Roof Panel Forming Machine Making Metal Construction Materials

Roof panel forming machine main structural features:

1, roof molding machine structure is simple, beautiful appearance, because the machine uses steel structure, the overall processing after welding, so the structure is simple and reasonable, strong deposit carrying capacity, smooth and reliable operation.

2, roof roll forming machine equipment of high quality forged steel 45 precision manufacturing, the surface of the hard chrome plating, to achieve high roll surface hardness, smooth, sheet molding surface without injury.

3, roof molding machine rollers 45 steel after quenching, in order to improve the strength, hardness and other mechanical properties of the shaft.

4, the main components of the electrical control system of all imports.

5, roof molding machine is fully automatic fixed length forming cut length precise positioning, plate-shaped head and tail neat appearance.

6, low roll forming equipment noise, high efficiency.

Specifications Roof Panel Forming Machine Making Metal Construction Materials:

1)CE.

2)14 months warranty

3)made to order.

4)10-year exper.

Roof Panel Forming Machine Making Metal Construction Materials:

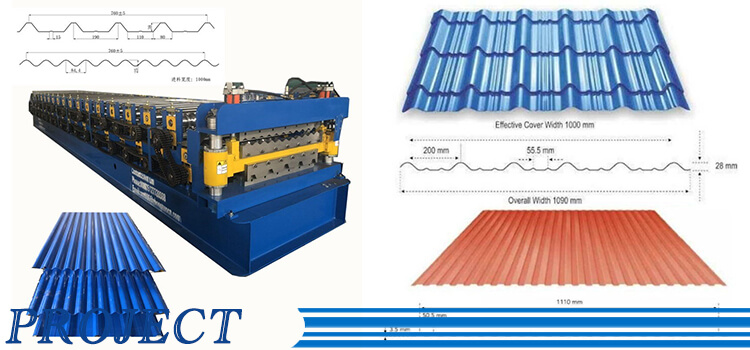

ALLSTAR MACHINERY:Roof Panel Roll Forming Machine,Roof Deck Roll Forming Machine,Roof Sheet Roll Forming Machine

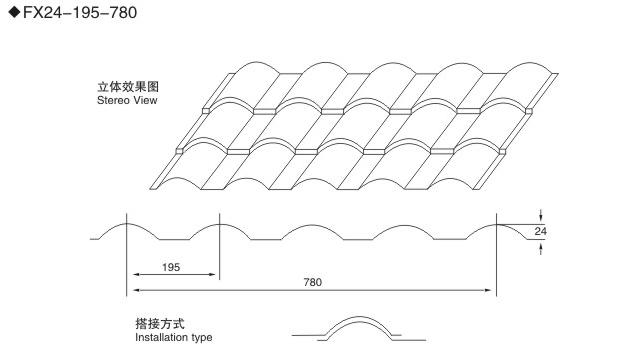

Specifications of Roof Panel Roll Forming Machine, Roof Deck Roll Forming Machine:

1. Material Width: 280mm & 260mm.

2. Material Thickness: 0.4mm-0.8mm.

3.Suitable Raw Materials: Pre-painted coil; Zinc coated plate.

4. Forming speed: 12-15m/min.

5. Forming Stations: 11

6. Material of rollers: Good 45#, rigid chrome coated.

7. Power of main motor: 3kw.

8. Dimensions: about 3800mm x 1200mm x 1380mm.

9. Power: 380V 50HZ 3phase 1 phase voltage 220V

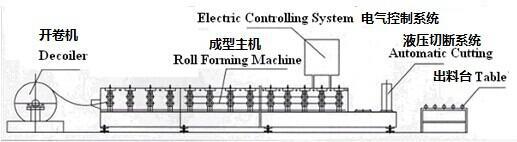

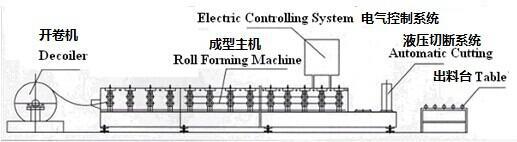

The equipment include:

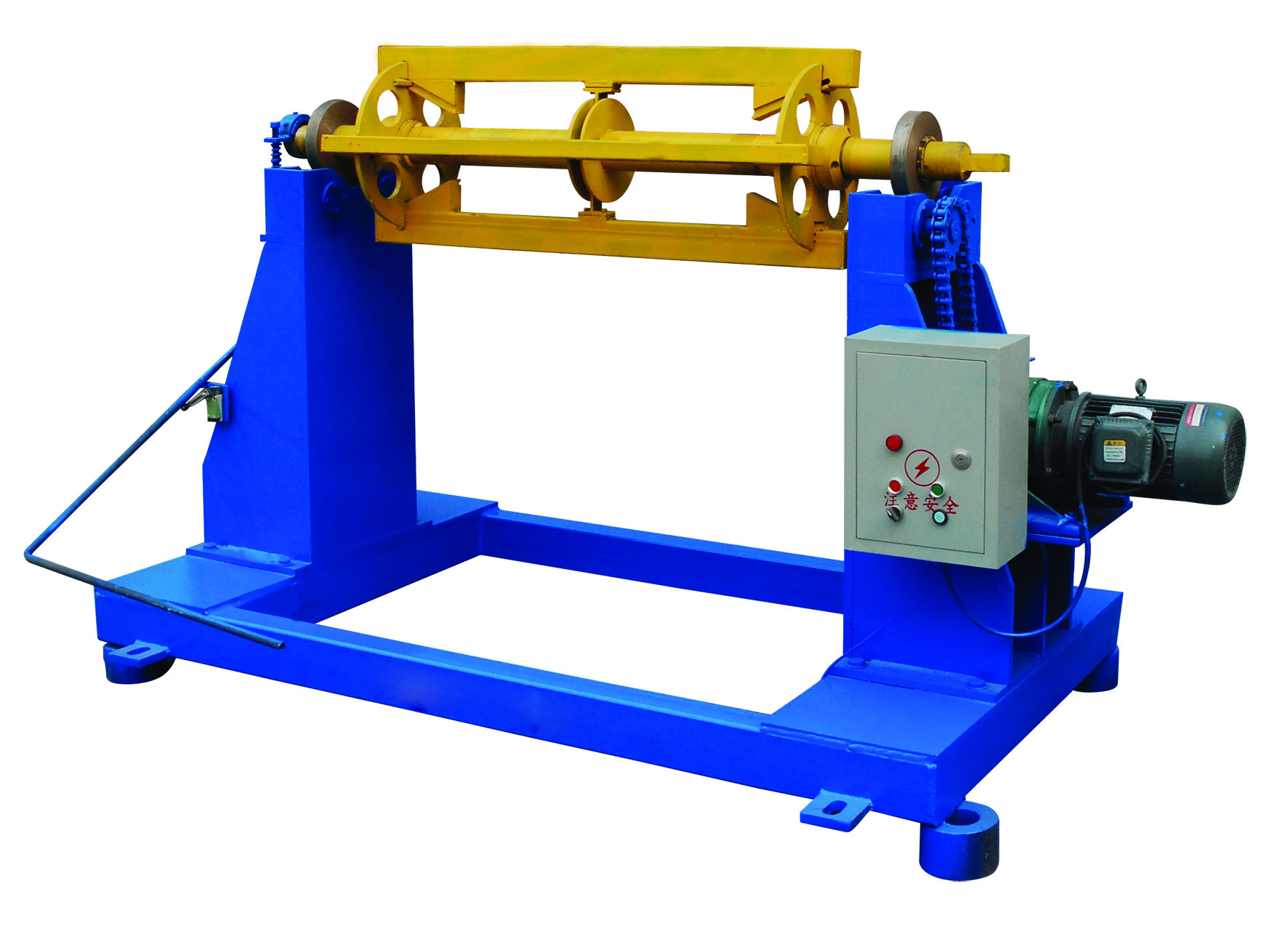

1. Un-coiler, 1 set

2. Main Roll forming machine, 1 set

3. Hydraulic cutting, 1 set

4. Hydraulic station, 1 set

5. Electric controlling system, 1 set

6. Product rack (un-powered), 1 set

7. Instruction Book, 1 piece

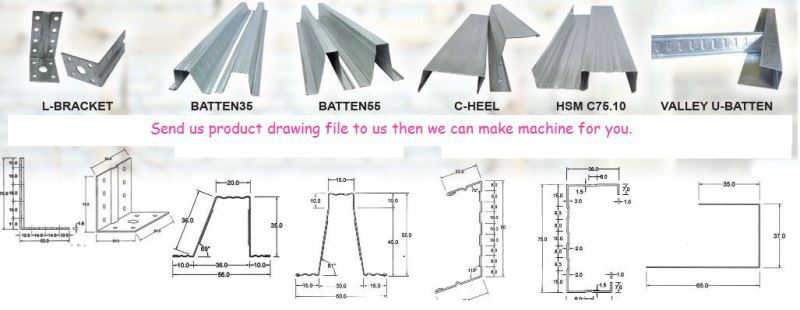

We can design and make according to customers requirement.

Major Products and Services:cold roll forming machine for corrugated tile, glazed tile, C Purlin, Z Purlin, roof panel and wall panel, etc.

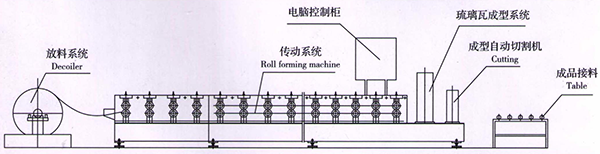

metal roofing roll forming machine production process

uncoiling–feeding material into machine–roll forming–measuring length–step formed–auto cutting–products receiving

1. Installation and training of machine manufacturer:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the roll forming machine for sale , and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service of roll forming machine for sale

a.One year guarantee for whole roll forming machine for sale.

b.24 hours technical support by email or calling

c.If there is any problem found of steel roof sheet roll forming machinery, we will repair roll forming machine for sale for free in one year.

The Roof Panel Forming Machine can custom made。If you need this type machine you can contact us .We will give you the price.

Office:Room 807, Building 6, Taida International, Yunhe District, Cangzhou, City, Hebei Province, CHINA

Factory:YingBin Road in Industrial Development Zone of Botou City,Hebei Province,CHINA

TEL:+86 317 5206885 TEL:+86 317 2191158 FAX:+86 317 5206880 PHONE:+86 15127778288 QQ:497059080

WEB SITE:http://www.rollsformingmachine.com/ MAIL:ceo@zhongtuocn.com

![A)A0L4OE5P[M$P[Q]GV]27N](http://www.rollsformingmachine.com/wp-content/uploads/2015/09/AA0L4OE5PMPQGV27N.jpg)