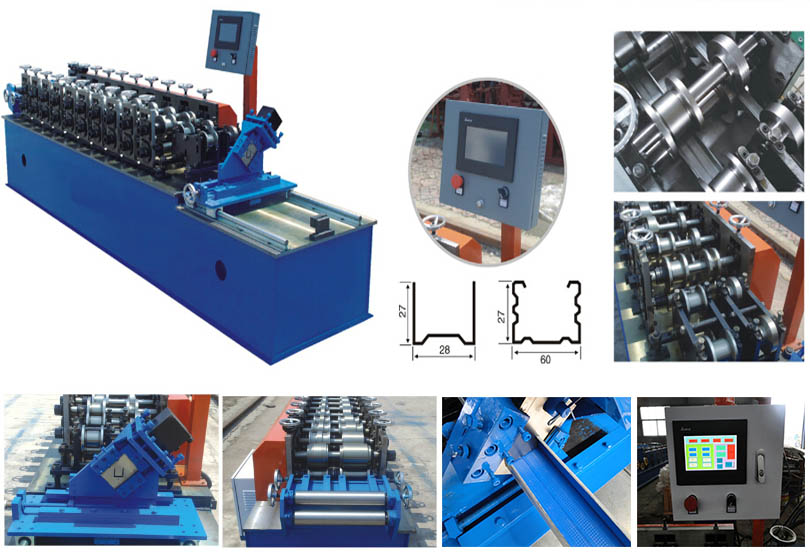

UD, CD metal stud roll forming machine, all-in-one combined light keel producer

Cater to the market requirement, Zhongtuo UD, CD metal stud roll forming machine was developed. Different with other roll forming machines, Zhongtuo metal stud roll forming machine supports both U shape and C shape metal track and stud making meanwhile sizes are options. So we call it as all-in-one combined light keel roll forming machine.

Features of UD, CD metal stud roll forming machine

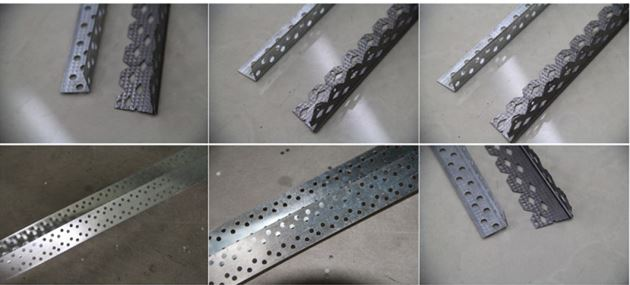

1. One machine either could be used to make U stud in various sizes

2. Able to make C stud in various sizes.

3. For making C and U without changing rollers.

4. Easy to adjust sizes just by sizing in computer.

5. Machine is controlled by PLC station.

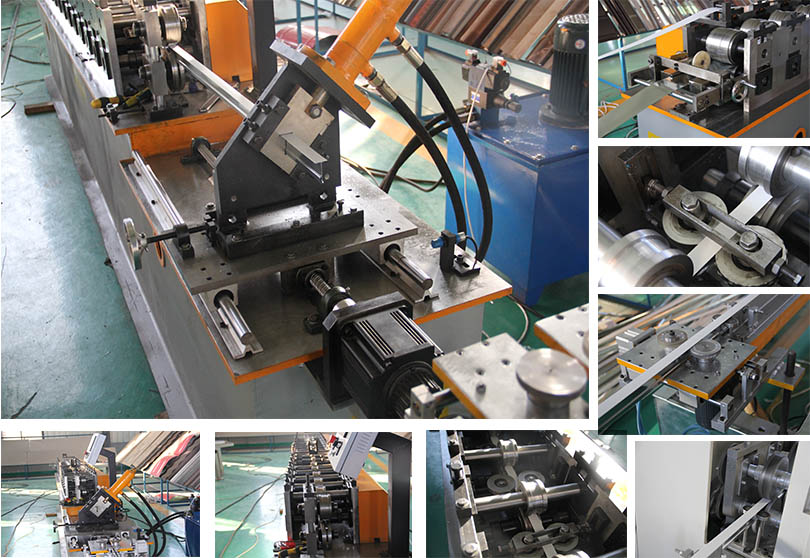

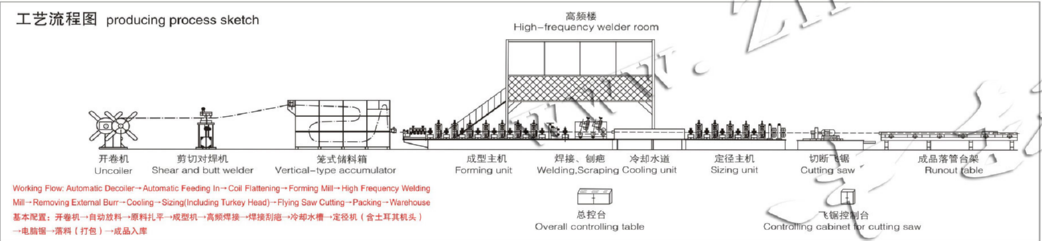

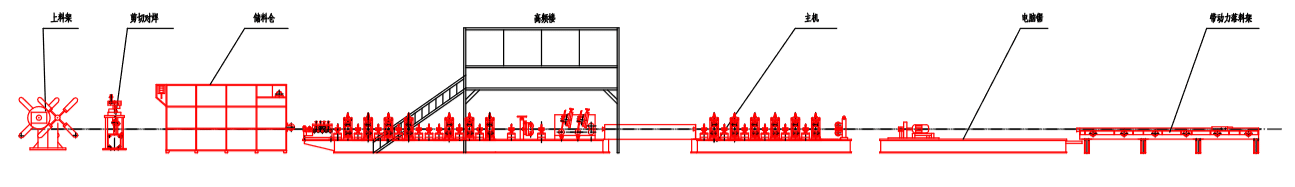

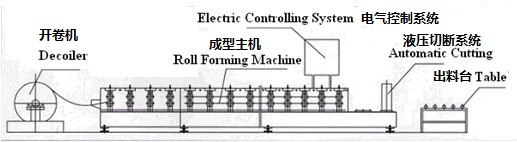

This machine is composed by the following parts: decloiler—-leveling system—-roll forming machine—-shearing and cutting part—-runout table.

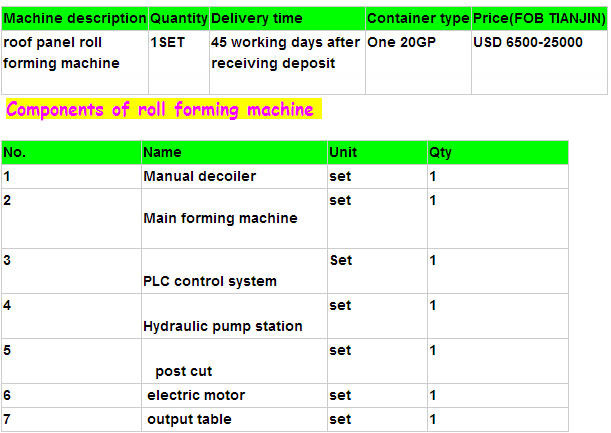

Here are some basic parameters of Zhongtuo UD, CD metal stud roll forming machine:

|

UD, CD metal stud roll forming machine |

|

| Supported material | Processing material: GI Material thickness: 0.4—1.0mm Material hardness: 550 MPA—350 MPA Formed width: 28/60mm Forming speed: 25m/min |

| Main part basic information | Machine size:3800…1200…1400 Weight of main part: 3 tons Roller fixer : Guide column Memorial arch frame type Frame thickness:25mm Drive mode: gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: φ40mm Number of rollers : 10 rollers Main power: 3kw |