Metal Load Bearing Stud Framing System (Heavy Gauge) Steel Roll Forming Machine PLC Control System

Metal Load Bearing Stud Framing System (Heavy Gauge) Steel Roll Forming Machine PLC Control System

Description of Load Bearing Stud Framing System (Heavy Gauge) Roll Forming Machine

ZTFRM provides a comprehensive range of structural framing components and accessories, with thicknesses ranging from 20 gauge to a maximum of 10 gauge (118 mil). Their complete line of studs, joists, and track systems complies with ASTM, ICC, and UL standards. ZTFRM Products employs advanced technologies and engineering techniques in light frame manufacturing to ensure that their products meet industry benchmarks for performance, strength, safety, and functionality.

ZTFRM offers a range of studs with various flange widths designed for diverse applications. You can easily find the system you need using the ZTFRM iTools – Structural Stud Lookup Tool.

Flange sizes available are 1-3/8”, 1-5/8”, 2”, 2-1/2”, and 3”. Thickness options include 33 mils (20ga), 43 mils (18ga), 54 mils (16ga), 68 mils (14ga), and 97 mils (12ga). Additional member depths of 7-1/4″, 9-1/4″, 11-1/2″, 13-1/2″, and 14″ can also be supplied.

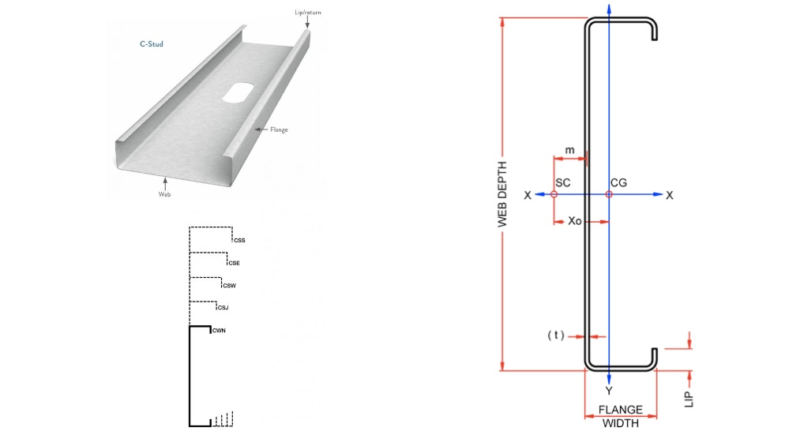

Profile drawing:

Applications of Structural Metal Framing include:

– Exterior lateral load-bearing curtain walls

– Axial load-bearing exterior walls

– Interior load-bearing walls

– Rafters, purlins, and girts

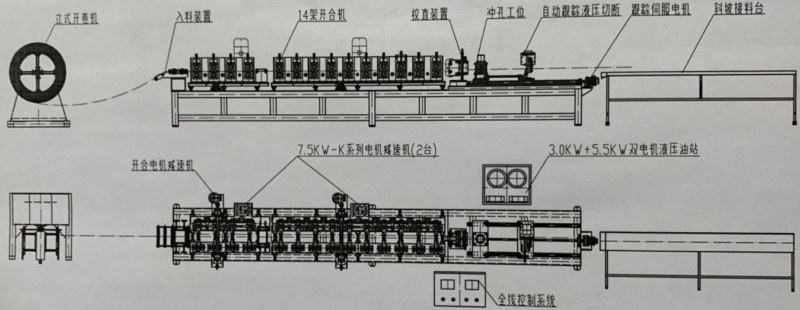

Load Bearing Stud Framing System (Heavy Gauge) Roll Forming Machine working flow:

The Technical Specifications Of The Load Bearing Stud Framing System (Heavy Gauge) Rolling Forming Machine:

| Load Bearing Stud Framing System (Heavy Gauge) rolling forming machine | ||

| 1.Material of coil | Material Thickness | 0.4-0.9mm galvanized sheet full hard 85-95, G550, PPGI |

| 2.Forming system | Rolling Speed | 0-40m/min( without the cutting time) |

| 3.Main body

|

Roller Stations | About 14 stations |

| Roller Material | 45# Steel with quenching 60mm shaft | |

| Maim Motor Power | 7.5 kw | |

| Hydraulic cutting Power | 8.5 kw | |

| Bearing | Rubber sealing bearing | |

| Material Of Cutting | CR12 with quench treatment | |

| Hardness | HRB 85-95 | |

| Tolerance | +-1.5mm | |

| 4.Cutter | Cutting way | Stop cutting |

| 5.Voltage | Electric Source | 380V 50Hz 3Phase

Also can satisfy Customer’s require |

| 6.Control system | Control System | PLC Delta |

| Inverter | Yaskawa | |

| Weight | About 2.5 tons | |

| Way Of Drive | 1 inch single chain | |

| MOTOR | Under the frame of the machine | |

More pictures of the machine: