Argentina warehouse storage shelf rack roll forming machine pillar rack making machine

Description of Upright rack Roll Forming Machine

The Goods Shelf Roll Forming Machine, which includes both shelf and pallet rack roll forming machines, is designed for versatile storage solutions. Pallet racks can accommodate a wide range of goods, from small-quantity, multi-variety items to large-quantity, uniform products. Typically, the machine handles materials up to 2.5mm in thickness and operates at speeds between 15-25 meters per minute. It is particularly well-suited for use in tall warehouses, offering efficient storage and organization capabilities.

Main features of the rack upright forming machine include:

- Shelf racks are produced with high precision, within 1mm tolerance.

- Built with a sturdy underframe using 82mm solid shafts and H-shaped steel, ensuring long-term production without machine deformation.

- CNC-machined rollers guarantee rack accuracy.

- Stress-relieved cut and punch frames prevent deformation during extended use, keeping racks smooth.

- Equipped with Mitsubishi or Siemens systems for stable, easy operation. Once length and quantity are set, the machine auto-produces racks with a cutting tolerance of ±2mm.

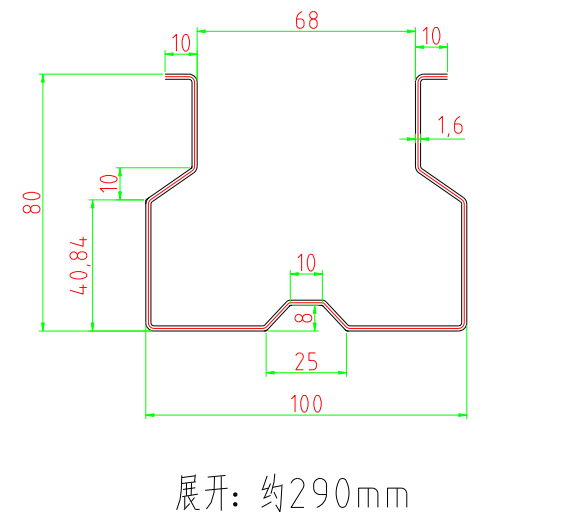

Profile Drawing:

Typical Applications:

Pallet rack uprights enable shelf levels to be adjusted in two-inch increments. The front-facing teardrop perforations are designed to connect pallet rack beams securely.

ZTRFM provides various types of racking upright machines, allowing you to customize your pallet racking by selecting the frame height and depth. Each bolted teardrop upright comes preassembled with components such as posts, diagonal struts, and foot plates, making it easier to assemble your shelving system.

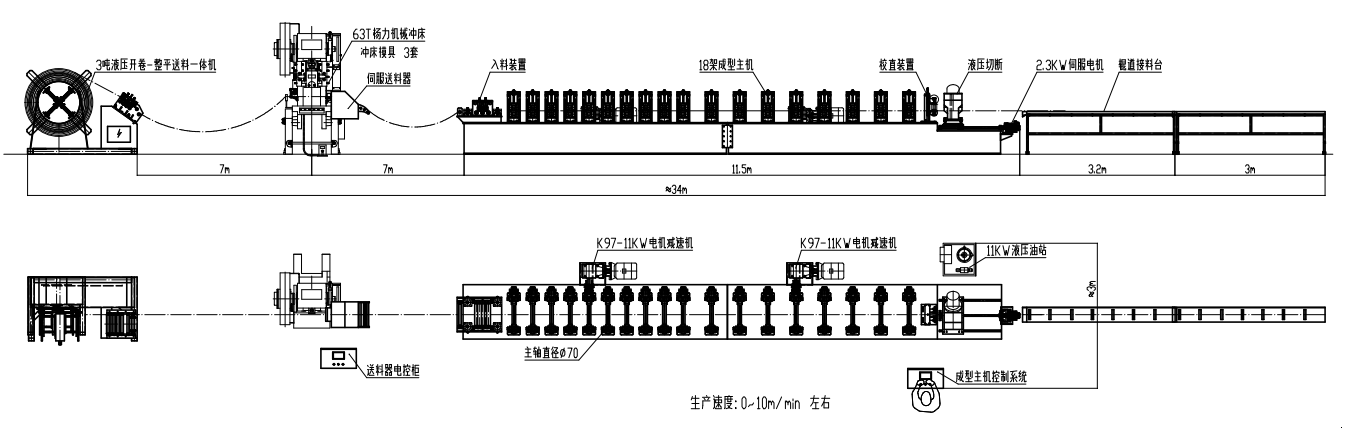

Upright rack Roll Forming Machine working flow:

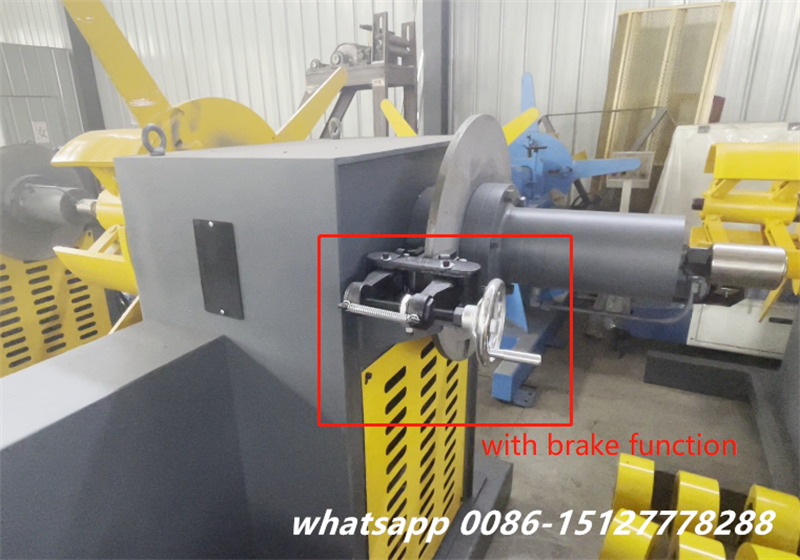

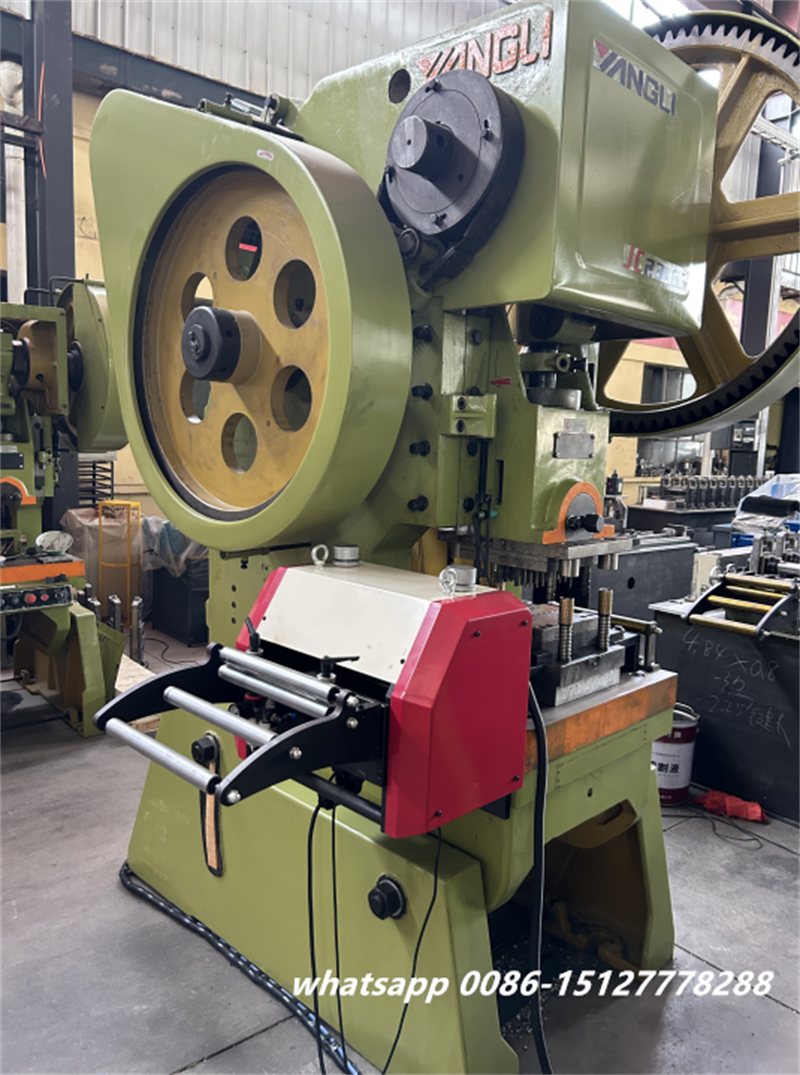

Active Uncoiler – High Precision Punch Feeder – High Speed Punching Press (Including Die)- Precision Col Rolling Forming Machine – CNC Shear – Receiving Rack.

The Technical Specifications Of the Upright rack Roll Forming Machine Rolling Forming Machine:

|

Upright rack forming machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 1-2 mm | ||

| Decoiler | Roller station | 7 rollers | The standard one to match the production line |

| upper 3 + down 4 to level the coil. | |||

| Loading capacity | 3 Tons | ||

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 70 mm | ||

| Roller material | Cr12 HRC 56-58 | ||

| Rolling station | 18 stations | ||

| Work speed | 0-12 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Work power | 11 kw+11 kw (two motors driving) | ||

| Transmission | Chain transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

More pictures of the machine: