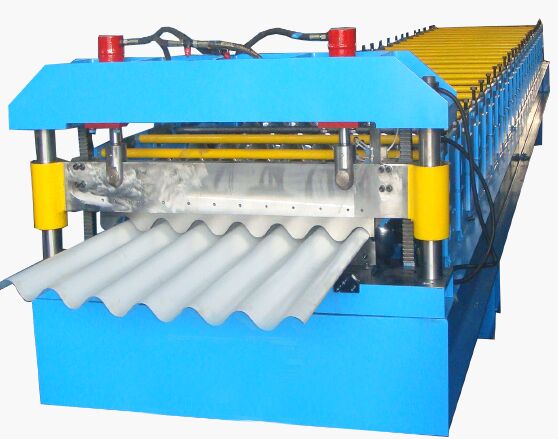

Corrugated Sheet Roll Forming Machine

Corrugated Sheet Roll Forming Machine

Machine Description Corrugated Sheet Roll Forming Machine Roof Panel Machine

To carer for customer’s differrent request, we can customize our Corrugated Sheet Roll Forming Machine Roof Panel Machine as to clients’ drawings or requirement.If you want the price, pls help us to confirm the machine types and engineering drawings at first.This types of machine is widely use in producting of metal roof panle making machine for its practicability and reasonable price.Additionally the roof panel made by it is very popular in the market.

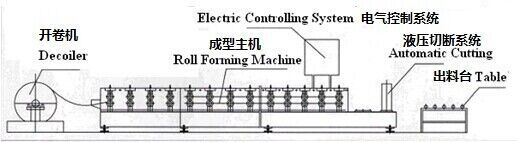

Production Process of Corrugated Sheet Roll Forming Machine Roof Panel Machine

Uncoiling—–Feeding material into machine—–Roll forming—–Measuring length—–Auto cutting—–Products receiving

More pictures about our Corrugated Sheet Roll Forming Machine Roof Panel Machine

Parameters of Corrugated Sheet Roll Forming Machine Roof Panel Machine

Material Type:GI/PPGI/AL

Material Width:1000/1200/1220/1250mm(customized)

Material Thickness:0.3—1mm

sheet length:any length

Length Tolerance:±2mm/6m

Working Speed:8m/min(standard machine)

Control System:Mitsubishi/Siemens PLC& transduce(customized)

Total Power:About8.5 KW

Total Weight:About 10T(up to final design)

Loading-capacity:5 T

Uncoiling-width:1000/1200/1250 mm

Inner-diameter: 450-550 mm

Frame : 350 H steel

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Length of the main part:8650*1650*1500 mm

Voltage:380 V/50 HZ 3 Phase

Roller fixer : middle plate

Material of shafts: 45#steel

Diameter of shafts: 80 mm

Number of rollers : 18 rollers

| Delivery date | 25 working days |

| Payment Method | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

| Warranty |

|