Supermarket Storage Rack Panel Roll Forming Machine is Designed to Make the Shelf Back Panel in Batch Fully Automatically

Supermarket Storage Rack Panel Roll Forming Machine

ZTRFM is a leading provider of innovative metal forming machinery, leveraging proprietary technologies to serve manufacturers of shelving and pallet racking systems. Their roll forming machines are widely utilized in the production of pallet rack uprights, step beams, and steel shelving. These components are essential for both OEM manufacturers and custom job shop operations.

For businesses relying on press brakes for low-volume production, ZTRFM offers a streamlined path to roll forming, enabling substantial gains in efficiency and output. With deep engineering expertise, ZTRFM specializes in delivering adaptable solutions that meet the stringent tolerances demanded by today’s shelving and pallet rack applications.

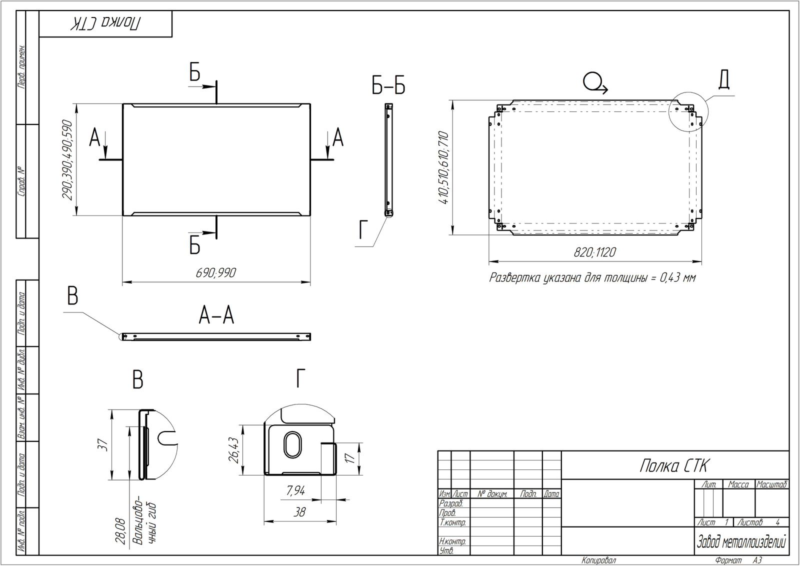

Profile Drawing: Machine Working Flow:

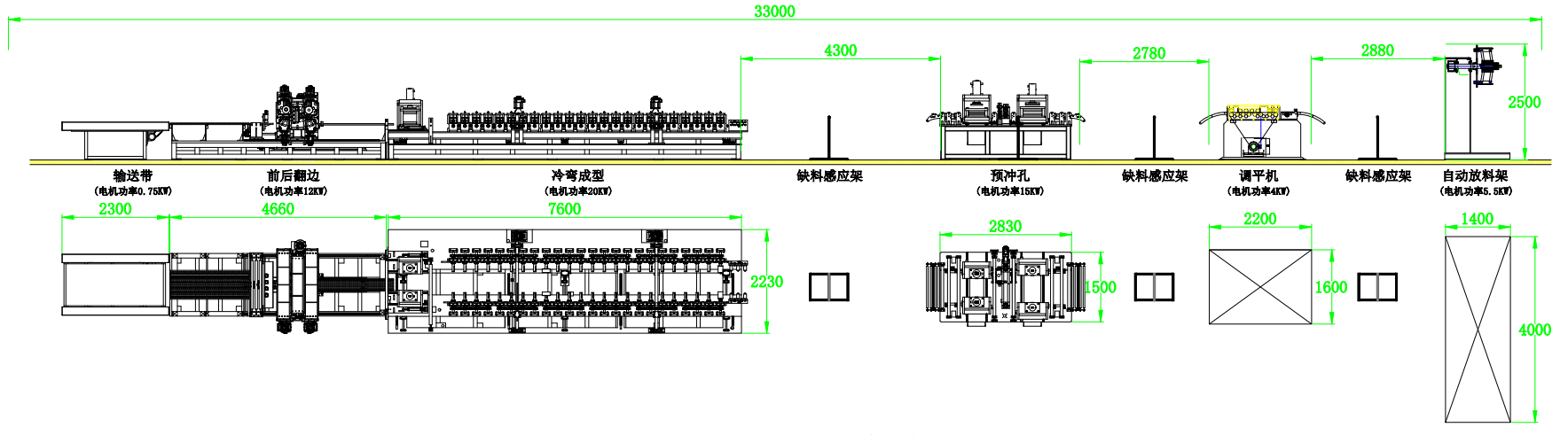

Machine Working Flow:

5T hydraulic decoiler → Leveling machine → 2 hydraulic punching systems (2 sets of molds) → servo feeding → roll forming →Side edges bending →Servo shearing →Servo folding front edge →Folding rear edge →2m receiving table.

Key Advantages of the Complete Line:

1. Fully Servo-Driven System

– The entire line is powered by servo motors, ensuring precise and efficient operation.

2. Adjustable Pre-Punching Width

– The pre-punching width can be fine-tuned using a servo-controlled mechanism for enhanced flexibility.

3.Servo-Powered Roll Former, Cutting, and Flanging

– All major processes, including roll forming, cutting, and flanging, are servo-controlled for consistent accuracy.

4. High-Quality Side Plates

– The main and auxiliary side plates are made from ductile iron castings and CNC-machined in one piece, covering drilling, tapping, and milling.

5. Tapered Bearings for Stability

– The use of tapered bearings ensures straightness and eliminates vibration during operation.

6. Superior Accuracy Compared to Hydraulic Systems

– Unlike competing equipment that uses hydraulic cutting and flanging, which can lead to imprecise positioning, our servo-driven solution offers unparalleled accuracy and reliability.

| ZTFRM Pallet Rack Roll Forming Machine | ||

| Formed Material | Cold rolled coil | Thickness:0.4-0.7mm |

| Panel width | Width range | 410mm 510mm 610mm 710mm |

| Profile | Provide customized,OEM,ODM | |

| Decoiler | capacity:5 tons | Inner diameter:φ450~550mm,outer diameter of the coil material φ 1300mm |

| Roll Forming | Roller station | 20 rows(As your requirement) |

| Diameter of shaft | φ 50mm solid shaft | |

| Material of rollers | Cr12MoV, with vacuum heat treatment, twice tempering, hardness HRC55-58 | |

| Design | Two sets of tapered roller bearings 30209 are equipped on the transmission side, and one set of cylindrical roller shaft NJ209 is equipped on the operation side. |

|

| Cutter | Automatic | cr12mov material, no scratches, no deformation |

| Power | Main Power | ≤ 30 KW |

| Voltage | 380V 50Hz 3Phase | As your requirement |

| Control system | Transmission | Gear transmission |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| Forming Speed | 10 m/min | The speed provide customized |