Corrugated Steel Sheet Glazed Tile Making machine

Corrugated Steel Sheet Glazed Tile Making machine

The roofing tile formed by cold roll forming machine outperforms traditional roof tile with their elegant appearance and suit every architecture design. With light weight, strong strength and long service life, it is convenient to install in a short time.

The corrugated steel sheet glazed tile making machine is designed for continuously roll forming and pressing step tiles upon series of product profile. The length can be set up or unlimited and the depth of each step can stretch from 10 to 30mm and is adjustable.

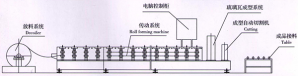

This roofing tile roll forming line consists of a hydraulic single head type uncoiler, a roll forming main machine, a hydraulic forming tile machine, a hydraulic automatic cutting machine, a products run out table, and a PLC automatic control cabinet.

Un-coiler System of Corrugated steel sheet glazed tile making machine

Usage: support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Coil feeding part of Corrugated steel sheet glazed tile making machine

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

Forming device of Corrugated steel sheet glazed tile roll forming machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Feature: Ensure stability, precision and lifetime.

Step-formed mechanism of Corrugated steel sheet glazed tile roll forming machine

Feature : it is used to make the step , the glazed tile’s final formed

Cutting device of Corrugated steel sheet glazed tile roll forming machine

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

(include cutting tools, hydraulic tank, cutter machine)

Controlling device of Corrugated steel sheet glazed tile roll forming machine

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

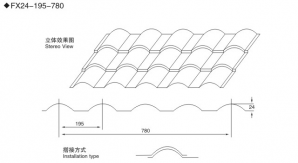

Processing material: colored steel plate, galvanized plate, or aluminum plate

Material thickness: 0.3—0.8mm

Material hardness:195 mpa—350 mpa

Material width: 1000/1250mm

Formed width:828/1035mm

Wavelength: 207 mm

Step height: 28mm

Step length:150mm—380mm(adjustable)

Forming speed: 8-12m/min

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

At ZTRFM, various payment terms are acceptable,you can choose what is convenient for you. Also we offer excellent after-sales services. Typically , we offer 1 year warranty and whole life technical support. Our engineers can work overseas and clients can also come to be trained to how to operate machines.

For more information, please contact me at Whatsapp:008618730769688 or send an email to cnzt005@zhongtuocn.com