standing seam roof panel roll forming machine

The standing seam roof panel is widely installed on residential and light commercial roofing projects with great success. this type of standing seam metal roofing look great and add much curb appeal to a building.

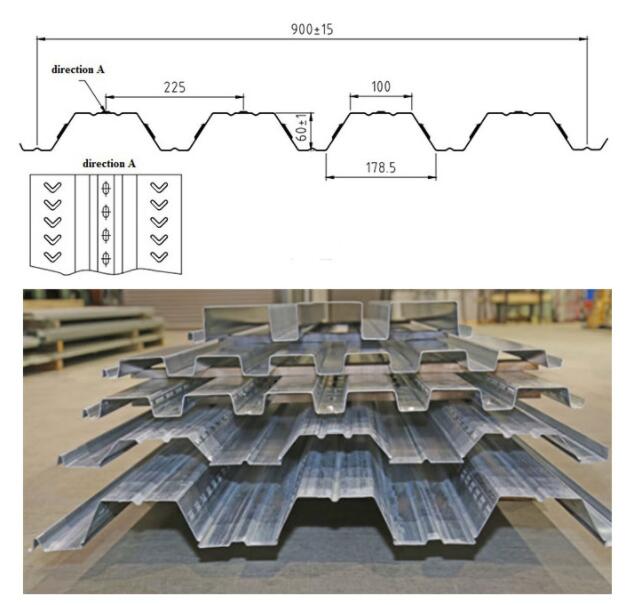

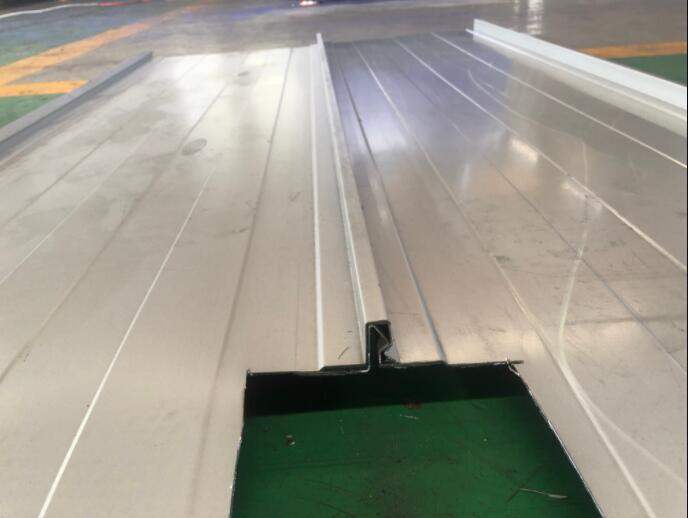

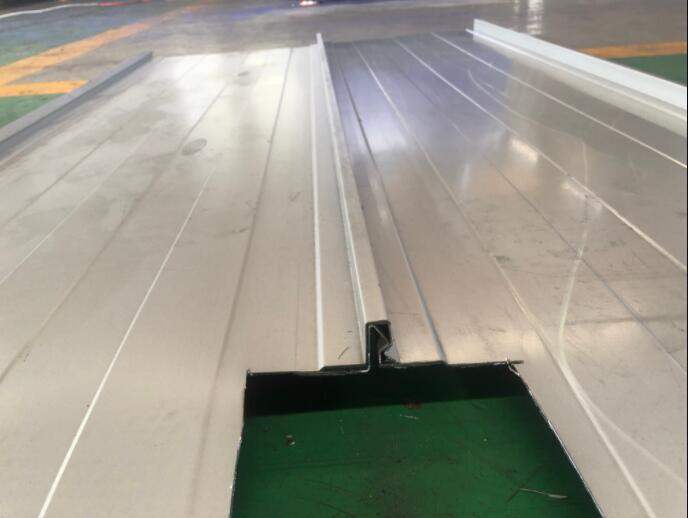

here are photos of finished good quality standing seam roof panels:

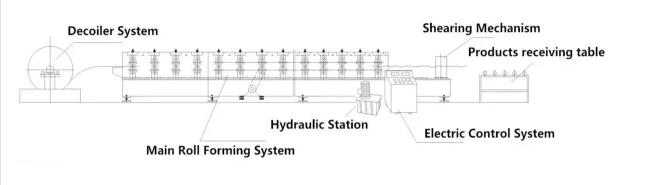

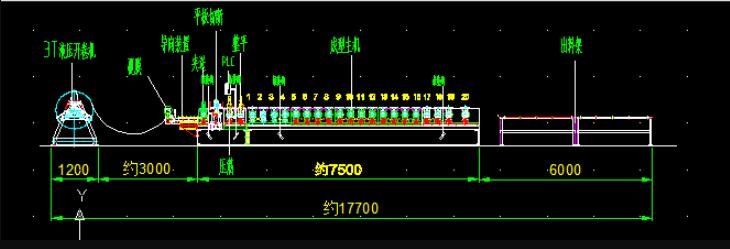

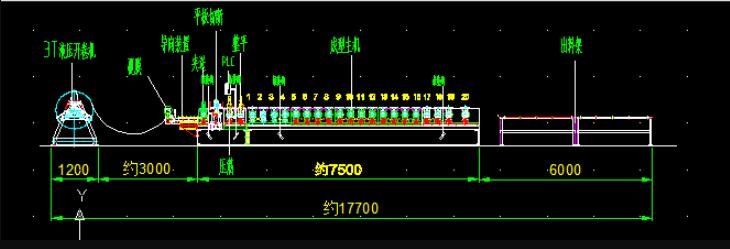

The working flow of standing seam roof panel roll forming machine:

Main components of standing seam roof panel roll forming machine

| No. |

Name |

Unit |

Quantity |

| 1 |

3T decoiler |

set |

1 |

| 2 |

Feeding,pinch, and pre-cutter part |

set |

1 |

| 3 |

Embossing roller(optional) |

set |

1 |

| 4 |

Head roller |

set |

1 |

| 5 |

Roll forming part |

set |

1 |

| 6 |

Product run-out table |

set |

1 |

| 7 |

PLC control station |

set |

1 |

| 8 |

Hydraulic oil pump station |

set |

1 |

| 9 |

Spare parts |

set |

1 |

The following is detailed introduction of each main elements of this snap lock standing seam profile roll forming machine:

1) decoil of standing seam roof panel roll forming machine :

Usage:It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity:3T

Uncoiling width:610mm (slitted from 1220mm coil)

Inner diameter: 450-550mm

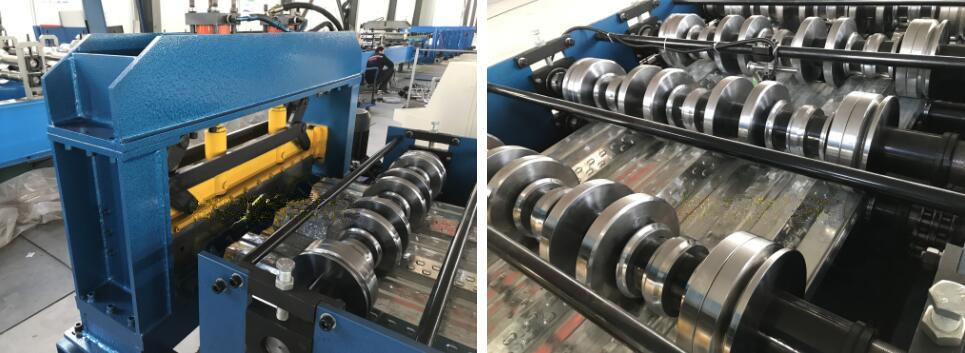

2)feeding,pinch and pre-cutter of standing seam roof panel roll forming machine

we adopt pre-cutting for this snap lock standing seam profile roll forming machine, in order to higher working speed, and also suitable for different feeding width

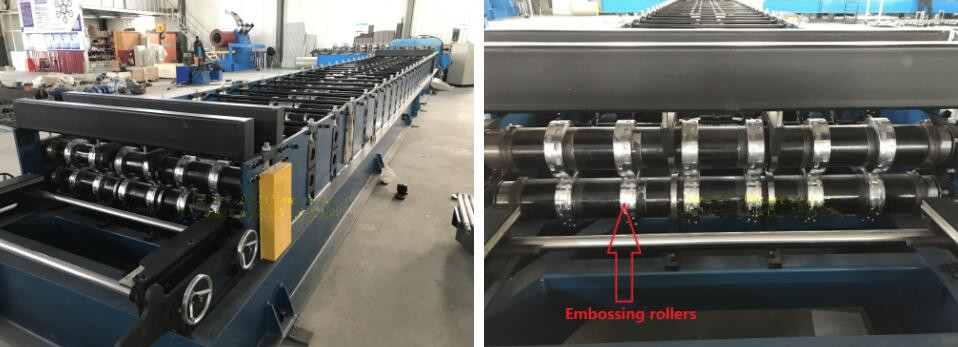

3)main roll forming part of standing seam roof panel roll forming machine

Length of the main part:about 7200*1450*1500mm

Weight of main part:6-7T

Voltage:380V/50HZ 3Phase

Roller fixer:middle plate

Frame:350H steel

Drive mode:chain

Material of rollers:45#steel, surface hard chromium plating

Material of shafts:45#steel

Diameter of shafts: φ 70mm

Number of rollers: 20 rollering stations

Main power:7.5kw

Material of mould:Cr12 quenched

Power supply:hydraulic power