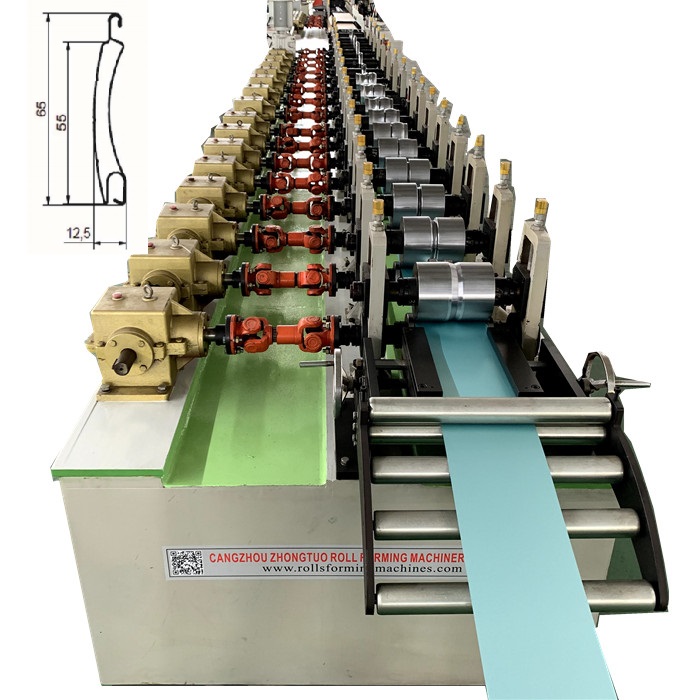

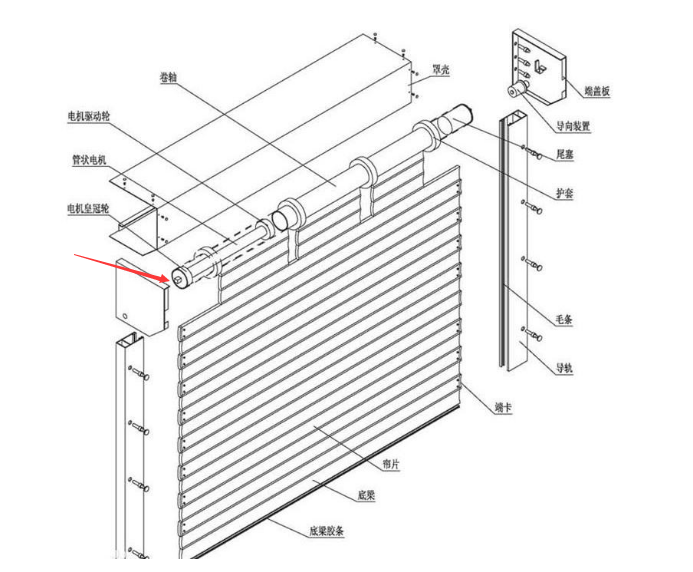

PU shutter door roll forming line Sandwich pu shutter forming line Rolling shutter door machine

Features of a PU Sandwich Panel Line:

– Efficiency: Designs like the 2+2 type can significantly reduce preparation and discharge times, increasing production efficiency.

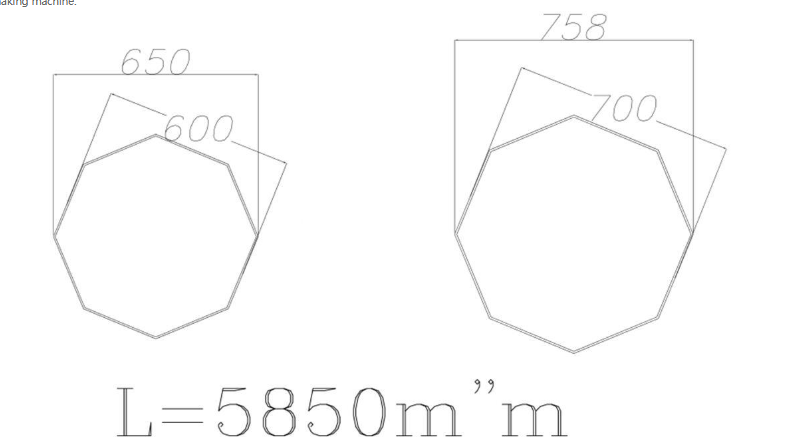

– Versatility: Can accommodate various types of outer layers and core materials, allowing for customization based on specific requirements.

–Environmental Friendliness: Utilizes eco-friendly foaming agents like 141B or cyclopentane instead of harmful CFCs.

– Precision and Quality Control: Ensures accurate measurement and application of materials, contributing to the durability and performance of the final product.

– Worker Safety: Incorporates features that minimize dust and protect worker health during the foaming process.

– User-Friendly Operation: Equipped with HMI (Human-Machine Interface) and PLC (Programmable Logic Controller) for easy operation and monitoring.

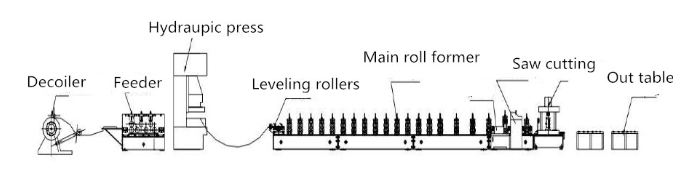

Working Process of a PU Sandwich Panel Line:

Core Material Preparation:The core material, usually polyurethane foam, is prepared and may be pre-cut to size.

Adhesive Application: A suitable adhesive is applied to the core material to bond it with the outer layers.

Layer Joining: The outer layers are attached to the core, and pressure is applied to ensure a strong bond.

Curing: The sandwich panel is cured in an oven, allowing the polyurethane foam to set and harden.

Finishing:The panels are cut to the required dimensions and any finishing touches, such as edge trimming, are applied.

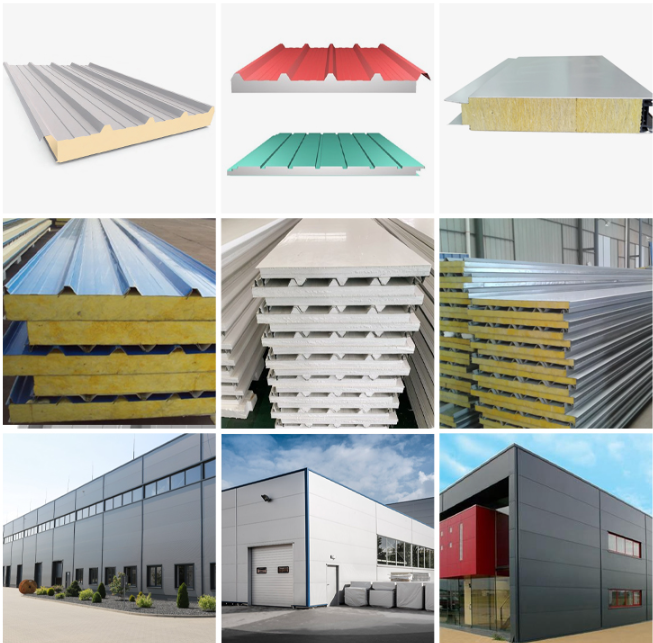

The PU Sandwich Panel Line is a sophisticated piece of equipment that integrates multiple technologies to deliver high-quality, efficient, and versatile sandwich panels for a variety of applications. These panels are prized for their thermal insulation, soundproofing, and fire-retardant properties, making them indispensable in modern construction projects.

PU Sandwich Panel: