ZHONGTUO High Frequency welder pipe forming machine

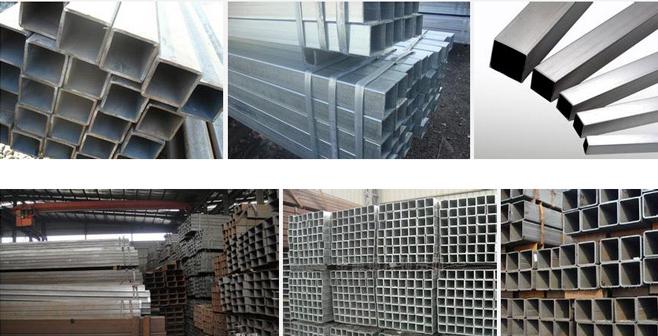

ZHONGTUO cold bending roll forming machinery factory is professional offering the high frequency welding pipe machines for making the round pipe, the square pipe and the rectangular pipe and the oval pipes.

The HF welder tube forming machine is one kind of the tube forming machine, the difference is that , there is a high frequency welding system to make the tube from seam to seamless. The same with some other cold bending machine is that, the HF welder tube forming machine also can produce different sizes bu changing the molds. It can make stainless pipe, carbon steel pipe in the shape of round pipe, square pipe, rectangular tube, oval pipe and others.

The features of the high frequency tube machine are as below:

1 High speed, the rube mill is with high frequency welding system and servo fly saw cutting system, so the speed can achieve 40 meters/min-110 meters/min

2 Can produce many shapes of pipe, can many size of each size tubes.

3 Cutting system is the servo fly saw cutting system.

One machine could be used to make various types and ranges steel pipes by changing moulds. For those who needs to run factory of steel pipe, just 3 sets of machines then you can cover steel pipe diameter range from 10-127mm within the material thickness from 0.4-5.0mm.

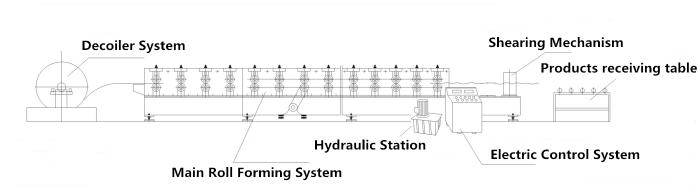

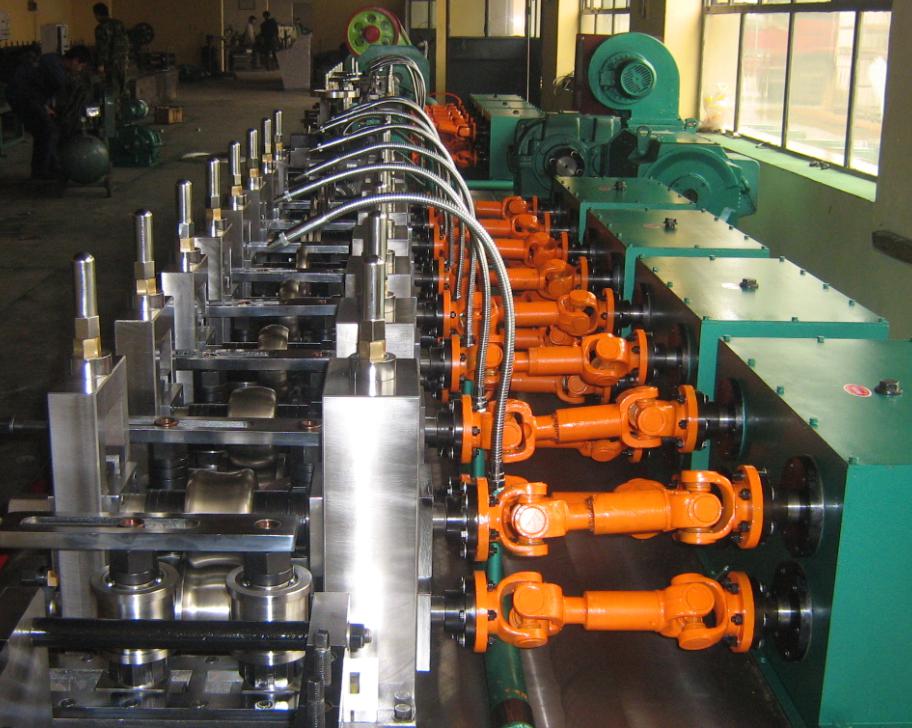

The flow of the high frequency tuber forming machine is as below:

Single-arbor un-coiler –’Strip-head Cutter and welder–

Spiral Accumulator—Forming sectionï Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller—De-burr frame —Cooling unit –Sizing unit and straightener –Flying saw under computer-control –Run-out table—straightening

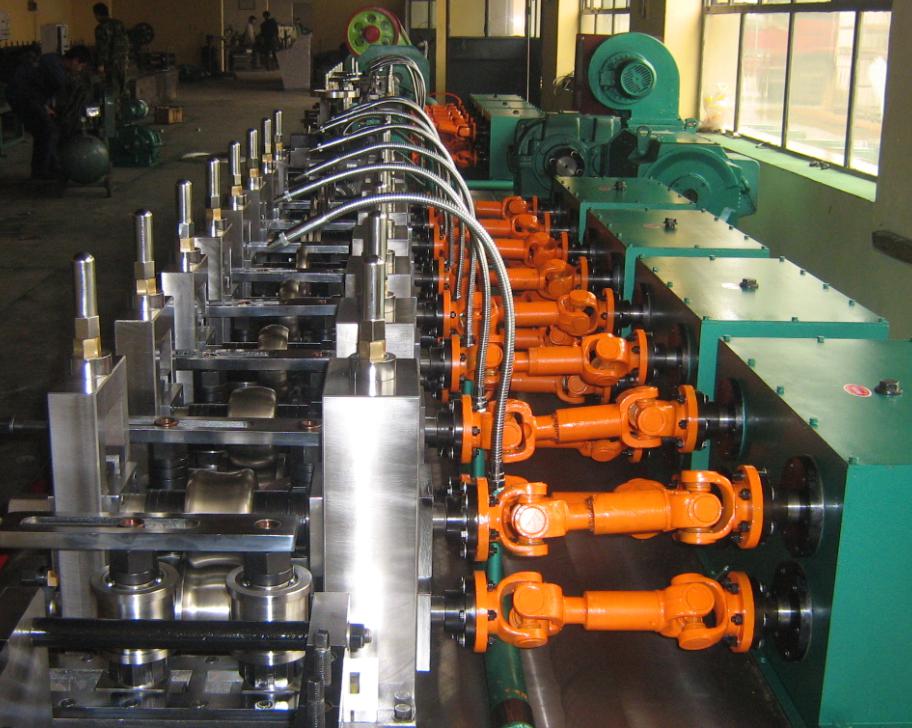

There are two kinds of high frequency tube forming machine,one high frequency tube forming machine is with cantilever structure, the forming rollers are on one side, and the power are o the other side. The other frequency is with Dragon Gate structure, similar to the ordinary cold bending roll forming machines.

Below are the pictures for your reference:

The cantilever structure high frequency tube forming machine

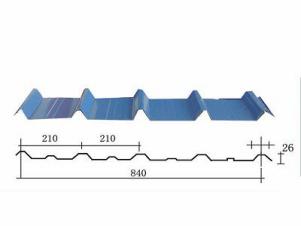

Stone coated base sheet Material 1.1 Coil material:color Sheet, galvanized sheet 1.2 Coil material thickness: 0.3mm- 0.6mm 1.3Feeding width:1250mm Stone coated roof tile line working flow : 1 Sheet shearing and slitting machines 2 Cutting flower edges machine 3 Hydraulic punching shapes 4 Base gel glue coating 5 Coating sand 6 First oven drying 7 Surface glue coating 8 Second oven drying

Stone coated base sheet Material 1.1 Coil material:color Sheet, galvanized sheet 1.2 Coil material thickness: 0.3mm- 0.6mm 1.3Feeding width:1250mm Stone coated roof tile line working flow : 1 Sheet shearing and slitting machines 2 Cutting flower edges machine 3 Hydraulic punching shapes 4 Base gel glue coating 5 Coating sand 6 First oven drying 7 Surface glue coating 8 Second oven drying