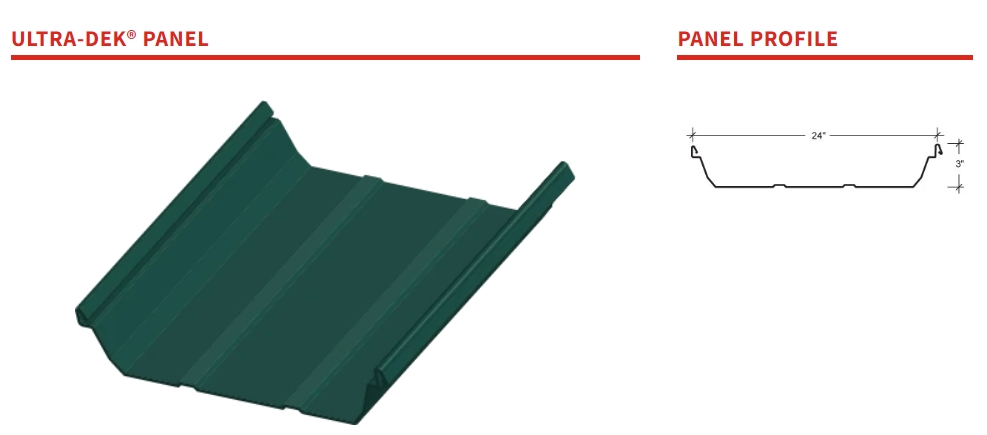

Trapezoidal leg standing seams roof panel roll forming machine Ultra Deck roll former

Ultra-Dek® metal roof panels feature snap-together, trapezoidal leg standing seams roof system that carries Air Leakage and Water Penetration testing approvals. This roof system is commonly used for industrial, commercial and architectural applications and can be erected on various types of construction. Ultra-Dek® panels are available in 18-inch and 24-inch widths. Ultra-Deck requires a minimum slope of ¼:12 and is ideal for industrial, commercial and architectural applications. Ultra-Deck can be erected on various types of construction.

| Part 2: Main Details of standing seams roof panel roll forming machine | ||||

| Roll forming machine | Feeding device | Steel plate welded as the feeding platform | ||

| One set guiding roller | ||||

|

Rolling shaft |

Shaft material:45# STEEL | |||

| Shaft type: solid shaft | ||||

| Shaft diameter: 60 mm | ||||

| Tempering treatment to prevent deformed and improve hardness | ||||

| Roller | 45# steel with hard chrome coating | |||

| Rolling station | 16 rolling stations | |||

| Work speed | 0-15 m/min | |||

| Machine structure | Carbon steel welded structure | |||

| Machine basic frame | 350# H steel welded | |||

| Anti rusty treatment after welding | ||||

| Work power | 5.5 kw | |||

| Part 3: PLC control system of standing seams roof panel roll forming machine | ||||

| Control system | Frequency brand | Delta (original) | ||

| PLC brand | Delta (original) | |||

| Frequency brand | Delta (original) | |||

| Screen type | Touch screen, also have buttons on the panel | |||

| Screen language | English/Chinese/Spanish | |||

| Cut command | Yes | |||

| Profile length set-up | Yes | |||

| Batch quantity program | Yes | |||

| Low pressure electric part | Schneider brand | |||

| Encode | Omron brand | |||

|

||||

| The control panel with multi order input | ||||

|

||||

| Part 4: Hydraulic cutting system | ||||

| Hydraulic system | Work type | Hydraulic cutting | ||

| Driving method | By pillar type Cylinder | |||

| Hydraulic motor power | 3 kw | |||

| Cutter material | GB-Cr12 | |||

| Cutting length tolerance | ±1mm/3m | |||

| Cutting feature | Steady and safe working condition | |||