Metal color glazed tile making machine

Metal color glazed tile making machine

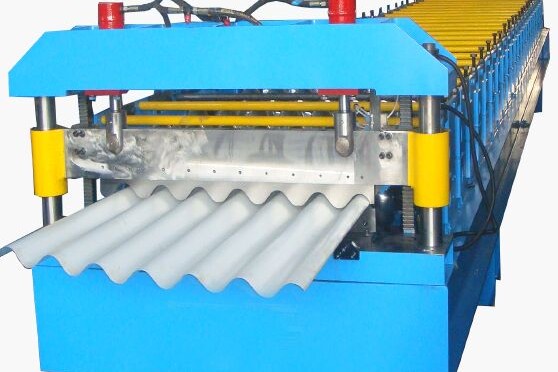

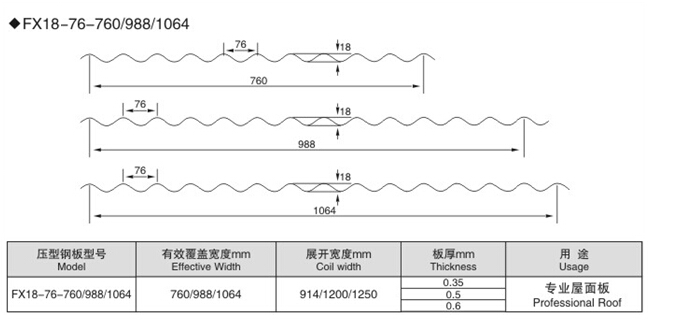

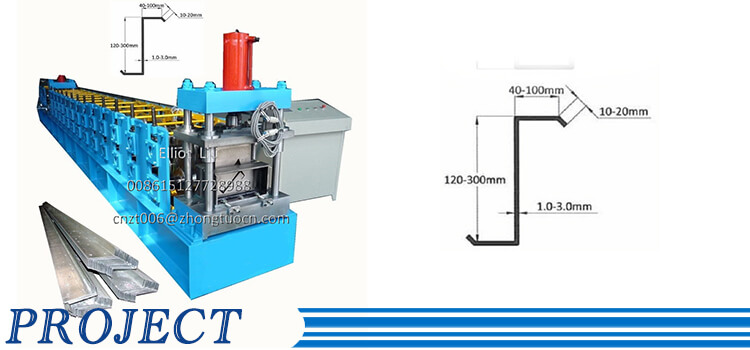

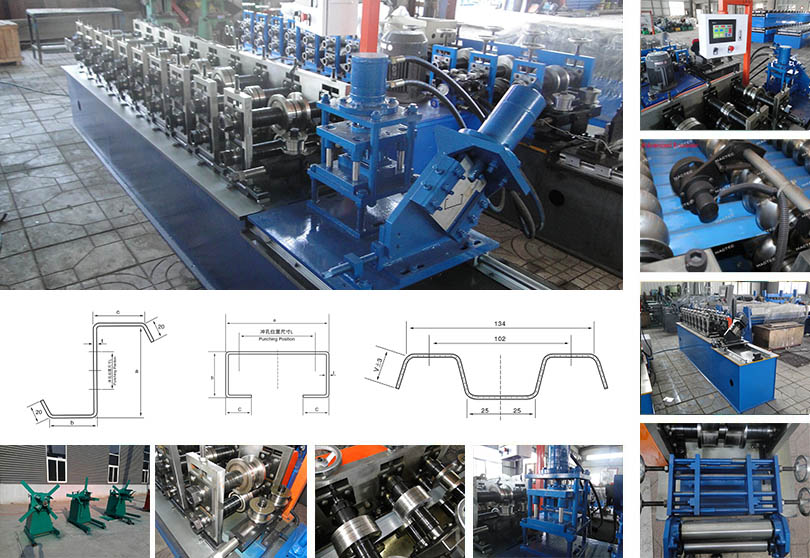

Metal color glazed tile making machine Roll Forming Machine of ZTRFM is designed to make roofing sheet with its distinctive advantages. It is durable with its service life stretching to 10 years. Besides that, its working speed highly stands at 8-22m/min. Metal glazed tile making machine is also called metal step tile making machine, or metal roofing sheet machine. Here are some drawing profile for your reference:

