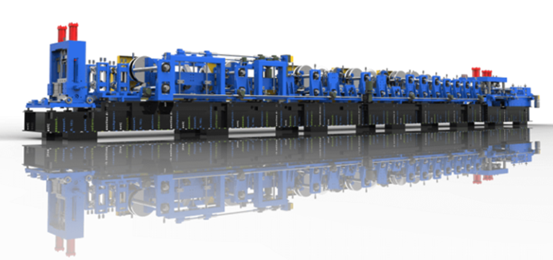

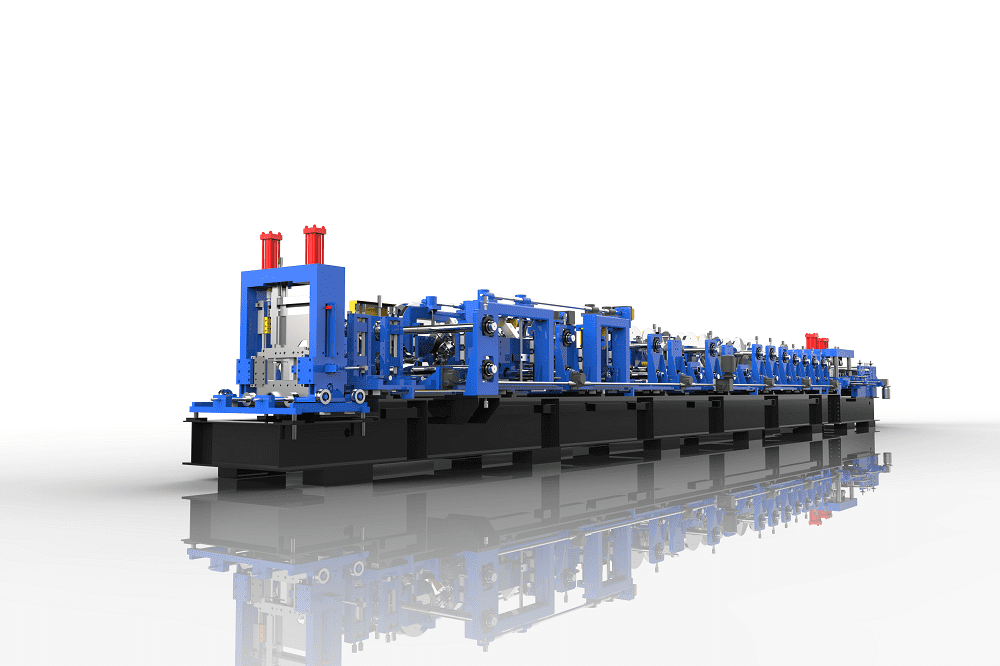

ZTRFM Top Hat Section Cold Roll Forming Machine Omega Purlin Roll Former

High-Speed Top Hat Section Roll Forming Machine with Servo Flying Cutoff

This machine, exported to Canada, is expertly designed to manufacture steel top hat sections tailored to client specifications. By utilizing the Hat Section Cold Roll Forming Machine, profiles are created with high precision and production speeds reaching up to 15 meters per minute.

The line is controlled by an advanced PLC system, allowing operators to easily input production details such as hole distances and cutting lengths through a touchscreen interface. Once programmed, the machine, including features from the Omega Purlin Roll Former, operates automatically and halts after completing the assigned production.

Machine Advantages

Durable, Stable, and Safe

- Durable: The machine base is constructed from high-quality H-beam steel for robust performance.

- Stable: Powered by a 7.5KW motor, ensuring smooth and steady operation.

- Safe: Key risk areas are marked with yellow warnings, and protective mesh covers enhance operator safety.

Machine Specifications

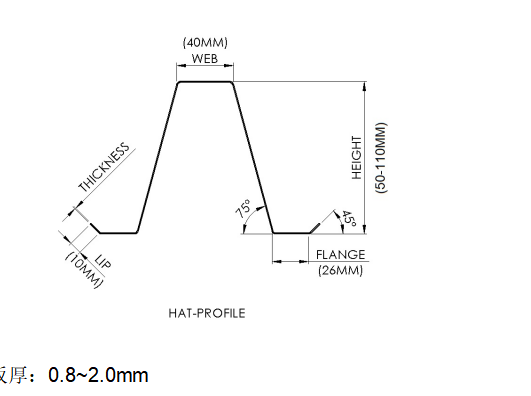

Parameter Details Profile Shape C Shape Profile Size Width 40mm, Height 50-110mm Material Thickness 0.8-2.0mm, G300-G550 Zinc-Alum Steel Coil Operation System 21-inch Touchscreen Control System Self-developed Controlling Software Punching & Cutting Molds 1 single-hole mold, 1 double-hole mold, cutting Accuracy ±1mm Profile drawing:

Fully Automated Efficiency

The Hat Section Cold Roll Forming Machine enables a single operator to manage the entire process, optimizing labor efficiency while maintaining consistent production quality.

High Precision Design

Combining mature engineering, precise assembly, and rigorous material testing, this line guarantees superior accuracy for finished products.

Enhanced Productivity

The integration of a separate punching unit and a servo flying cutting system ensures continuous high-speed production without compromising quality.

Long-Lasting and Aesthetic Design

Components such as rollers and shafts are chrome-plated for enhanced corrosion resistance and a polished appearance, making the Omega Purlin Roll Former a valuable addition to the production line.

Hat Channel Roll Forming Machine

The model, a specialized Hat Section Cold Roll Forming Machine, is designed for the production of roof trusses and purlins. With 16 roll-forming stations and a 14kW hydraulic station, it delivers a versatile and cost-effective solution for manufacturers.

This system continuously processes coil strips into specific cross-section profiles with minimal maintenance. Moreover, the Omega Purlin Roll Former can create purlin profiles and hat sections featuring customized punching slots, meeting diverse customer needs.

Applications

- Roof trusses for construction projects.

- Roof purlins for structural trusses.

- Other steel components requiring precise roll forming.

-

Top Hat Section Cold Roll Forming Machine

Top Hat Section Cold Roll Forming Machine

More pictures of the machine: