T Grid Suspension System Main T Cross T Bar White Ceiling Grid Cross Tee Roll Forming Machine

Product Profile Details

The ceiling T-bar roll forming machine is a widely adopted solution for producing T-shaped keels, with thicknesses ranging from 0.3mm to 1.2mm and lengths between 3000mm and 6000mm.

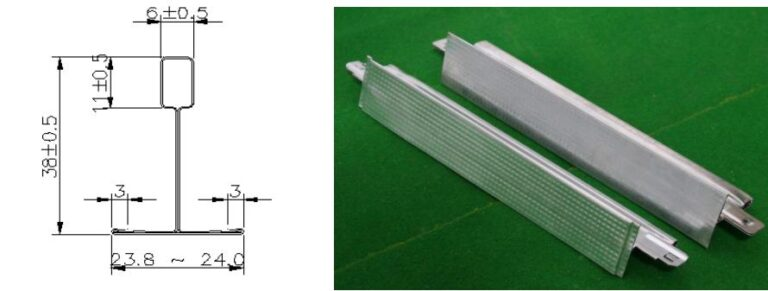

Cross-Sectional Design:

The T-shaped keel has a characteristic “T” profile, typically measuring 24mm in top width and 38mm in bottom width.

Application in Construction:

This material is a key component in building interiors, specifically for suspended ceilings, where it is valued for its durability and adaptability.

Key Features:

– Superior Stability: The unique “T” cross-section enhances support and secures the suspended ceiling structure.

Metal Framing Applications:

Metal framing components used in concealed grid gypsum ceilings for lightweight structures include furring channels, carrying channels, studs, tracks, wall angles, and main frame channels.

Drywall Ceiling Channel Production:

The ceiling/drywall/furring/C-line roll forming machine is engineered for producing drywall ceiling channels (also referred to as C-line, furring channels, or drywall frames). With a robust structure and customizable design, it operates at speeds up to 35m/min to deliver consistent performance.

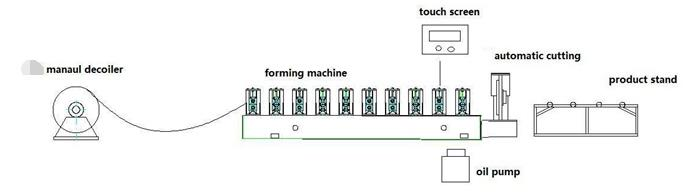

T-Bar and T-Grid Production Line Components:

1. Decoilers

2. Main roll forming machine

3. Automatic hydraulic cutting station

4. Hydraulic cooling system

5. Electric control system

Key Specifications:

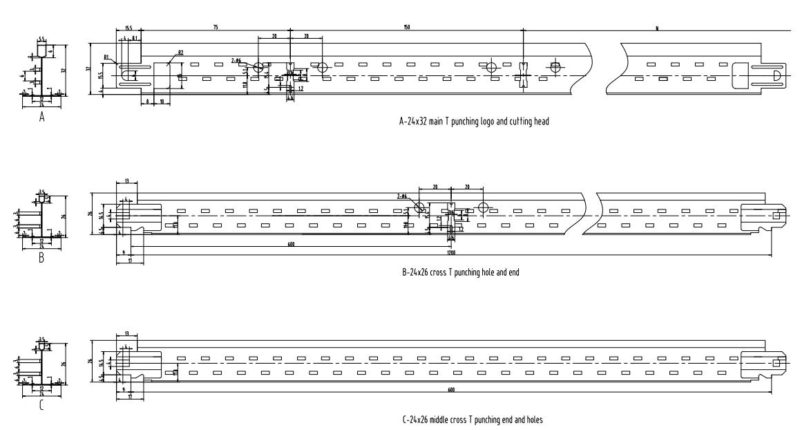

– Main Tee Bar: H38×24mm, H32×24mm; Length: 3600mm; Thickness: 0.20–0.40mm

– Cross Tee Bar: H26×24mm, H24×23mm; Length: 1200mm, 600mm; Thickness: 0.20–0.40mm

Additional Capabilities:

ZTRFM offers fully automated metal ceiling tile production lines capable of manufacturing ceiling panels in various sizes, such as 600×600mm, 300×300mm, and 600×1200mm. These metal ceiling tiles integrate seamlessly into exposed ceiling suspension systems.

Impeccable Performance at Any Speed:

ZTRFM roll forming systems are designed for precision and efficiency, providing tailored solutions for manufacturing T-bars (main runners and cross tees) to support suspended ceiling panels. Available in different configurations, these systems cater to varying profile requirements, output demands, and automation levels.

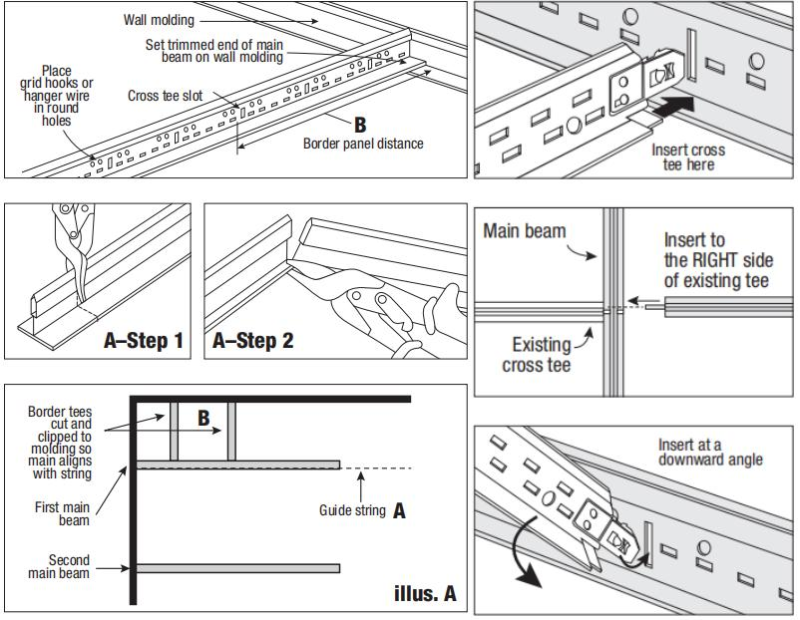

Installation of Suspended Ceilings:

This method is ideal for setups requiring easy access to overhead utilities like wiring, ducts, or piping. ZTRFM’s roll forming technology ensures flawless profiles and connectors, enabling reliable and efficient suspended ceiling installations.

The Technical Specifications Of The Ceiling T grid Machine:

| ZTRFM Ceiling T grid Machine | ||

| 1.Formed Material | GI | Thickness:0.15-0.4mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 18 rows for the main T

16 roller station for the cross T bar |

| Diameter of shaft | 50 mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 6T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW*2 sets |

| Hydraulic system power | 7.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | Max 35m/min(customized) | Speed is adjustable according to customer’s request |

More pictures of the machine: