IBR Metal Steel Roof Tile Forming Machine

IBR Metal Steel Roof Tile Forming Machine

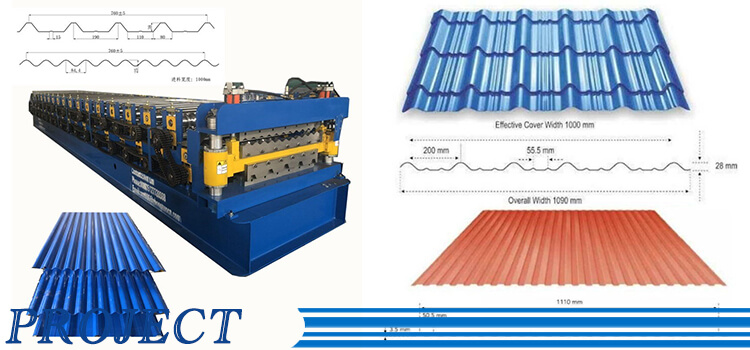

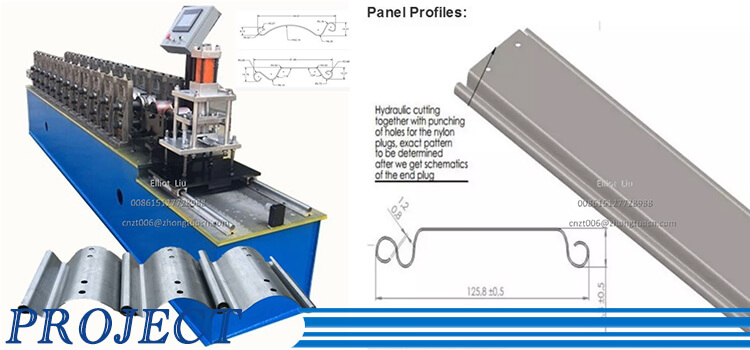

Generally speaking, an IBR sheet roll forming machine can easily produce the metal roofing sheets at the speed of 25 meters to 50 meters per minute with Inverted Box Ribs. IBR metal sheet roll forming machine enjoys advanced PLC control system & Omron encoder and is capable to run both automatically and manually.

What is IBR panel sheet?

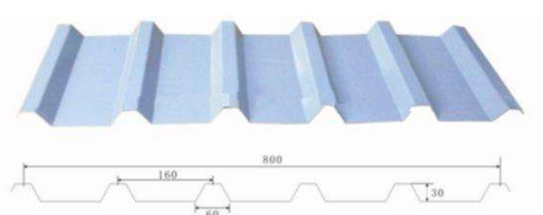

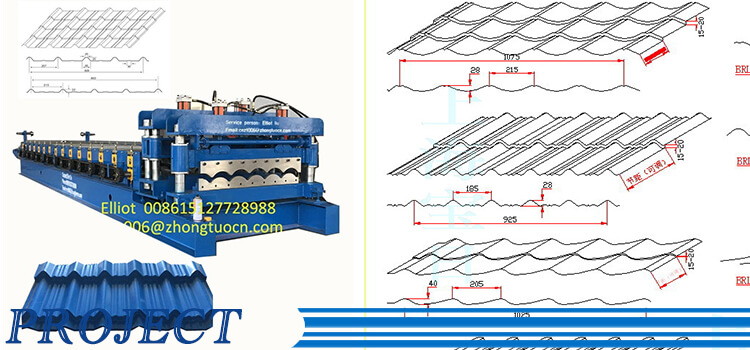

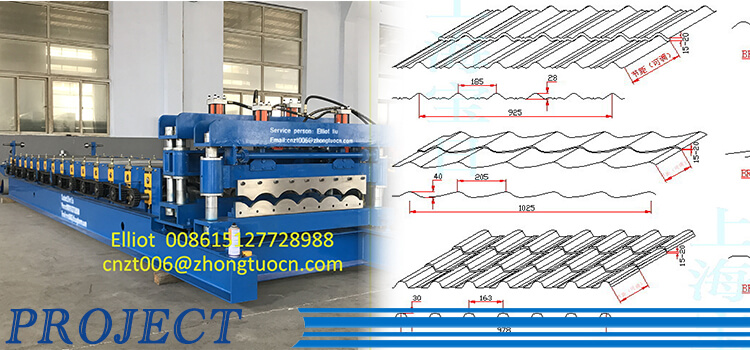

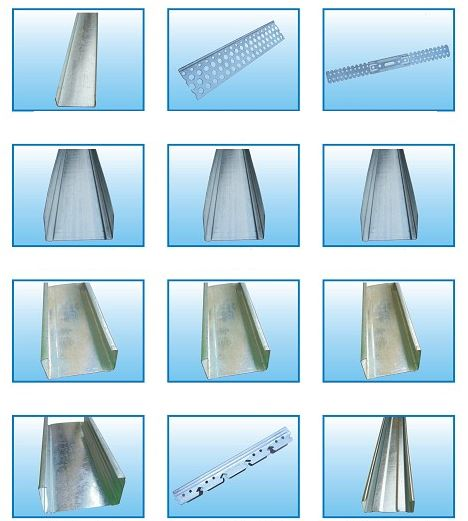

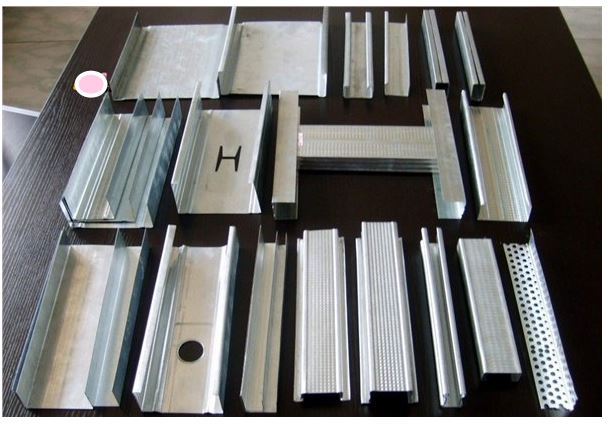

IBR, abbreviated from “Inverted Box Rib”, usually applies to outside cladding or roofing materials in commercial, industrial and residential buildings. Besides, the raw material is mostly Galvanized steel with thickness stretching from 0.4mm-0.8mm, and the width between 925mm and 1,219mm. Sometimes customers also employs PPGI and the thickness also could be from 0.18 to 0.2mm if the customer uses SG550 hardness strong material. IBR roofing roll forming machine and corrugated sheet roll forming machine are TOP 10 metal roofing rollformers in African steel building industry.

Based on the IBR sheet features, we design machine like following:

Technical Specifications of 686 IBR for Example Sheet Roll Forming Machine:

1.Uncoiler: Manual Uncoiler or you can choose hydraulic decoiler

2.Inner diameter: 508mm

3.Outer diameter: 1250mm.

4.Loading weight: 5 tons or 10 Ton

5.Forming speed: 12m/min.to 50 m/min

6.Forming steps: 16 stations

7.Material of Shafts: 45# high-quality steel

8.Diameter of Shafts: 70mm

9.Material of Roller: high quality 45#steel coated with hard chrome 0.05mm.

10.Thickness of Siding Plate:25mm

11.Transmission: chains-sprockets or gearbox

12.Motor Power: 15 KW

13.Material of cutting blade: Cr12 with quenched treatment 60-62

14.Hydraulic Power: 4 KW

15.Panasonic PLC Control system, touch screen, frequency converter

16.Voltage 380V/50HZ/3phase or customize

The following part is about the details of the IBR machine:

1.For the gear it is important for the machine we use Chinese famous brand HRB

2.For the leveling part, we will use two layer and handrail adjustment.

3.For the roller we use the carefully polishing to make sure it will not damge the surface of raw material.

The main parts of the IBR roof panel roll forming machine is composed by the following elements:

Manual Uncoiler;

Feeding Guider;

Roll forming machine;

Hydraulic Cutting system;

PLC Control System;

Run-out Table

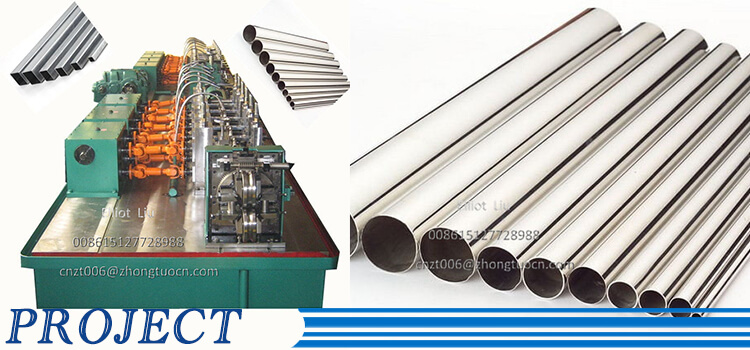

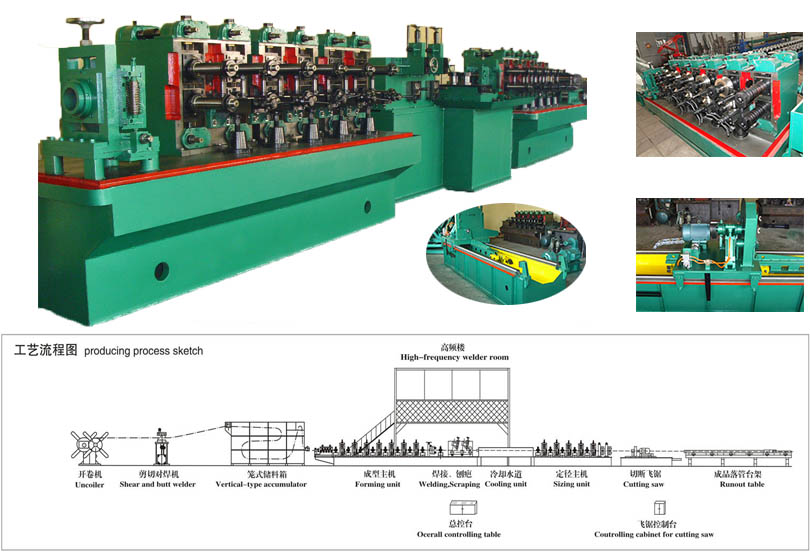

For the IBR roofing machine above is about the slow speed like 25 meter per minute. We also have another options like 45 meter per minute, and here is the machine pictures for your reference:

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.