1.0–3mm embosser machine, Checkered Plate Embossing Machinechequered steel plate embossing machine

The sheet produced by the sheet metal embossing machine is non-slip, engraved and rolled into a leaf shape, and can also be rolled with your favorite pattern according to your requirements. sheet metal embossing machine can be customized according to your needs.

If you are interest or need this machine, please contact me.

Applications

The embossing machine is designed to create patterns using an upper and lower roller. We will customize the machine based on the width of your coil or metal sheet, the type of raw material, thickness, and any other specific requirements. If you have particular needs for embossing depth, we can accommodate those as well. Regarding patterns, you can provide your own design, or we can suggest some common options for you to consider.

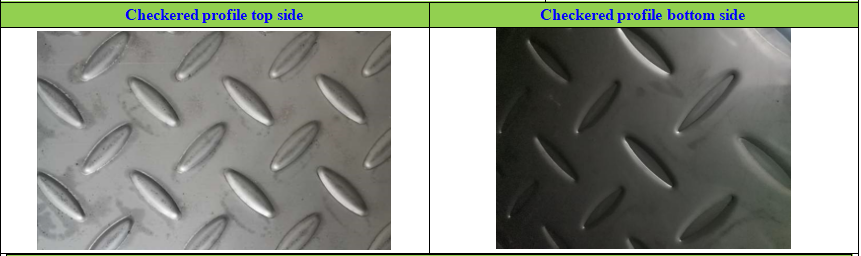

Our steel plate embossing machines are primarily designed for producing anti-skid checkered steel and aluminum plates or foils. They can also be used for embossing leather, fabric, and sponge materials. The patterns can be customized according to the customer’s specifications, and the thickness of the metal plates can vary based on their intended use.

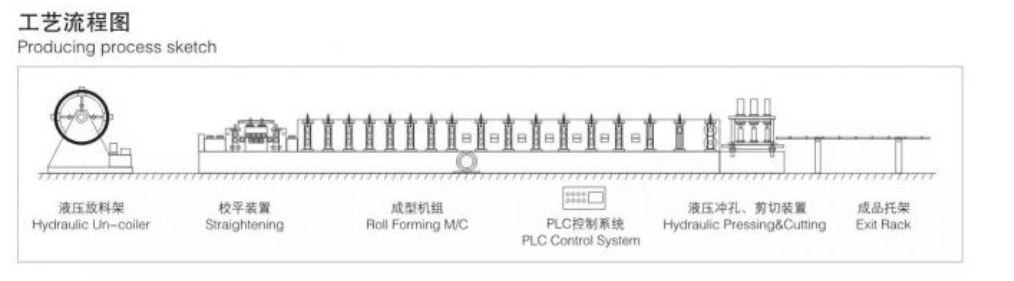

Recently, checkered plates have found widespread application in architectural decoration, air conditioning, packaging, electrical products, and various other fields. We offer steel plate embossing machines suitable for both single plates and metal coils, utilizing setups such as Uncoiling the sheet – Infeed guiding – embossing – Rectifying the straightness – Measure length – Cutting the panel – automatic stacker

Steel plate embossing machine Pattern:

Embossing Machine working flow:

Uncoiling the sheet – Infeed guiding – embossing – Rectifying the straightness – Measure length – Cutting the panel – automatic stacker

Technical parameters |

||

| Series | Details | Parameter |

|

Product sheet |

Raw material | GI/PPGI/CR/HR/SS |

| Material thickness | 1.0-3.0 mm | |

| Feeding width | ≤1250 mm | |

| Sheet cutting length | Adjustable | |

| Part 1 Input coil supporting table | ||

| Usage: when feeding coil, as the material thickness up to 3.0mm, it will be quite heavy, by this device we can feed coil easily and to the right direction. | ||

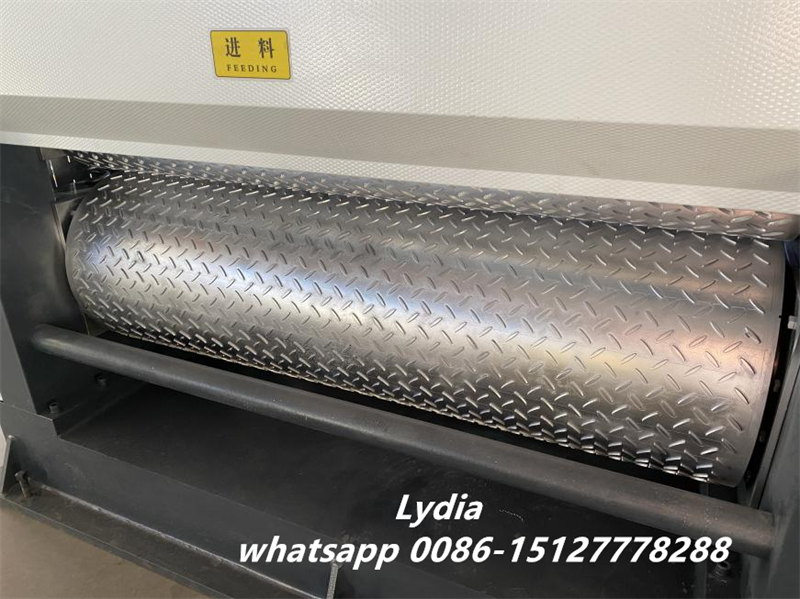

Part 2 Metal embossing machine |

||

| Remark | 1. The two rollers of the embossing machine : solid and forged, 42crmo alloy steel, heat-treated, hard degree HRC55°— 60°. 2. The diameter of the embossing roller:450mm×1400mm, 3.The working thickness of the pressing plate : 0.8mm-3mm. 4.The depth of the pattern :3.0mm 5.the height of the engraved: 2.0mm. (The pattern is tear drop pattern.) 6..the national standard motor power : 11 kw, 7.The working speed : 8m/min. 8. weight :9 tons. |

|

Part 3 Leveling and receiving table |

||

| 1. Leveling rolls: Ø120*1400mm*11 pcs, machine weight around 2.5 Ton.

2. Drive: 4 kw motor 3. Pressure type:screw with worm reducer WPWKO 70 4. Embossing speed: 0-8m/min speed adjustable 5. Electric control: Fuling AC frequency driver |

||

| Machine structure

1. Stand: 110mm solid steel plate 2. Bearings: 3003140 Ø200 x Ø310 x 90mm, 4pcs 3. Bearing seats: Ø420 x Ø450 x 150mm, 4pcs 4. The gear of matching upper embossed roller and lower embossed roller has fine adjusting function. 5. Include: Input and output platform Safety cover 6. Gear coupling Gear material: 42CrMo |

Electric control system

1. Controller: button controller 2. Frequency Converter: Delta 3. Motor: China famous brand 4. Contactor: CHNT, China |

|