Full-Automatic High-Speed Lightweight Drywall Stud and Track Roll Forming Machine for Framing Systems

Stud And Track Roll Forming Machine

Specification:

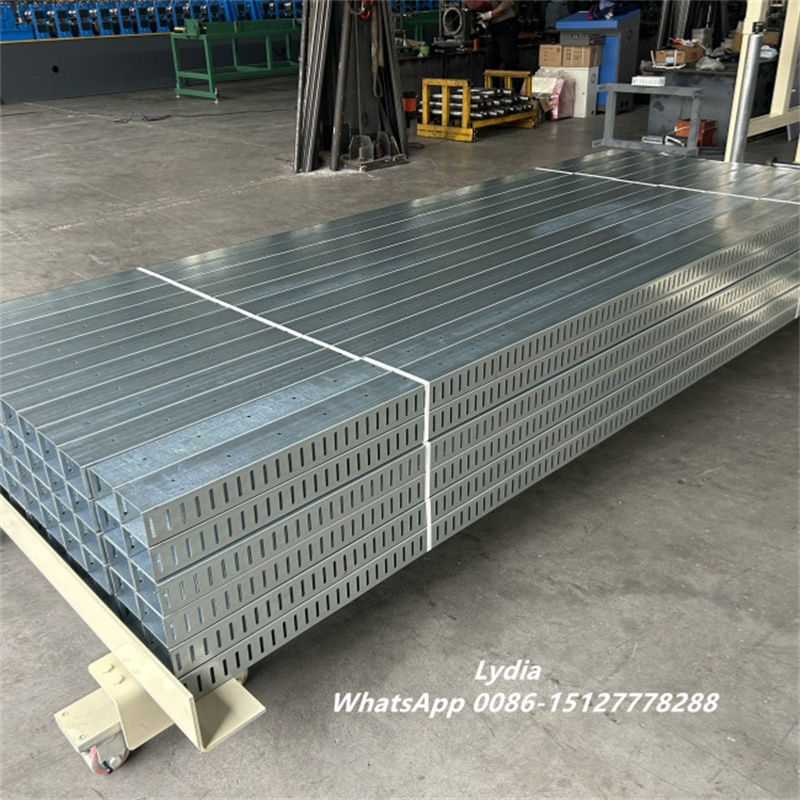

1. Material: G.I. Galvanized steel, Aluzinc

2. Material Thickness: According To Customer’s Requirement

3. Profile Width: As Requirement

4. Profile Height: Customized

5. Whole Production Line Speed: 60 – 70 Meters / Minute, Could Be Up To 100 Meters Per Minute.

Details Information:

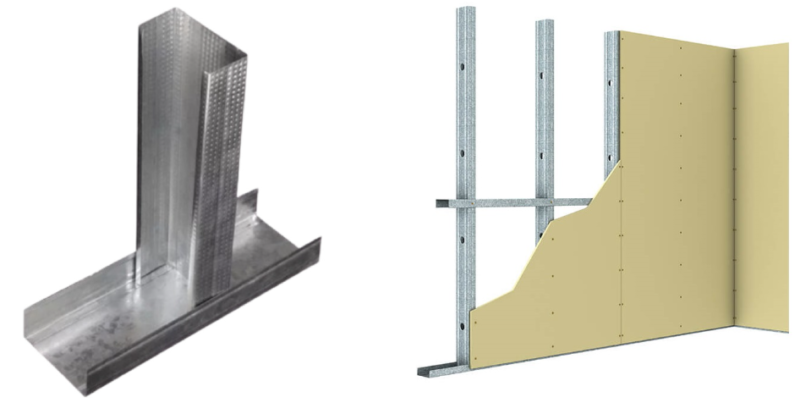

Metal framing components include furring channels, carrying channels, studs, tracks, wall angles, and main frame channels, all of which are essential for constructing concealed grid gypsum ceilings in lightweight structures. Strong,lightweight,simple to install,and available in a variety of sizes,metal studs and channels provide for the ideal and cost-effective wall and ceiling applications when used with several layers of gypsum board.

C stud & Track Roll Forming Machine,100% made by ZTRFM ,is to fully produce automatically the production of Stud and U Track with options for punching holes and embossing customer logos.Their main advantages are stable operation with a strong body frame and beautifully customized designs.

