Industrial upgrading of the supply and demand market of color steel plate pressing machine

With the beginning of China’s reform and opening up, the domestic economic growth rate has been growing rapidly for several years.China’s industry is also developing rapidly along the fast lane. The high degree of perfection of the industrial chain of various major and subordinate machinery subdivision fields has attracted worldwide attention.Color steel tile press equipment development in our region at the beginning of experience has been accumulated over decades, with the increasing demand of the market environment, innovative products ready and ancillary equipment is also emerging.Market supply also depends on market preferences to determine the quality of the product, ultimately depending on whether there is a customer market to pay for the product.First of all, it can be determined that the color steel tiles have an indispensable role in the construction of regional projects. The construction of the site and the blockage of the traffic isolation zone have a symbolic effect. This kind of partition effect has been popular.Color steel tile is a steel plate product with organic coating on the surface, which is mainly used in the construction industry.

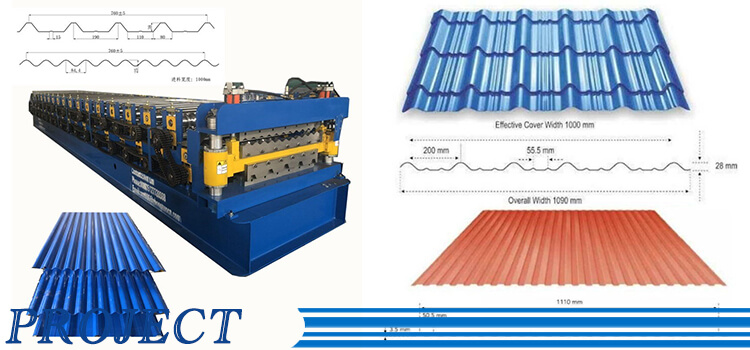

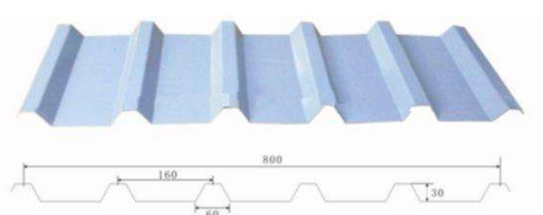

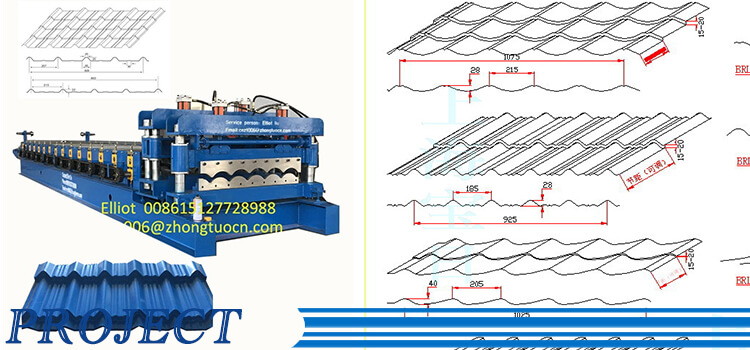

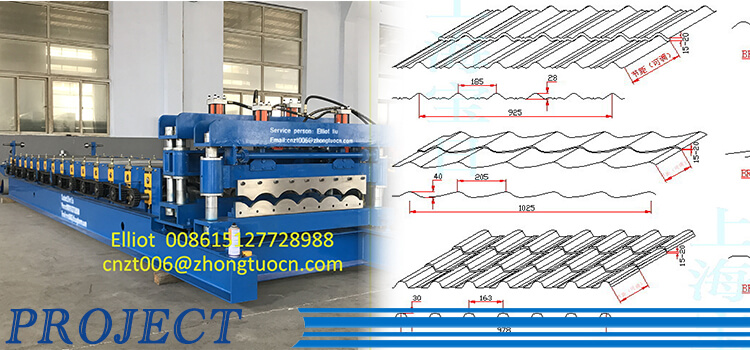

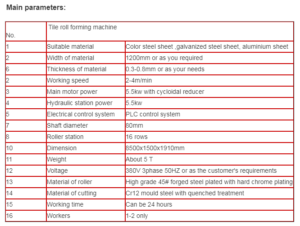

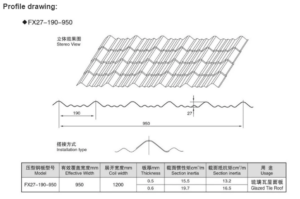

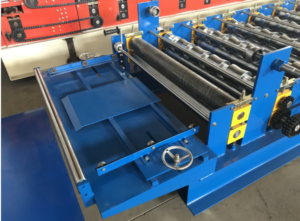

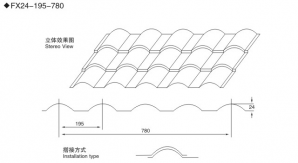

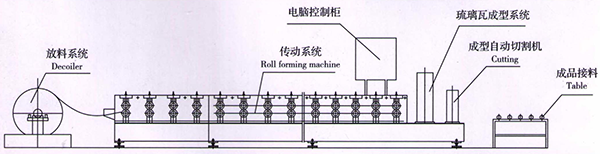

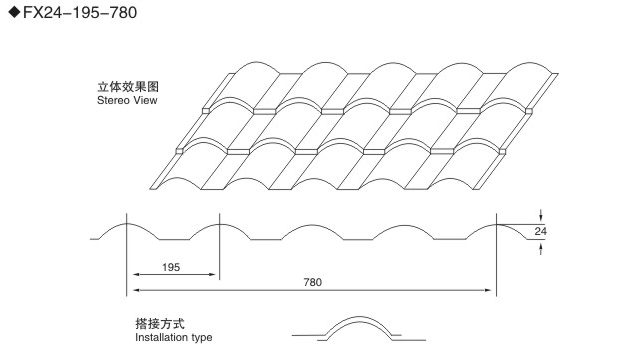

The color steel tile press equipment for producing color steel plate is also an indispensable upstream equipment in the color steel plate industry chain. These upstream and downstream components have created the current cold bending machine equipment industry.The color steel tile products produced by the color steel tile pressing machine have strong compression resistance and good flatness, and the subsequent installation of the product is convenient and fast. If no other alternative products appear, they are irreplaceable in the current market.

In the past, the market structure of the color steel industry in the Chinese market was mainly concentrated in the low-end industrial chain, which could only produce low-end products.In recent years, with the development of China’s economy, the market quality demand for product supply has also gradually increased.Break the traditional model of low-cost malicious competition.Forcing the cold bending forming industry to break through the initial dependence on the low-end market to achieve industrial upgrading.Eliminate low-end and low-quality manufacturers in the entire industry iteration.The scale of the industry is changing towards small and precise.