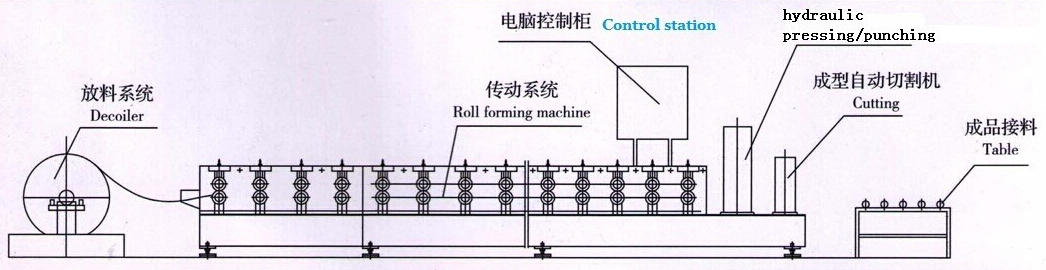

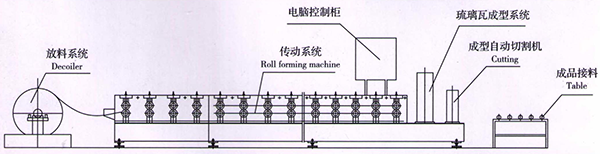

Working Process of a metal glazed tile making machine :

Uncoiling→ Feeding material into machine→ Roll forming→ Measuring length→ Step formed→ Auto cutting→ Products receiving

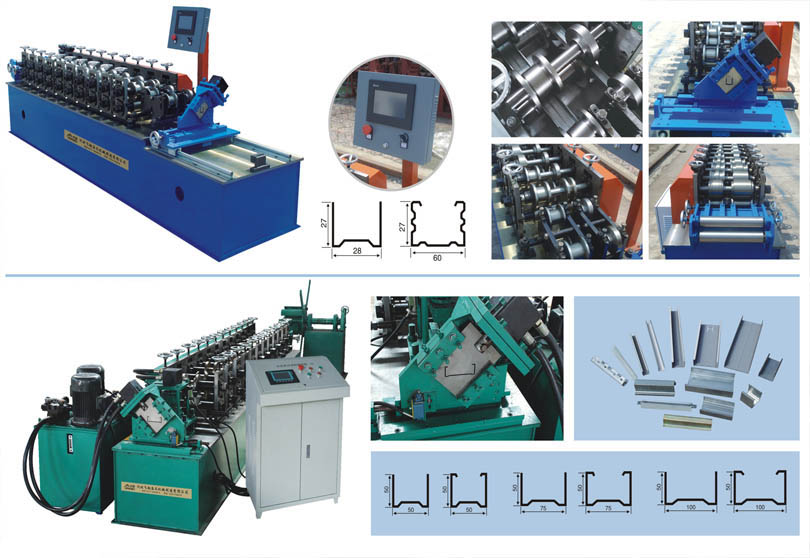

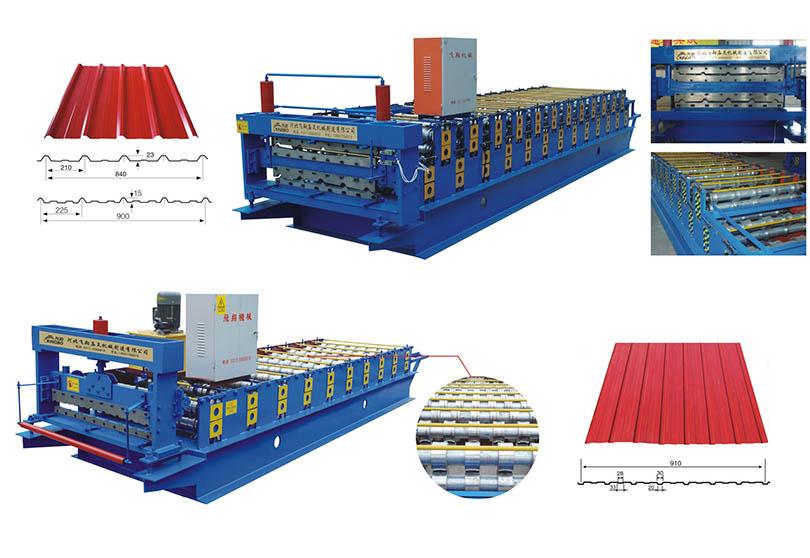

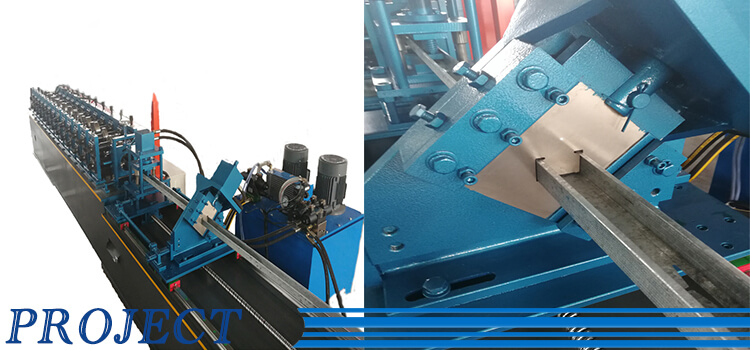

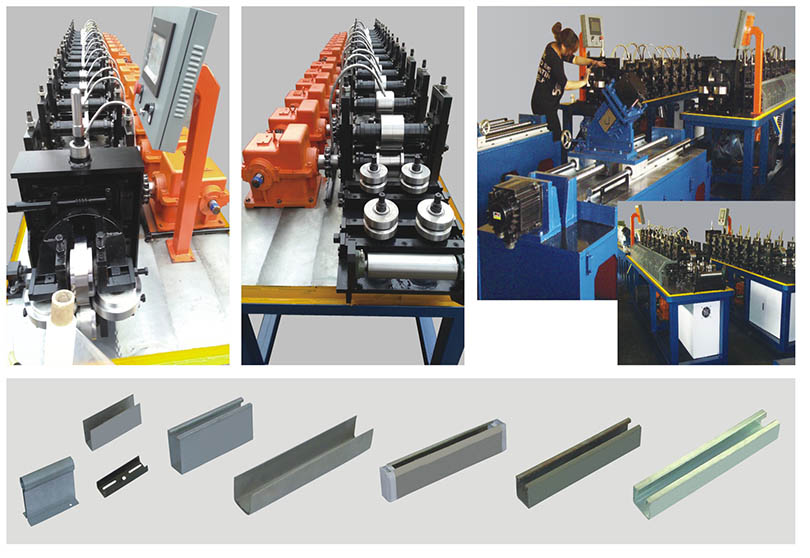

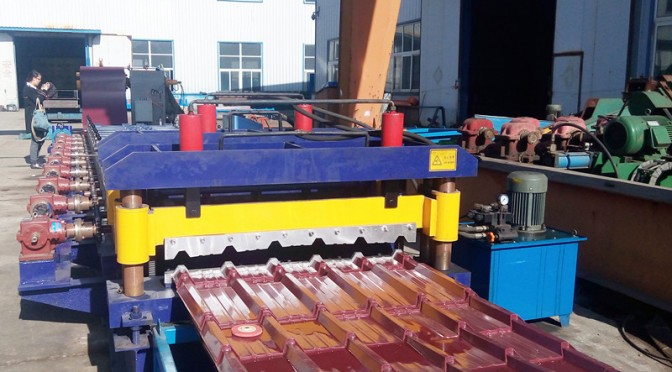

What does a finished glazed tile making machine look like?

Main parameters of glazed tile making machine:

| 1 | Length of the main part | About9500*1650*1500mm |

| 2 | Weight of main part | About 6.8 Ton |

| 3 | Voltage | 380V/50HZ3Phase (as customer’s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | Guide pillar and the thickness is 30mm |

| 6 | Frame thickness | 25mm |

| 7 | Drive mode | Gear |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ90mm Solid shafts |

| 11 | Number of rollers | 16 rollers |

| 14 | Main power | 11kw(Simon motor ) |

| 15 | Text screen displayer | Japan made |

| 17 | Forming speed | speed 8-22m/min |

| 18 | PLC Control system | Japan Panasonic PLC |

| 19 | Hydraulic power | 5.5KW |

| 20 | Gear box | China famous brand |

| 21 | Chain | 1.25 |

| 22 | Delivery time | 30 working days after receiving the deposit |

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

At ZTRFM, various payment terms are acceptable,you can choose what is convenient for you. Also we offer excellent after-sales services. Typically , we offer 1 year warranty and whole life technical support. Our engineers can work overseas and clients can also come to be trained to how to operate machines.

For more information, please contact me at Whatsapp:008618730769688 or send an email to cnzt005@zhongtuocn.com