We have the following speed options :

Normally 25 to 35 meter per minute without punching

High speed is from 50 to 75 meter per minute with punching

Highest speed now we can reach 120 meter per minute with punching.

Adjustment options.

We have manual adjustment by spacer.

We have PLC control fully automatic type.

Profile drawing:

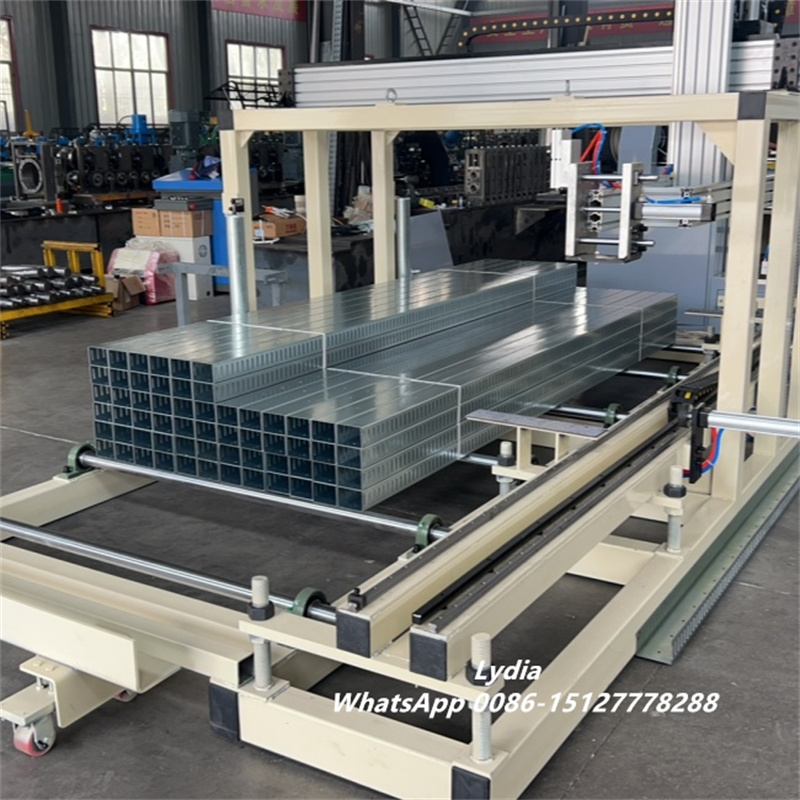

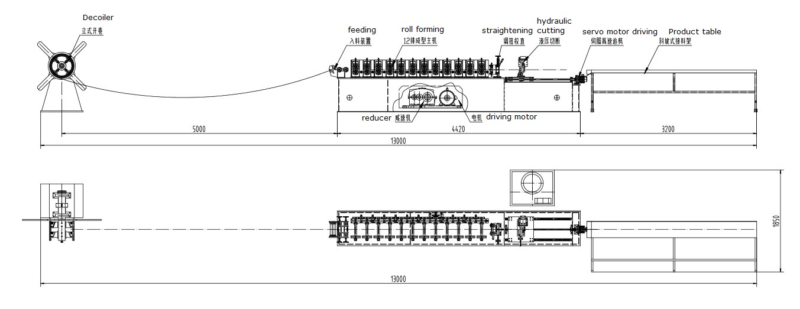

Machine Flow Chart Layout:

The Technical Specifications Of The Drywall Stud And Track Roll Forming Machine :

|

Ztrfm Drywall Stud And Track Roll Forming Machine |

||

| 1.Formed Material | Galvanized steel, Aluzinc | Thickness:0.2-0.8mm |

| 2.Decoiler | Hydraulic automatic decoiler | Hydraulic expansion, can save labor, easy and fast operation. |

| 3.Main body | Roller station | 11 rows(As your requirement) |

| Diameter of shaft | 50 mm solid shaft | |

| Material of rollers | Cr12, with heat treatment HRC 58-60 | |

| Machine body frame | Iron cast molding frame | |

| Drive | By gearbox, as per customer’s requirement | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Production line speed | 0-70m/min | |

| 4.Cutter | Automatic | Flying cutting.Cutter material: cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 11KW |

| Hydraulic system power | 7.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-70 m/min | Speed is adjustable according to customer’s request |

More pictures of the machine: