HG32 welding pipe machine for round pipe, square pipe, oval pipe and others

HG32 machine supports material thickness within 0.4-2.5mm, the diameter range from 10-45mm and the machine speed could make from 30-80m/min.

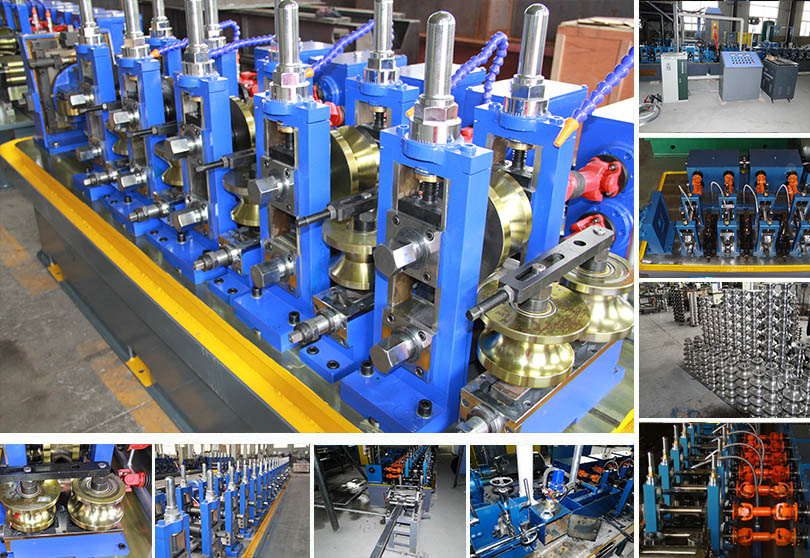

We design this machine as cantilever type, for you can change moulds to make various types pipe easily and quickly. By this kind of you can save 2/3 time when comes to change machine moulds.

For the whole machine, it is easy to install and transport. The machine will be made as a whole, so you do not need to install it complicated. HG32 cantilever type welding pipe machine is good for those who need to make small diameter but with various types decorative pipes.

HG32 welding pipe machine using technology has the following features:

- It supports many kinds of material like carbon steel, steel and others.

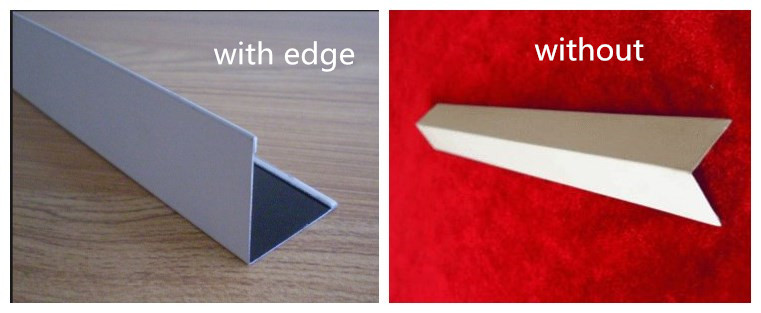

- One machine could make a large range of pipe sizes by changing mold.

- One machine could be used to make square pipe, round pipe by changing mold.

- High working efficiency but low energy consuming. The power is 200KW

- The pipe made by this kind of machine could be used in many areas like water tube, wire pipe and others.

Here are some basic parameters for your reference:

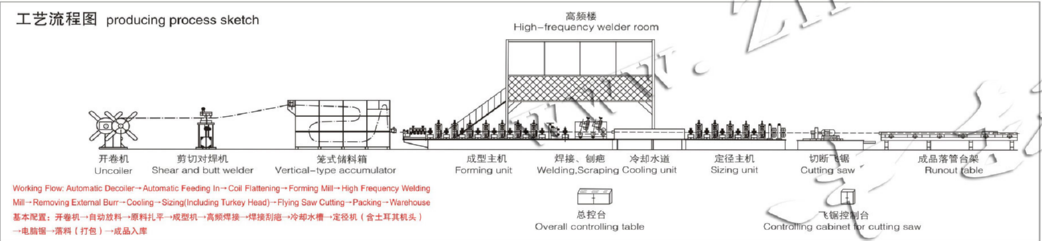

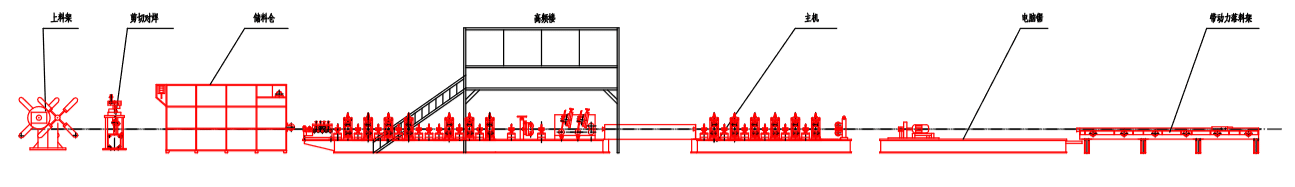

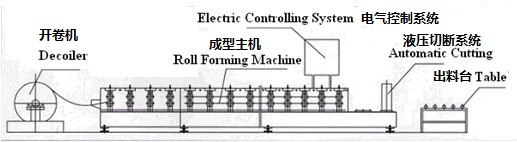

Work flow:

Raw material (steel coil) —- uncoiling —-non-power leveling —-roll forming —-high-frequency welding → removing burrs outside of weld seam —-cooling —-sizing —- cutting —- run-out table

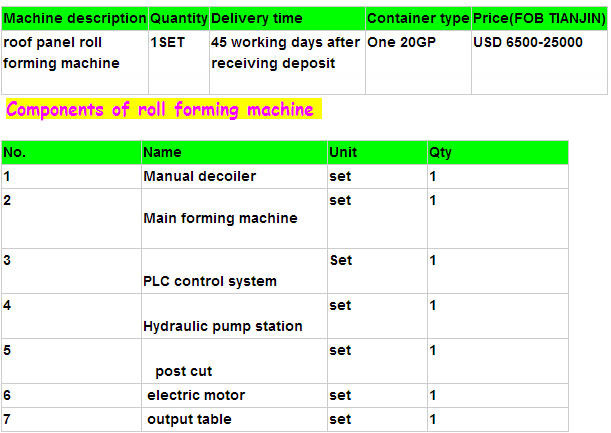

| Main elements | |

| Double head uncoiler | 1 |

| hydraulic shearing and manual welding machine | 1 |

| Coiler feeder to accumulator | 1 |

| spiral accumulator | 1 |

| forming and sizing mill | 1 |

| F5-200kw solid state H.F welder | 1 |

| Electric control system | 1 |

| CNC flying friction saw | 1 |

| Roll out table | 1 |