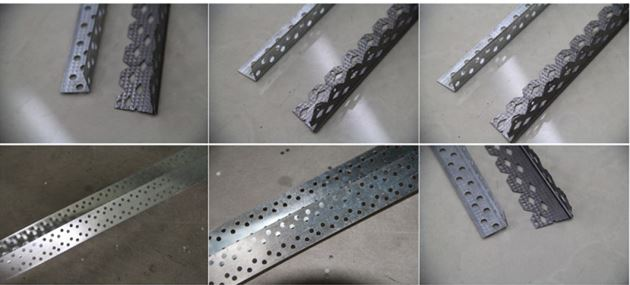

Wall angle beads normally will be used together with C channel, U channel and others and the sizes are different according to the customer needs. And for without punching wall angle, there are also two types, with folding age about 1mm or without folding edge. All those two types could be made by our machine one. Even If you have four to five different sizes needed, our machine also could make for you by our one wall angle roll forming machine.

Here is one picture for illustrating what I mean above:

All those two types could be made by one machine with various sizes.

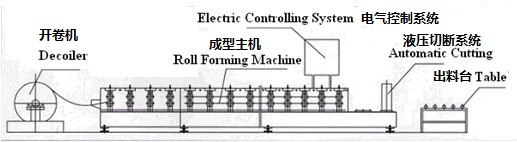

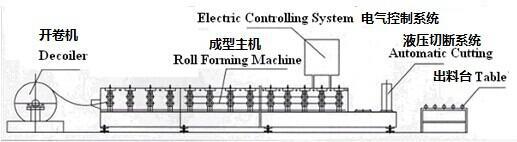

Work Flow of wall angle roll forming machine

| Basic parameters of wall angle roll forming machine | |

| Supported material | Processing material: GI

Material thickness: 0.4-0.8 Material hardness: 550 MPA—350 MPA |

| Working speed | 20m/min |

| Length | about 3000…800…1400 |

| Roller fixer | Guide column |

| Material of rollers | GCr12MoV |

| Number of rollers | 10 rollers |

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

At ZTRFM, various payment terms are acceptable,you can choose what is convenient for you. Also we offer excellent after-sales services. Typically , we offer 1 year warranty and whole life technical support. Our engineers can work overseas and clients can also come to be trained to how to operate machines.

For more information, please contact me at Whatsapp:008618730769688 or send an email to cnzt005@zhongtuocn.com

FAQ

- IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

- HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao toCangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

- WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

- CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

![A)A0L4OE5P[M$P[Q]GV]27N](http://www.rollsformingmachine.com/wp-content/uploads/2015/09/AA0L4OE5PMPQGV27N.jpg)