Customizable Versatile Wall & Soffit Panel Roll Forming Machine Soffit Roll Former

Features of the Wall / Soffit Panel Roofing Machine

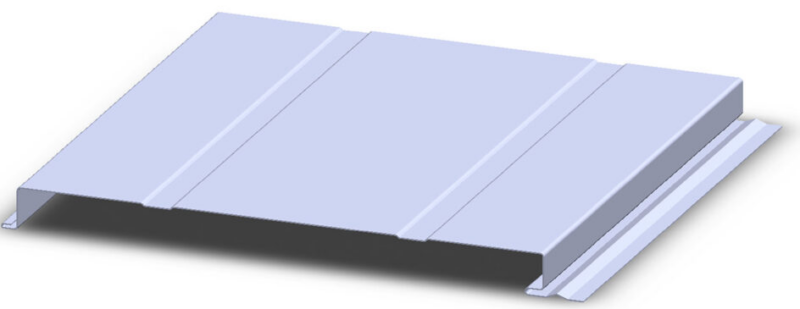

This equipment is designed for producing 1″ wall and soffit panels, offering versatility for various commercial application.

Frame Construction

The machine frame is constructed from structural steel and welded into a robust, rigid structure. It is precision-machined to ensure a perfectly flat surface for assembling the forming stations. Adjustable leveling feet are included, allowing the machine to be set precisely level during installation.

Forming Stations

All forming rolls that come into contact with the painted surface of the conductor pipe are coated with hard chrome. This coating ensures extended roll durability and maintains the pristine finish of the pipe.

Superior Drive System

Every station on the machine, both top and bottom, is equipped with drive mechanisms. These stations are spring-loaded, ensuring consistent material tension and minimizing the need for manual adjustments. This spring design makes the machine exceptionally versatile, allowing it to handle a variety of materials seamlessly.

Wall / Soffit Panel Roofing Machine Overview

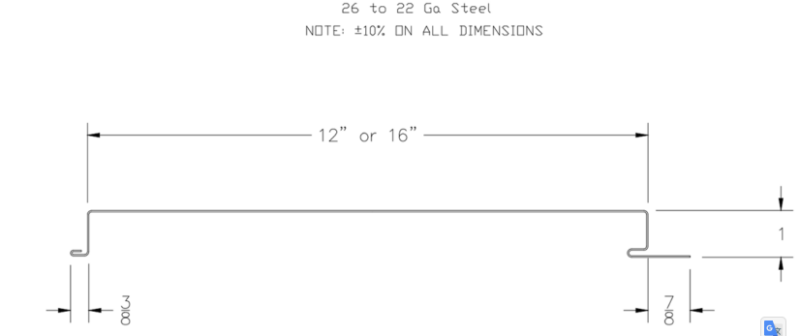

– Creates panels with 11″, 12″, or 16″ coverage widths.

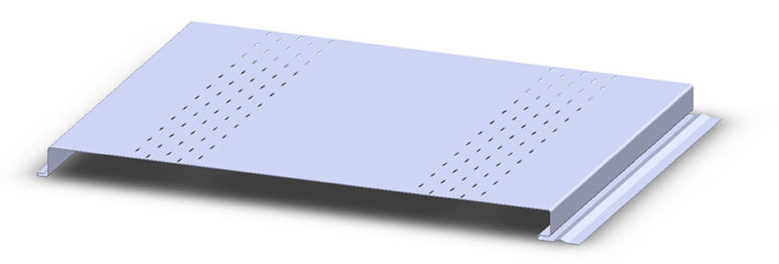

– Can perforate steel materials up to 24 gauge.

– Utilizes a patented independent drive mechanism for enhanced performance.

– Equipped with free-spinning rollers crafted from 304 stainless steel.

– Built on a robust 2″ tubular steel frame for durability.

– Enables quick transitions between panel sizes for efficient operation.

Profile drawing:

Wall / Soffit Panel Roofing Machine Specifications

– Dimensions: Length: 120″, Height: 25″, Width: 44″

– Weight: 2,800 lbs.

– Production Speed: Up to 60 feet per minute.

– Motor Power: 5 HP, 220V AC, single-phase electric motor.

– Shearing Mechanism: Hydraulic.

– Coil Width Requirements:

– 15″ for 11″ panels.

– 16″ for 12″ panels.

– 20″ for 16″ panels.

– Compatible Materials:

– Steel up to 22 gauge.

– Aluminum up to 0.032″ thickness.

– Copper up to 20 ounces.

Wall / Soffit Panel Roofing Machine Standard Features

– Fabricates panels in 11″, 12″, and 16″ widths.

– Includes tooling made from 304 stainless steel for precision.

– Comes with a stiffening rib assembly for added panel strength.

– 4,000 lb capacity expandable decoiler with brake and stand.

– Equipped with a limit switch measuring device for accuracy.

– Operated via handheld remote controls.

– Industrial-grade hydraulic system for reliability.

– Features a hydraulic shear with notching for simplified assembly.

– Powered by a 220V electric motor.

Wall / Soffit Panel Roofing Machine Optional Upgrades

– Perforation Unit: Adds the ability to perforate panels.

– Gasoline Engine: For portable, off-grid operations.

– Vinyl Cover: Provides protection during transportation or storage.

– Run-Out Stands: Adjustable height stands available in 50′ lengths.

– Digital Batch Controller: Ensures precise batch processing.

– Dual Power System: Supports multiple power sources.

– Over-the-Top Decoiler Mounting System: For space-saving operation.

– Trailer Configuration: Contact for details on mobile setup options.

The Technical Specifications Of The Soffit Panel Machine:

| NO | Name | Specifications |

| 1 | Raw material | Aluminum, PPGI |

| 2 | Raw material thickness | 0.3-0.5mm(22-26 gauge) |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 22 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 70mm |

| 7 | Work speed | 0-30m/min |

| 8 | Transmission | by single chain transmission |

| 9 | Motor power | 7.5kw motor |

| 10 | Machine frame | 350# H steel welded |

| 11 | Cutting type | Hydraulic fly cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | GB-Cr12 |

| 15 | Hydraulic motor power | 5.5KW |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |