metal embossing machine

metal embossing machine

Embossed lines are mainly for producing embossed aluminum and steel roll. metal embossing machine is suitable for metal sheet, particle board, decorated materials, and so on. The pattern is clear and has strong third-dimension. It can be assorted with the embossing production line

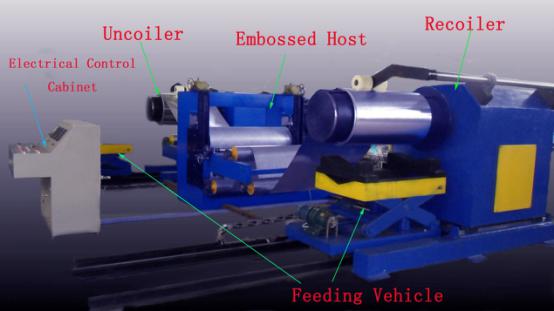

The main parts of this producing line

Uncoiler, embossed host, recoiler, electrical control station

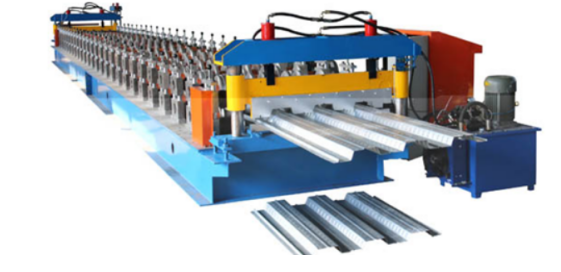

Here is our pic for your reference:

Suitable material: sheet coiled material, such as: aluminum, galvanized sheet, colorized painting steel plate and stainless steel.

Standard parameter of this line

| model | ZT-S1000 | ZT-S1400 | ZT-S1600 | ZT-S1900 |

| Overall size(mm) | 2900*1200*1500 | 3300*1200*1500 | 3500*1200*1500 | 3800*1200*1500 |

| Roller size | φ350*1000mm | φ380*1400mm | φ400*1600mm | φ450*1900mm

|

| Material of roller | 42CrMo | 42CrMo | 42CrMo | 42CrMo |

| Roller hardness | HRC55-58 | HRC55-58 | HRC55-58 | HRC55-58 |

| Way of embossing | Both up and down rollers embossing at same | Both up and down rollers embossing at same | Both up and down rollers embossing at same | Both up and down rollers embossing at same |

| Embossing regulation | By screw | By screw | By screw | By screw |

| Motor power(KW) | 7.5 | 11 | 15 | 15 |

| Line speed | 0-18m/min | 0-30m/min | 0-40m/min | 0-45m/min |

Detailed parameters of this metal embossing machine line

1. Roller specifications: DIA450~500mm, width: 1000~1800mm.

2. Take the roll surface hard chromium plating

3. Suitable for pressing plate: 2-6 mm

4. Frame steel plate welded structure, polished, tempering, machining, solid wall plate Q235 90 mm thick

5. Pattern processed by laser engraving.

6. The pattern making: according to the buyer to provide the sample pattern

7. Pressure mode: hydraulic 50~100T.

8. Working speed: 1~20m/min, speed changed by frequency converter .

9. Voltage 380V/50Hz/3PH

10. Safety shield shell

11. Generous beauty of appearance

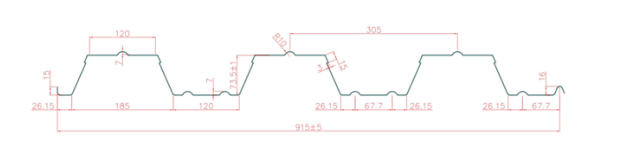

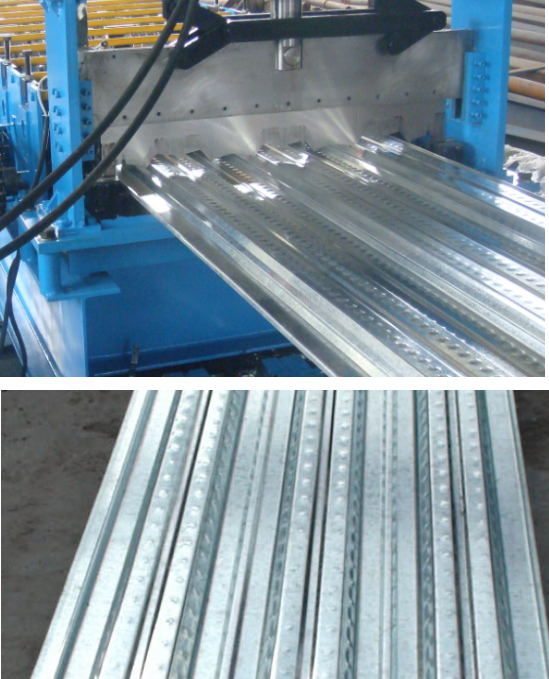

Here are some pics of embossing pattern for your reference:

ngs and then we design the machine for you.

ngs and then we design the machine for you.