Metal Ceiling T Grid roll forming machine

Zhongtuo Cold Roll Forming Machinery focusing on Suspension Ceiling T Bar/T Grid Roll Forming Machinery;

Roller and Mould/Die Material and Processing and Heat treatment we do by our own;

Electric control Cabinet and PLC by our own Electric engineer with Superb Performance ;

The Most Automatic, Advanced and Fast Speed while Stable performance;

Fully Automatic Non-stop Flying Cutting off;

Worm Gearbox Reducer Transmission;

Stitching Mould and Patented Steel head Clip Lock Continous Mould;

Perfect service and High standard QC;

Fire-proof Hole and Custmer’s Logo on T Bar;

Lifetime QWP (quick weary parts) support and Technology upgrade service.

Product size: H*W(MM)38×35; 38×24; 38×15; 32×24; 32×15; 28×24; 28×15 etc. Length: 3600/3660mm

Any size and any demand we can do as per customer’s drawing or sample.

Main Components(A—-F):

A(2 Uncoilers for GI& PPGI) + B(Main Machine Roll Former) + C(Automatic Punching& Cutting-off System) +D(Electric PLC control Cabinet) + E(2 Hydraulic standions) + F(Run-out Table)

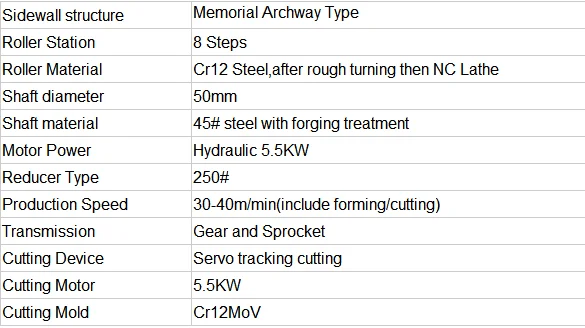

Main Parameter:

Stations: 18-24 Stations

Speed: 20–25M/Min(6–7Pcs/Min)

Total Power: 21.2KW(4KW+2.2KW+15KW)

PLC brand: Siemens

Human-Machine interface: Siemens

Installation length: 14.8M

Die/Mould Material: SKD11

Customer’s Logo: Ok

Anti-Fire Hole: OK

Stitching Line: Ok

Steel Head Lock: Ok

Transmission: Worm Gearbox Reducer

Main Hydraulic station with Accumulator for stable and precise performance

A: Uncoiler/Decoiler/Coil Opener/Raw Material Shelf:

Code: MT-200;

Weight: 100kg;

Size: 1000*800*1100(mm)

Raw Material Roll :

Inner Diameter: 450-530mm

Outer Diameter: 1200mm

Loading weight: 1000kg

Make sure the GI and PPGI

Unoiler in the exact line with

Main Former Machine

Station/Pass/Pinion: 18 stations

Speed: 20—25M/Min(6–7Pcs/Min)

Machine body: Carbon Steel, Thickness 20mm, Polished, Rust Prevention Paint Protection,Any color available

Transmission: Motor 4KW, Main Transmission: Chain Drive, Between Rollers: Worm wheel Gearbox

Stitch: Four Rollers real stitch, can also be used for fake stitch.

Side plate: Thickness 30mm, Polish 6 sides, high precision boring

Principal Axis: 45# steel, tempering heat treatment, mill grinder precise making

Electric Cabinet: SIENENS PLC programmed, Touch Screen, FullY Automatic controlling system.

Punching Die: Material D11, Hardness HRC 58-60, Precise milled, precise making, easy to removable parts.

Stitching Mechanism

Roller: Material Cr12 Inner diameter 39mm, Min OD 90mm, HRC 55-56, Symmetry in the range of 0.05mm

C Automatic Punching and Flying Cutting-off System:

Features:

Punching Die: 24 sets( 2 head locks 22 Main Tee holes)

Anti-Fire Hole Die Available on Machine

Cutting: Flying Cutting-Off Contineous working non-stop

Driving Force: 2 Hydraulic stations one for Punching mechanism travel and one for punching

Accurancy: Height and Width within 0.1mm; In Length 0.3mm/Meter

Die Material: 45# steel and Cr12MoV, Heat treatment Vacuum 58–60HRC

Cutting off Length: 3600 or 3660mm

Hole Distance: 150cm or 6″

Custom Logo Punching at same time on Machine Fully Automatic

D Electric PLC control Cabinet

Features:

PLC brand: SIEMENS

Human-Machine Interface: SIEMENS

Inverter: Teco Taiwan brand

Switch Power: Delta Taiwan brand

Wire connection interface: Aviation plug

E Hydraulic stations

Features:

Hydraulic brand: LYHP

Electromagnetic valve: HUADE brand

Accumulator: Nitrogen

Main Hydraulic: 15KW

Secondary Hydraulic: 2.2KW

Color: Any color available

F Run-out Table

Features:

Size: 3800x750x970mm

Finish: polish

Material: Stainless Steel 304 the outward surface painted protection, Any color available

This compenent is working desk. Product will drop onto the table and slide out smoothly, so it avoids scratching and easy for packing. And there are waste grooves upgrade to conduct the waste steel odd ends to the barrel.

If you what to know more information about Half Automatic Tee Bar Roll Forming Machine ,you can contact us anitime.

Our Email is ceo@zhongtuocn.com